If you're diving into PCB assembly, you might be wondering what a solder reflow oven is and why it’s essential. Simply put, a solder reflow oven is a specialized machine used to solder surface mount components onto printed circuit boards (PCBs) by heating solder paste until it melts and forms strong connections. This guide will walk you through everything you need to know about solder reflow ovens, from how they work to choosing the right one for your needs. Whether you're a hobbyist or a professional in electronics manufacturing, this detailed resource will help you master the reflow process.

What Is a Solder Reflow Oven?

A solder reflow oven is a critical tool in modern electronics assembly, especially for surface mount technology (SMT). It works by heating a PCB with pre-applied solder paste and components to a specific temperature, causing the solder to melt or "reflow" and create permanent electrical connections. This process is highly efficient compared to manual soldering, particularly for tiny components that are hard to handle by hand.

Reflow ovens come in various sizes and configurations, from small desktop units for hobbyists to large industrial systems with conveyor belts for high-volume production. Regardless of the type, the goal remains the same: to achieve consistent, reliable soldering with minimal defects.

Why Use Solder Reflow Ovens in PCB Assembly?

Solder reflow ovens are the backbone of SMT assembly for several reasons. First, they provide uniform heating, which ensures that all components on a PCB are soldered evenly. This reduces the risk of cold solder joints or overheating, both of which can lead to failures. Second, reflow ovens are much faster than hand soldering, making them ideal for batch production or large-scale manufacturing.

Additionally, reflow ovens can handle complex boards with hundreds or thousands of components, something nearly impossible to achieve manually. For instance, modern smartphones and laptops rely on densely packed PCBs that require precise soldering—something only a reflow oven can deliver consistently.

How Does a Solder Reflow Oven Work?

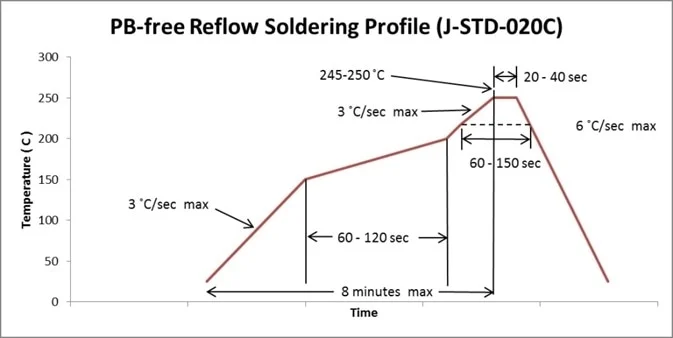

The reflow soldering process follows a controlled temperature profile divided into several stages. Understanding these stages is key to achieving optimal results with your reflow oven. Here's a breakdown of the process:

- Preheat Stage: The PCB is gradually heated to activate the flux in the solder paste and remove moisture. This stage typically ranges from 100°C to 150°C and lasts about 60-90 seconds.

- Soak Stage: The temperature stabilizes to ensure even heating across the board. This usually happens between 150°C and 200°C for another 60-120 seconds, allowing the components and PCB to reach thermal equilibrium.

- Reflow Stage: The oven reaches its peak temperature, often around 220°C to 250°C for lead-free solder, causing the solder paste to melt and form joints. This stage lasts only 20-40 seconds to avoid damaging components.

- Cooling Stage: The PCB cools down slowly to solidify the solder joints without thermal shock. The cooling rate is typically controlled at 2-4°C per second.

Most reflow ovens use either convection heating (hot air circulation) or infrared heating to achieve these temperature profiles. Industrial ovens often feature multiple zones, each set to a specific temperature, through which the PCB travels on a conveyor belt.

Types of Solder Reflow Ovens

Reflow ovens vary widely in design and capability, depending on the intended use. Here are the main types you’ll encounter:

1. Benchtop Reflow Ovens

These compact ovens are perfect for small-scale projects, prototyping, or hobbyists. They typically have a single heating chamber and can handle one or two PCBs at a time. Benchtop ovens are affordable, with prices starting around $200, but they lack the precision and capacity of larger systems.

2. Conveyor Reflow Ovens

Used in professional and industrial settings, conveyor reflow ovens feature a long tunnel with multiple heating zones. PCBs move through the oven on a conveyor belt, passing through preheat, soak, reflow, and cooling zones. These ovens are ideal for high-volume production, processing dozens or hundreds of boards per hour.

3. Vapor Phase Reflow Ovens

This advanced type uses a liquid medium (often a fluorinated fluid) that turns into vapor when heated. The vapor condenses on the PCB, providing extremely uniform heating. Vapor phase ovens are excellent for complex assemblies but are more expensive and less common than convection or infrared ovens.

Key Features to Look for in a Solder Reflow Oven

Choosing the right reflow oven depends on your specific needs, budget, and production volume. Here are some critical features to consider:

- Temperature Control: Look for ovens with precise temperature regulation, ideally within ±1°C, to ensure consistent soldering results.

