Introduction

Selecting the right pressure sensor is critical to system performance and stability for electronics engineers. This article reviews the Amphenol All Sensors BFTM series basic pressure sensors, highlighting their key features and advantages.

Product Overview

The BFTM series uses the company's proprietary technology to deliver high performance in a minimized footprint. Compared with traditional silicon sensors, it significantly reduces output offset errors caused by position sensitivity, package-induced stress, and long-term drift. Its silicon micromechanical stress-concentrating enhanced structure provides highly linear pressure measurement output.

The series is intended for noncorrosive, nonionic working fluids such as air and dry gases. It provides a ratiometric output proportional to the supply voltage, ensuring high accuracy and reliability in demanding applications. With a compact design and improved precision, the BFTM basic pressure sensors are suitable for industrial and environmental monitoring applications that require reliable pressure measurement.

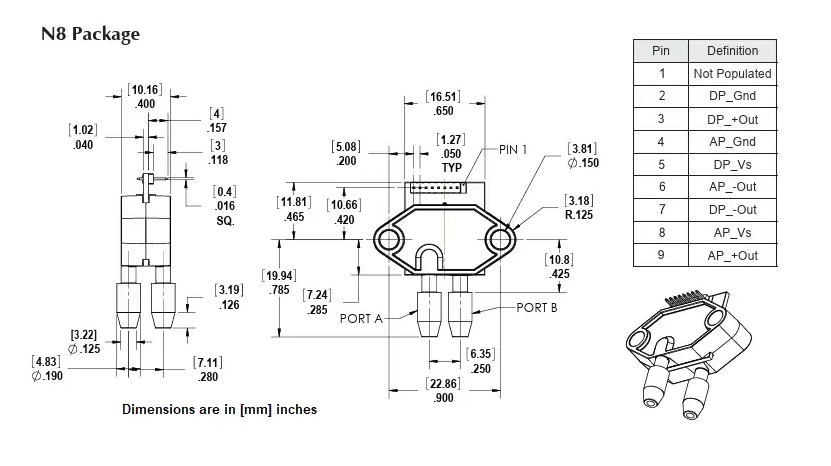

Package Drawing

Key Features

1. Compact, stable design

The compact design enables stable operation in limited spaces, giving engineers more flexibility during system design.

2. Enhanced accuracy

High measurement accuracy meets demanding application requirements for pressure sensing.

3. Optimized packaging

Suitable for high common-mode and low differential pressure monitoring, ensuring accurate measurement across varying pressure conditions.

4. Single-package absolute and differential measurement

One sensor supports both absolute and differential pressure measurement, reducing system complexity and cost.

5. RoHS compliant

Designed to meet modern electronic equipment environmental requirements.

Applications

HVAC

In heating, ventilation, and air conditioning systems, precise pressure measurement is essential for regulating airflow and temperature. The BFTM series provides reliable pressure data for these systems.

Industrial control

Accurate pressure control in industrial processes is critical for product quality and operational safety. The BFTM sensors meet various industrial pressure measurement needs.

Environmental control

Accurate pressure measurement supports atmospheric monitoring and environmental analysis. The BFTM series supplies precise pressure information for environmental control systems.

Mass flow controllers

Mass flow controllers require precise pressure measurements to regulate fluid flow. The BFTM sensors' high accuracy supports these requirements.

Gas mixers

Stable and accurate pressure measurement is essential for controlling gas mixture ratios. The BFTM series supports accurate gas mixing operations.

Performance Specifications

Maximum Ratings

- Supply voltage (VS): maximum 6 V DC.

- Pin temperature (solder 2 to 4 seconds): 270°C.

Environmental Specifications

- Temperature range: operating -25°C to 85°C, storage -40°C to 125°C.

- Humidity limits: 0 to 95% RH, non-condensing.

Standard Pressure Ranges

Different models vary in pressure range, operating pressure, single-port proof pressure, single-port burst pressure, and common-mode pressure. For example, model L02D-060A has an operating range of 0–60 PSIA (absolute pressure) and 0–2 inH2O (differential), single-port proof pressure of 100 inH2O, single-port burst pressure of 200 inH2O, and common-mode pressure of 250 PSI.

Performance Characteristics

Detailed parameters are specified for absolute and differential elements, including offset voltage, sensitivity, temperature effects on offset, temperature effects on resistance, temperature effects on span, linearity error, hysteresis error, input resistance, output resistance, and long-term stability. For example, the absolute element sensitivity at 60 PSIA is 1.92–3.42 mV/PSI.

Packaging and Connections

Package Pinout

The N8 package has defined pin assignments, such as pin 2 = DP Gnd and pin 3 = DP + Out, which provides clear guidance for circuit design.

Parylene Coating

Parylene coating provides moisture protection and helps shield the sensor from certain harsh media. Unlike some suppliers, All Sensors applies the Parylene coating in-house using an advanced production process to maintain precision and reliability. Note that this coating option is not available for sensors with a ±2 inH2O pressure range.

Recommended Accessories

Female mating connector

Harwin Inc. Part # M50-3030842 or equivalent.

Tubing

Parker Part # NB-4-062 or equivalent.

Manifold seal design

Specific design specifications are provided to ensure proper connection and sealing between the sensor and other components.

Summary

The Amphenol All Sensors BFTM series basic pressure sensors combine stable performance, compact form factor, and high-accuracy measurement capabilities, making them suitable for industrial control, environmental monitoring, and other demanding applications that require reliable pressure sensing.

ALLPCB

ALLPCB