The influence of artificial intelligence is widespread. Products are becoming more intelligent and can perform tasks previously done by humans. Complex tasks can be completed faster and more accurately, and failures can now be predicted more reliably and addressed before they occur. The AI technologies enabling this, and how they can be applied to additional tasks, are the subject of a recent white paper from Siemens Digital Industries Software. The white paper provides a comprehensive view of this changing landscape, relevant to electronic systems design. Below is an overview of Siemens Digital Industries' perspective on AI and its impact on system design.

AI tools in industry

The term artificial intelligence covers a broad range of meanings. It represents a set of algorithms and information-processing strategies. Many concepts have existed for a long time, some dating back to the 1940s. New combinations of application strategies supported by massive computing power have created the revolution we are witnessing. According to the white paper:

"In the past decade, artificial intelligence (AI) has evolved from a visionary concept into mainstream reality within many large companies."

The white paper outlines the technologies involved in this revolution and how they combine to address real-world problems. These technologies draw on mathematics, computer science, statistics, and psychology, and include machine learning and deep learning. The objectives of AI applications are broad, including:

- making informed decisions to improve efficiency;

- completing routine tasks with minimal effort to increase productivity;

- improving expertise by recommending the next task;

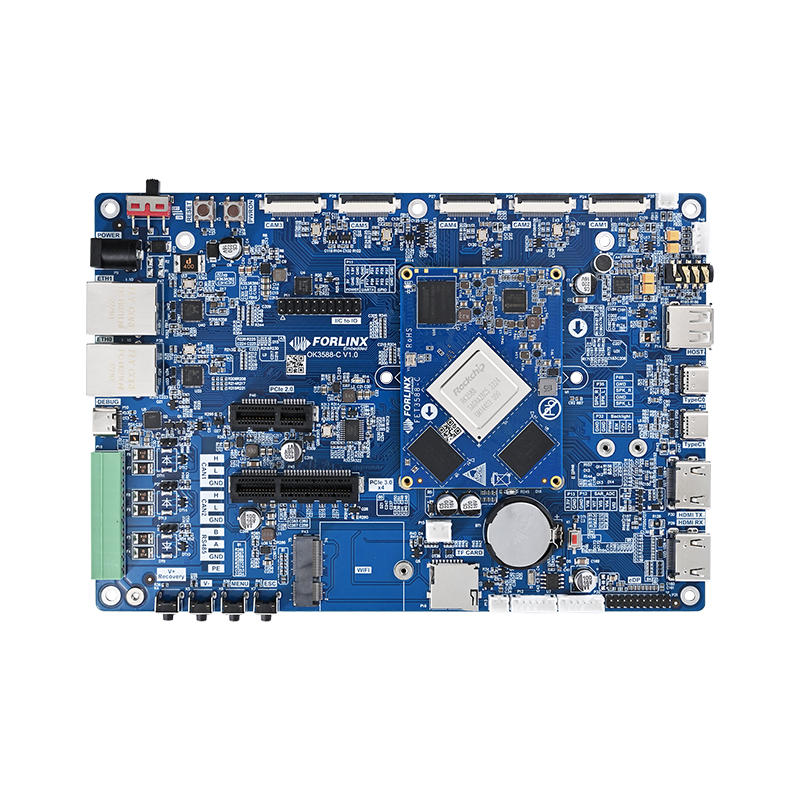

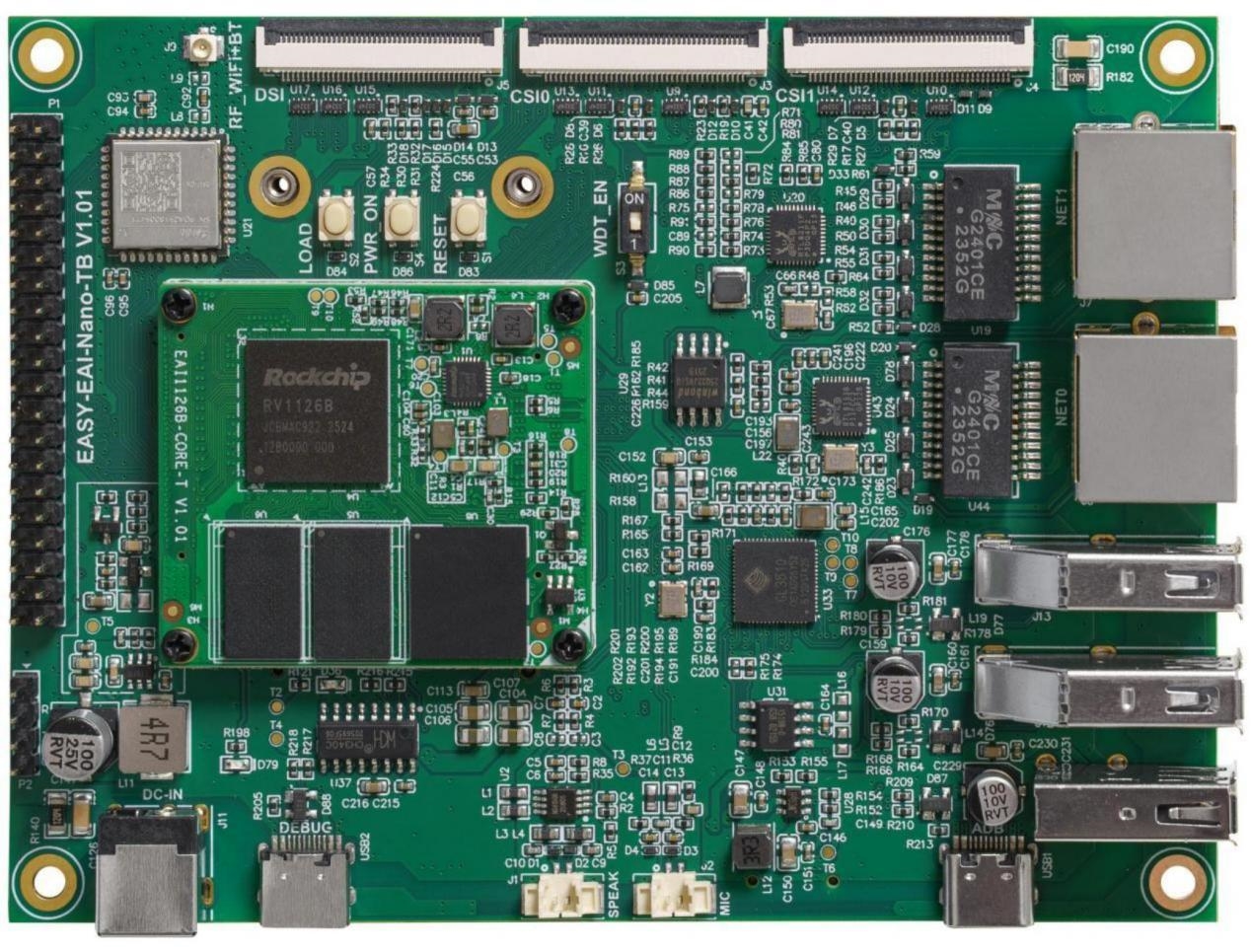

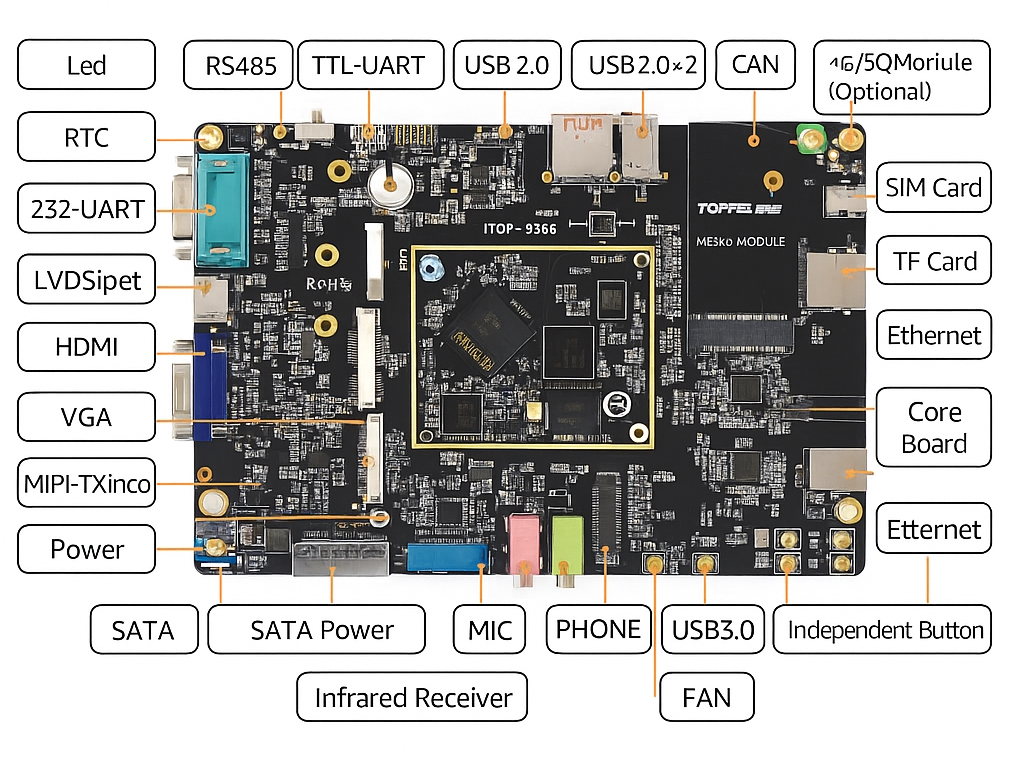

- applying AI in printed circuit board (PCB) design.

The white paper uses PCB design as an example to illustrate AI's impact. PCB design challenges engineers to provide adequate power and cooling for complex, high-speed ICs while maintaining signal and thermal integrity for each high-speed signal between ICs on the board. The problem complexity can escalate quickly. This example provides useful context for how AI can change various aspects of design.

The white paper discusses many impacts of AI on the design process. A short summary follows:

- Learning curve: Experienced engineers use intuition to choose the best tools and settings. This is a primary reason senior engineers are far more productive than junior engineers. What if AI could capture that intuition so junior engineers could perform at a higher level?

- Component selection: Engineers spend substantial time researching component choices to meet system requirements. What if a model based on historical data could significantly reduce selection time?

- Component model creation: Generating models to represent components (for example, symbols, 2D/3D physical geometry, and simulation models) is time consuming and requires diverse skills. Could natural language processing, image recognition, and machine learning be applied here?