- Heating Zones: For larger ovens, multiple heating zones (4-10 zones) allow better control over the temperature profile, reducing defects.

- Conveyor Speed: Adjustable conveyor speed is essential for industrial ovens to match the reflow profile to different PCB designs.

- Size and Capacity: Ensure the oven can accommodate your PCB dimensions and production volume. For example, a small benchtop oven might handle PCBs up to 200mm x 200mm, while industrial models can process much larger boards.

- Cooling System: Effective cooling prevents thermal stress on components. Some ovens include forced air cooling for faster and safer cooldowns.

Best Practices for Using Solder Reflow Ovens

To get the most out of your reflow oven and ensure high-quality PCB assembly, follow these best practices:

1. Optimize Your Temperature Profile

Every PCB and solder paste combination requires a unique temperature profile. Refer to the solder paste manufacturer’s datasheet for recommended settings. For lead-free solder, peak temperatures often range from 235°C to 250°C, while leaded solder might require 210°C to 230°C. Use a thermocouple or profiling tool to measure the actual temperature on your PCB and adjust the oven settings accordingly.

2. Use High-Quality Solder Paste

The solder paste you choose directly impacts the reflow process. Ensure it matches your components and PCB materials. For example, lead-free solder paste typically has a higher melting point (around 217°C) compared to leaded paste (around 183°C), requiring different reflow profiles.

3. Maintain Proper Component Placement

Before placing the PCB in the oven, double-check that all components are correctly aligned on the solder paste. Misaligned components can lead to poor connections or tombstoning (when a component stands up on one end during reflow).

4. Regular Oven Maintenance

Clean the oven regularly to remove flux residue and debris, which can affect heating efficiency. Check the conveyor belt (if applicable) for wear and ensure heating elements are functioning properly. A well-maintained oven can last for years without performance issues.

Common Challenges in Reflow Soldering and How to Solve Them

Even with the best equipment, reflow soldering can present challenges. Here are some common issues and their solutions:

1. Cold Solder Joints

Cold solder joints occur when the solder doesn’t fully melt, leading to weak connections. This is often due to insufficient peak temperature or a short reflow time. Increase the oven’s peak temperature by 5-10°C or extend the reflow stage duration slightly.

2. Tombstoning

Tombstoning happens when a component lifts on one side during reflow, resembling a tombstone. It’s usually caused by uneven heating or improper solder paste application. Ensure the preheat stage is long enough (at least 60 seconds) to balance thermal distribution across the board.

3. Solder Bridging

This defect occurs when excess solder connects adjacent pads, creating short circuits. It can result from too much solder paste or incorrect reflow temperatures. Reduce the amount of paste applied during stencil printing and verify that the reflow profile matches the paste’s specifications.

Benefits of Using Solder Reflow Ovens for PCB Assembly

Investing in a solder reflow oven offers numerous advantages for anyone involved in PCB assembly:

- Consistency: Automated temperature control ensures every board is soldered under the same conditions, minimizing human error.

- Speed: Reflow ovens can process multiple boards simultaneously, drastically reducing assembly time compared to manual soldering.

- Quality: Precise heating profiles reduce defects, leading to higher reliability in finished products. For example, well-soldered joints can withstand mechanical stress and thermal cycling better.

- Scalability: From small desktop units to industrial systems, reflow ovens can scale with your production needs, supporting both prototyping and mass production.

Choosing the Right Solder Reflow Oven for Your Needs

Selecting a reflow oven depends on several factors, including your budget, production volume, and the complexity of your PCBs. Here’s a quick guide to help you decide:

- Hobbyists or Small Businesses: A benchtop reflow oven costing $200-$1,000 is sufficient for low-volume work or prototyping. Look for models with digital temperature controls for better accuracy.

- Medium-Scale Production: If you’re assembling hundreds of boards per month, consider a mid-range conveyor oven with 4-6 heating zones, priced between $5,000 and $20,000.

- High-Volume Manufacturing: For large-scale operations, invest in an industrial conveyor oven with 8-10 zones and advanced features like nitrogen atmosphere soldering. These systems can cost $30,000 or more but are built for continuous operation.

Conclusion: Mastering Solder Reflow for Better PCB Assembly

Solder reflow ovens are indispensable tools for anyone involved in PCB assembly, offering precision, speed, and reliability that manual soldering simply can’t match. By understanding how these ovens work, selecting the right model for your needs, and following best practices, you can achieve high-quality soldering results with minimal defects. Whether you’re assembling a single prototype or running a full production line, mastering the use of a reflow oven will elevate your electronics manufacturing process.

At ALLPCB, we’re committed to supporting your PCB assembly journey with expert resources and top-notch services. Dive into the world of solder reflow ovens and take your projects to the next level with confidence.

ALLPCB

ALLPCB