If you're looking to boost the performance of your single-sided PCB design, choosing the right substrate material is key. Advanced substrate materials can enhance signal integrity, improve thermal management, and ensure reliability in high-performance applications. In this blog, we’ll dive deep into the world of substrate options for single-sided PCBs, exploring how they can elevate your designs and offering practical insights to help you make informed decisions.

What Are Single-Sided PCBs and Why Do Substrate Materials Matter?

Single-sided printed circuit boards (PCBs) are the simplest type of PCB, featuring conductive traces on only one side of the board. They are widely used in low-cost, less complex electronic devices like calculators, LED lighting, and basic sensors. Despite their simplicity, the performance of single-sided PCBs heavily depends on the substrate material—the insulating layer that supports the copper traces.

The substrate material affects several critical factors, including electrical performance, heat dissipation, and durability. With the growing demand for compact, high-performance electronics, traditional materials may fall short. That’s where advanced substrate options come in, offering enhanced properties to meet modern design challenges.

The Role of Substrate Materials in PCB Design

In PCB design, the substrate acts as the foundation. It provides mechanical support and electrical insulation between conductive layers. For single-sided PCBs, where space and cost are often constraints, the substrate must balance performance with affordability. Here’s how substrate materials impact key aspects of PCB performance:

- Signal Integrity: The dielectric constant (Dk) of a substrate determines how fast electrical signals travel through the board. A lower Dk value means faster signal speeds, which is critical for high-frequency applications.

- Thermal Management: Heat dissipation is vital to prevent component failure. Substrates with high thermal conductivity help transfer heat away from critical areas.

- Mechanical Strength: The substrate must withstand physical stress during manufacturing and operation without cracking or warping.

- Cost Efficiency: For single-sided PCBs often used in budget-friendly designs, the substrate should offer a good balance between performance and price.

Understanding these factors helps designers select the right material for enhancing single-sided PCB performance, especially in high-performance applications.

Common Substrate Materials for Single-Sided PCBs

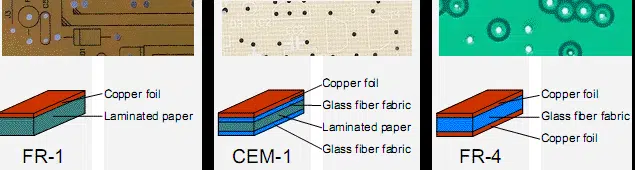

Before diving into advanced options, let’s review the standard substrate materials typically used in single-sided PCB design:

- FR-4: The most common substrate, made of woven fiberglass and epoxy resin. It offers decent electrical insulation with a dielectric constant of around 4.5 and is cost-effective for general-purpose applications. However, it struggles with high-frequency signals and extreme thermal conditions.

- CEM-1: A composite material made of paper and epoxy, often used in low-cost single-sided PCBs. It’s less durable than FR-4 and not suitable for demanding environments.

- Phenolic Paper: An older, cheaper option made from paper and phenolic resin. It’s lightweight but lacks the strength and thermal resistance needed for modern designs.

While these materials work well for basic applications, they often fall short in high-performance scenarios where signal speed, heat dissipation, and reliability are critical.

Advanced Substrate Options for High-Performance Single-Sided PCBs

To meet the demands of modern electronics, advanced substrate materials have been developed. These options offer superior properties for enhancing single-sided PCB performance. Let’s explore some of the top choices:

1. High-Frequency Laminates

High-frequency laminates are designed for applications where signal integrity is paramount, such as in RF (radio frequency) and microwave circuits. These materials have a lower dielectric constant (often between 2.2 and 3.5) and lower loss tangent, reducing signal loss at high frequencies.

For single-sided PCBs used in communication devices or IoT modules, high-frequency laminates ensure faster signal transmission and minimal interference. They are more expensive than standard FR-4 but are worth the investment for performance-critical designs.

2. Polyimide Substrates

Polyimide substrates are known for their excellent thermal stability and flexibility. They can withstand temperatures up to 260°C without degrading, making them ideal for single-sided PCBs in harsh environments like automotive or aerospace applications.

Additionally, polyimide’s flexibility allows for lightweight, bendable designs, which are useful in compact electronics. While the cost is higher than traditional materials, the durability and heat resistance make it a strong choice for high-performance needs.

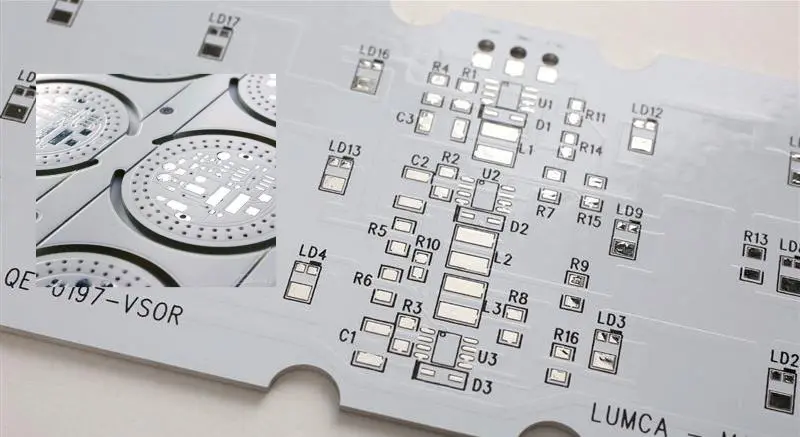

3. Metal-Core Substrates (MCPCB)

Metal-core PCBs use a metal base, often aluminum or copper, as the substrate to improve heat dissipation. For single-sided designs in high-power applications like LED lighting or power supplies, metal-core substrates can transfer heat away from components, extending their lifespan.