- Schematic connectivity: Optimal component placement and connectivity require a broad design perspective. This is another area where AI could be applied.

- Dynamic reuse: Once a design is complete, knowledge applied to that design is often lost. What if that knowledge could be preserved and managed?

- Constraints: Prior knowledge can simplify tasks and yield higher-quality results.

- Layout: These tasks use heuristic methods to optimize automation. What if AI could make these methods more specific and accurate?

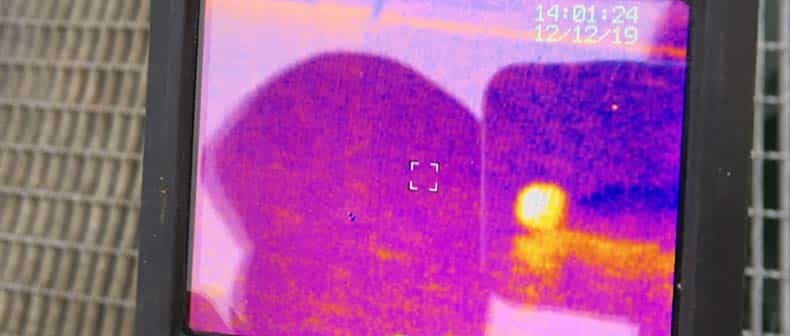

- Analysis and verification: Sensitivities to material properties, physical layout, and temperature/voltage make this process challenging. What if AI could distill interdependencies into a more predictable model?

- Design synthesis: Combining all of the above, generative AI methods will have substantial impact.

Big picture

Siemens Digital Industries Software operates across a broad range of markets, industries, and application areas. The white paper discusses investments in deploying AI across this spectrum.

Examples discussed include:

- AI/ML-based edge application accelerators to shorten time to market;

- optimization of decoupling capacitor banks in power transmission grids using genetic algorithms;

- an adaptive user interface that improves efficiency by predicting the commands a user is most likely to use;

- next-step recommendation accuracy of 90% in microfluidics.

These examples cover design, manufacturing, and production. As part of the Siemens Xcelerator portfolio, they illustrate AI applications across electronic systems design.

ALLPCB

ALLPCB