If you're an electronic hobbyist looking to master soldering while adhering to international standards, you might be searching for terms like IEC soldering for beginners or simple IEC soldering guide. The good news is that IEC-compliant soldering is achievable even for those just starting out. This guide will walk you through the basics of soldering techniques for hobbyists, focusing on how to align with IEC standards for safety and quality in electronics projects.

In the sections below, we’ll dive deep into the essentials of electronics soldering for beginners IEC standards, covering tools, techniques, and best practices. Whether you're building a small circuit or repairing a device, this blog will equip you with the knowledge to solder effectively and meet global benchmarks.

What Are IEC Standards and Why Do They Matter for Soldering?

IEC, or the International Electrotechnical Commission, is a global organization that sets standards for electrical and electronic technologies. These standards ensure safety, reliability, and consistency in products and processes, including soldering for electronic assemblies. For hobbyists, following IEC guidelines might seem like an extra step, but it’s crucial for creating safe, durable, and professional-quality projects.

One key standard related to soldering is tied to the IPC J-STD-001, often referenced alongside IEC principles. It outlines requirements for soldered electrical and electronic assemblies, focusing on materials, methods, and inspection criteria. By adhering to such standards, you reduce risks like short circuits, component damage, or even fire hazards—issues that can arise from poor soldering practices.

For beginners, the takeaway is simple: IEC-compliant soldering means using the right tools, materials, and techniques to ensure your work is safe and reliable. Let’s explore how to get started with basic soldering methods IEC.

Essential Tools for IEC-Compliant Soldering

Before you begin soldering, having the right tools is critical to meeting IEC standards and ensuring quality results. Here’s a breakdown of the must-have equipment for hobbyists diving into soldering techniques for hobbyists.

1. Soldering Iron or Station

A reliable soldering iron is your primary tool. For beginners, a temperature-controlled soldering station is ideal because it allows precise heat settings, which is vital for IEC compliance. Look for a model with a wattage between 20-60W and a temperature range of 200-400°C (392-752°F). Excessive heat can damage components, while insufficient heat leads to weak joints—both of which violate quality standards.

2. Solder Wire

Use lead-free solder wire with a rosin core, as it’s safer and aligns with environmental and safety regulations often referenced in IEC standards. A common composition is 96.5% tin, 3% silver, and 0.5% copper (Sn96.5Ag3Cu0.5), with a melting point around 217°C (423°F). The diameter should be between 0.5mm and 1mm for most hobbyist projects.

3. Flux

Flux helps clean the surfaces being soldered and improves solder flow, ensuring strong connections. Opt for a no-clean flux pen for ease of use, as residue from improper flux can lead to corrosion—a concern under IEC guidelines.

4. Desoldering Tools

Mistakes happen, especially when learning electronics soldering for beginners IEC standards. A desoldering pump or braid is essential for removing excess solder without damaging components or circuit boards.

5. Safety Gear

Safety is a cornerstone of IEC standards. Always wear safety glasses to protect your eyes from solder splashes. Work in a well-ventilated area or use a fume extractor to avoid inhaling harmful fumes from solder or flux.

Understanding Basic Soldering Techniques for Hobbyists

Now that you have the tools, let’s cover the fundamental soldering techniques for hobbyists that align with IEC principles. These methods focus on creating strong, reliable joints while minimizing damage to components.

Step 1: Prepare Your Workspace

Set up a clean, stable workspace with good lighting. Use a heat-resistant mat to protect surfaces. Ensure all components and tools are within reach to avoid unnecessary movement while soldering, which can lead to accidents or poor joints.

Step 2: Tin the Soldering Iron Tip

Before soldering, apply a thin layer of fresh solder to the tip of your iron. This process, called tinning, prevents oxidation and ensures better heat transfer. A clean, tinned tip is essential for creating joints that meet IEC quality standards.

Step 3: Heat the Joint, Not the Solder

Place the soldering iron tip on the joint (where the component lead meets the circuit board pad) for 2-3 seconds to heat it. Then, touch the solder wire to the joint—not the iron tip. The solder should melt and flow evenly around the connection within 1-2 seconds. If it takes longer, your iron might be too cold, risking a weak “cold” joint, which fails IEC inspection criteria.