The thermal conductivity of aluminum, for example, is around 200 W/m·K, far superior to FR-4’s 0.3 W/m·K. This makes metal-core substrates a go-to option for thermal management in single-sided PCBs.

4. Ceramic Substrates

Ceramic substrates, such as alumina or aluminum nitride, offer exceptional thermal conductivity and electrical insulation. With thermal conductivity values ranging from 20 to 170 W/m·K, they are perfect for high-power, high-temperature applications.

Though ceramics are more expensive and harder to process, they provide unmatched reliability for single-sided PCBs in industrial or medical devices where performance cannot be compromised.

Benefits of Using Advanced Substrate Materials

Switching to advanced substrate materials offers several advantages for enhancing single-sided PCB performance. Here are the key benefits:

- Improved Signal Integrity: Materials with lower dielectric constants and loss tangents ensure cleaner, faster signals, reducing delays and noise in high-frequency designs.

- Better Thermal Management: High thermal conductivity materials prevent overheating, protecting components and improving reliability.

- Enhanced Durability: Advanced substrates resist environmental stressors like heat, humidity, and mechanical shock, extending the lifespan of the PCB.

- Compact Design Support: Lightweight and flexible materials allow for smaller, more innovative designs without sacrificing performance.

These benefits make advanced substrates a smart choice for engineers working on cutting-edge electronics, even in the simpler realm of single-sided PCB design.

How to Choose the Right Substrate for Your Single-Sided PCB

Selecting the best substrate material for your single-sided PCB depends on your project’s specific needs. Here are some practical steps to guide your decision:

- Define Application Requirements: Consider the operating environment. Will the PCB face high temperatures, humidity, or mechanical stress? For harsh conditions, opt for polyimide or ceramic substrates.

- Evaluate Electrical Needs: If your design involves high-frequency signals, prioritize materials with low dielectric constants, such as high-frequency laminates.

- Assess Thermal Demands: For high-power applications, choose substrates with high thermal conductivity, like metal-core or ceramic options.

- Balance Cost and Performance: While advanced materials improve performance, they come at a higher price. Weigh the benefits against your budget to find the best fit.

By carefully analyzing these factors, you can select a substrate that enhances your single-sided PCB’s performance without unnecessary costs.

Future Trends in Substrate Materials for PCB Design

The field of PCB substrate materials is evolving rapidly, driven by the demand for smaller, faster, and more efficient electronics. Here are some emerging trends to watch:

- Sustainable Materials: Eco-friendly substrates made from biodegradable or recyclable materials, such as lignocellulose nanofibrils, are gaining attention for reducing the environmental impact of electronics.

- Nanotechnology Integration: Substrates embedded with nanomaterials are being developed to improve electrical and thermal properties at a microscopic level.

- Hybrid Substrates: Combining different materials, like metal and polymer layers, offers tailored solutions for specific performance needs.

Staying updated on these trends can help you future-proof your single-sided PCB designs and maintain a competitive edge in the industry.

Practical Tips for Implementing Advanced Substrates in Your Design

Once you’ve chosen an advanced substrate material, proper implementation is crucial for maximizing performance. Here are some actionable tips:

- Work with Experienced Manufacturers: Advanced materials often require specialized processing. Partner with a reliable fabrication team to ensure quality.

- Test Prototypes Thoroughly: Before full-scale production, create prototypes to test signal integrity, thermal performance, and durability under real-world conditions.

- Optimize Layout Design: Adjust trace widths and spacing to match the electrical properties of the substrate, minimizing signal loss and interference.

- Monitor Material Compatibility: Ensure that the chosen substrate works well with other components and soldering processes to avoid issues during assembly.

Following these steps can help you seamlessly integrate advanced substrates into your single-sided PCB projects.

Conclusion: Elevate Your Single-Sided PCB with Advanced Substrates

Advanced substrate materials are transforming the capabilities of single-sided PCBs, making them suitable for high-performance applications despite their simplicity. From high-frequency laminates to metal-core and ceramic options, these substrates offer improved signal integrity, thermal management, and durability. By carefully selecting the right material for your design needs and following best practices during implementation, you can significantly enhance the performance of your single-sided PCBs.

Whether you’re working on LED lighting, IoT devices, or industrial electronics, exploring substrate options is a step toward innovation. Stay informed about emerging materials and trends to keep your designs at the forefront of technology. With the right substrate, even the simplest PCB can deliver exceptional results.

ALLPCB

ALLPCB