Overview

Subtle changes in the sounds produced by equipment during routine operation often contain early signals of potential faults. Adaptive-filter acoustic sensors dynamically capture and analyze acoustic signature features to provide more accurate early warnings for the stable operation of power systems, and they serve as technical support for safe operation and maintenance of distribution rooms.

Adaptive Filtering Principle

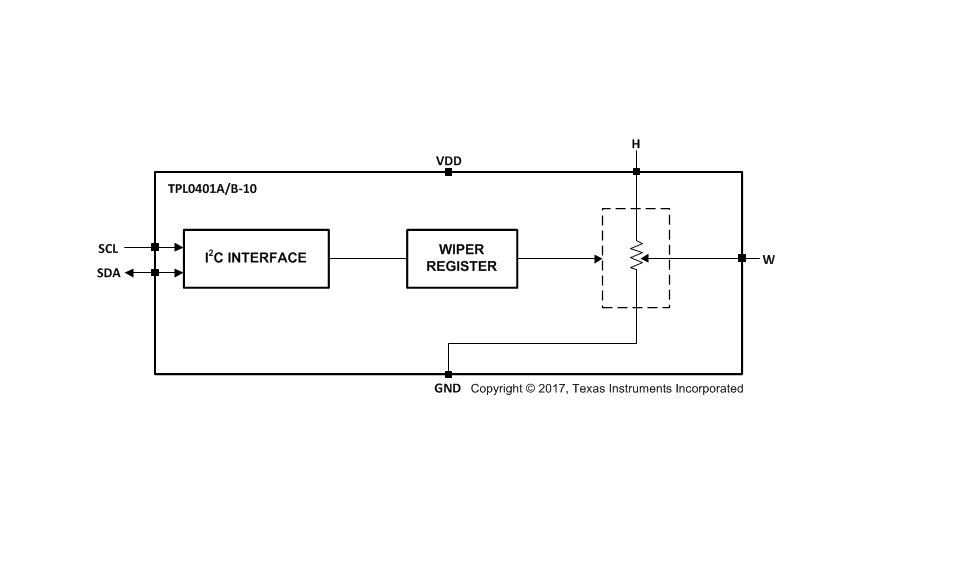

The core of adaptive filtering technology is its dynamic adaptation capability. Conventional acoustic monitoring devices are vulnerable to interference in complex noise environments, while adaptive-filter acoustic sensors can analyze environmental noise characteristics in real time and adjust filtering parameters dynamically to suppress background noise and highlight anomalous acoustic signals from equipment. This noise-reduction capability enables the sensors to maintain high sensitivity in multi-device, high-noise distribution room scenarios, reducing missed detections and false alarms.

Feature Extraction and Fault Detection

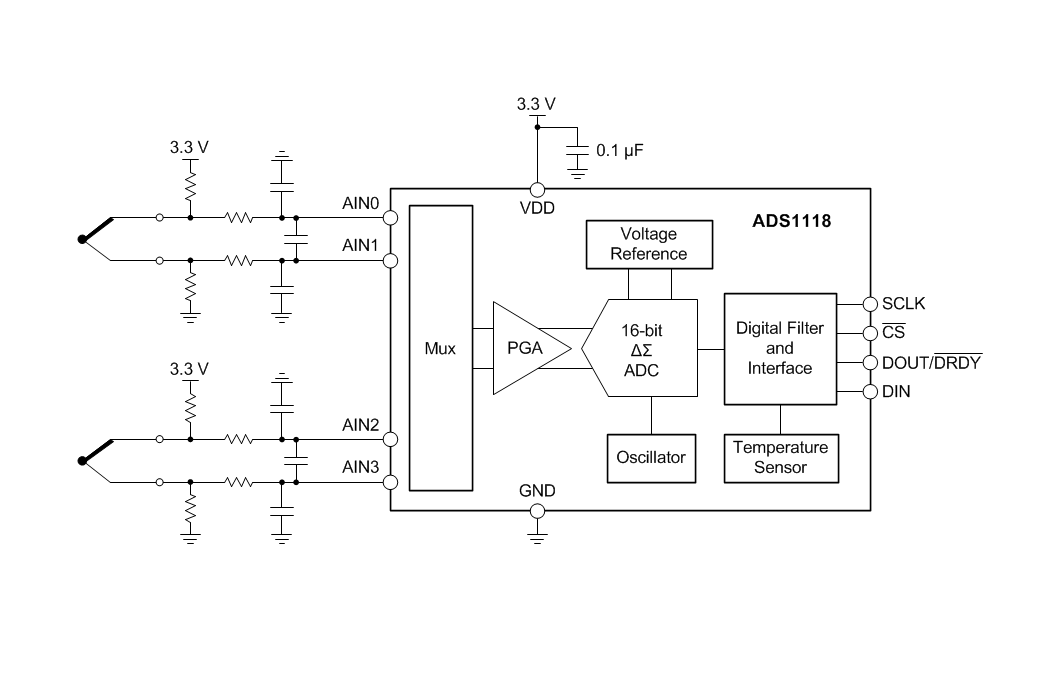

The sensor's technical strengths lie in multi-dimensional acoustic feature extraction and analysis. By collecting parameters such as frequency, amplitude, and waveform of operating sound waves and combining them with adaptive filtering algorithms, the device can perform multi-dimensional quantitative assessments of operating status. For example, when a transformer experiences partial discharge, its acoustic signature shows anomalous fluctuations at specific frequencies. The sensor can identify such potential faults in advance by analyzing these feature changes in real time, giving maintenance personnel more time to respond.

Application and Operational Benefits

Adaptive-filter acoustic sensors improve the automation level of distribution room maintenance. Their non-intrusive installation reduces retrofit difficulty, while remote data transmission and automated diagnostics enable new maintenance workflows. Operators can view acoustic data remotely and use historical trend analysis to pinpoint fault warnings and predict trends, shifting maintenance from reactive responses toward preventive measures.

Trends and Integration

With the deeper integration of artificial intelligence and the Internet of Things, adaptive-filter acoustic sensors are evolving toward higher intelligence and greater integration. Fusing data from temperature, vibration, and other sensors with machine learning algorithms enables more comprehensive equipment health assessment models. At the same time, applying edge computing improves data processing efficiency, enabling real-time analysis of acoustic data and faster responses, which strengthens technical support for safe operation of distribution rooms.

Summary

Given growing demands for electrical safety, adaptive-filter acoustic sensors provide a scientific and reliable method for intelligent monitoring in distribution rooms. They support stable equipment operation and contribute to transforming power maintenance practices toward more proactive, data-driven approaches.

ALLPCB

ALLPCB