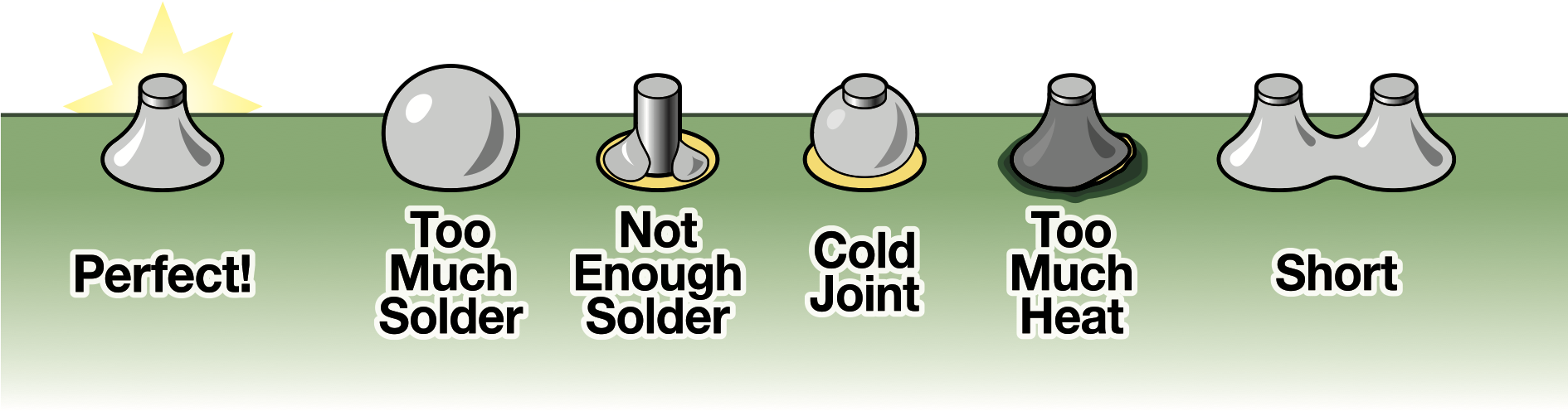

Step 4: Inspect the Joint

A good solder joint should look shiny and concave, fully covering the pad and lead without excess solder. According to standards like IPC J-STD-001, which aligns with IEC principles, there should be no cracks, voids, or solder bridges (unintended connections between pads). If the joint looks dull or uneven, reheat and apply more solder or flux as needed.

Step 5: Clean Up

After soldering, clean the board with isopropyl alcohol and a brush to remove flux residue. Leftover residue can cause corrosion over time, violating IEC reliability standards.

Common Mistakes to Avoid in IEC Soldering for Beginners

As you learn IEC soldering for beginners, it’s easy to make mistakes that compromise quality and safety. Here are some pitfalls to watch out for:

- Overheating Components: Applying heat for more than 5 seconds can damage sensitive parts like capacitors or ICs. Use a heat sink (like a small alligator clip) on leads to absorb excess heat.

- Using Too Much Solder: Excess solder can create bridges, leading to short circuits. Aim for just enough to form a small, smooth fillet around the joint.

- Ignoring Safety: Skipping ventilation or protective gear can expose you to toxic fumes or burns. Always prioritize safety to align with IEC recommendations.

- Poor Joint Preparation: Dirty pads or leads prevent proper solder adhesion. Clean surfaces with flux before soldering for reliable connections.

By avoiding these errors, you’ll produce work that not only functions well but also meets the high standards expected in professional electronics.

How IEC Standards Impact Soldering Materials and Processes

IEC standards influence every aspect of soldering, from the materials you use to how you inspect your work. Let’s break down key areas where these standards apply to basic soldering methods IEC.

Material Selection

IEC guidelines often emphasize environmentally friendly and safe materials. For instance, lead-free solder is preferred to reduce health and environmental risks. Additionally, components and circuit boards should be rated for the temperatures and conditions they’ll face during soldering, typically outlined in datasheets with values like thermal resistance or maximum soldering temperature (e.g., 260°C for 10 seconds).

Process Control

Consistency in soldering processes is a major focus of IEC standards. This means maintaining a stable iron temperature (e.g., 300°C for most through-hole components) and applying solder in a controlled manner. Variability in heat or technique can lead to inconsistent joints, failing quality checks.

Inspection and Testing

After soldering, IEC-aligned standards like IPC J-STD-001 require visual inspection for joint quality. Joints must be free of defects and meet specific criteria, such as a fillet angle of approximately 45 degrees for through-hole components. For hobbyists, a magnifying glass or loupe can help spot issues like cracks or insufficient solder.

Tips for Mastering Electronics Soldering as a Beginner

Becoming proficient in electronics soldering for beginners IEC standards takes practice and patience. Here are actionable tips to help you improve:

- Start Small: Practice on simple kits or scrap boards before tackling complex projects. Soldering LEDs or resistors onto a practice board builds confidence.

- Control Heat: Use the lowest effective temperature to avoid damaging components. For most hobbyist work, 280-320°C (536-608°F) is sufficient.

- Work Quickly: Limit heat exposure to 3-5 seconds per joint to prevent thermal stress, a key concern in IEC guidelines.

- Keep Tools Clean: Regularly wipe your soldering iron tip with a damp sponge and re-tin it to maintain performance.

- Learn from Resources: Watch tutorials or read guides focused on simple IEC soldering guide techniques to reinforce your skills.

Why Hobbyists Should Care About IEC Compliance

You might wonder why a hobbyist should bother with IEC standards when building personal projects. The answer lies in the benefits of quality and safety. Compliant soldering ensures your circuits last longer, perform better, and don’t pose risks like electrical shorts or fires. Plus, if you ever transition to professional work or share your projects, having a foundation in standardized practices gives you credibility.

For instance, a poorly soldered joint might work initially but fail under stress, causing a device to malfunction. IEC standards help you avoid such issues by providing a framework for durability—think of a joint that withstands vibrations or temperature changes because it was soldered correctly.

Conclusion: Start Soldering with Confidence

Soldering is a fundamental skill for any electronic hobbyist, and aligning with IEC standards elevates your work from amateur to professional-grade. By following this simple IEC soldering guide, using the right tools, and practicing soldering techniques for hobbyists, you can create safe, reliable projects that stand the test of time.

Remember the basics: prepare your workspace, use quality materials, apply heat properly, and inspect your joints. With these steps, you’ll master IEC soldering for beginners and build a strong foundation for more advanced electronics work. Start small, stay safe, and keep learning—your soldering skills will improve with every project.

ALLPCB

ALLPCB