If you're looking for comprehensive information on designing and manufacturing PCBs for water treatment control systems, you've come to the right place. This guide covers everything you need to know about water treatment PCB design guidelines, PCB material selection for water, PCB manufacturing process for water treatment, PCB assembly for water control, and PCB reliability in water systems. Whether you're an engineer or a project manager, you'll find actionable insights to ensure your PCBs perform optimally in challenging water treatment environments.

In the following sections, we'll dive deep into each aspect of PCB development for water control systems, providing practical tips, technical details, and best practices to help you achieve reliable and efficient results.

Why Water Treatment Control PCBs Are Critical

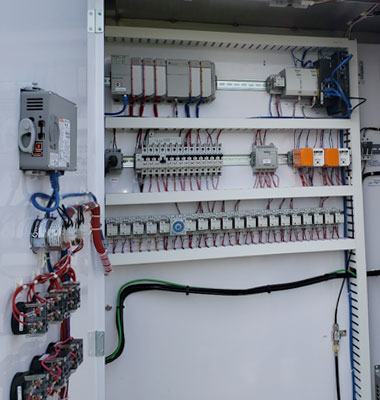

Water treatment systems are essential for ensuring clean and safe water in industrial, municipal, and residential settings. These systems rely heavily on electronic controls to monitor and manage processes like filtration, chemical dosing, and flow regulation. At the heart of these controls are printed circuit boards (PCBs) that must withstand harsh conditions such as high humidity, temperature fluctuations, and exposure to corrosive substances.

Designing and manufacturing PCBs for water treatment requires specialized knowledge to ensure durability and performance. A poorly designed PCB can lead to system failures, costly downtime, and even safety hazards. That's why understanding the nuances of water treatment PCB design guidelines and material selection is so important.

Water Treatment PCB Design Guidelines

Designing a PCB for water treatment control systems starts with understanding the unique challenges of the environment. Here are key guidelines to follow for a robust and reliable design:

1. Account for Environmental Factors

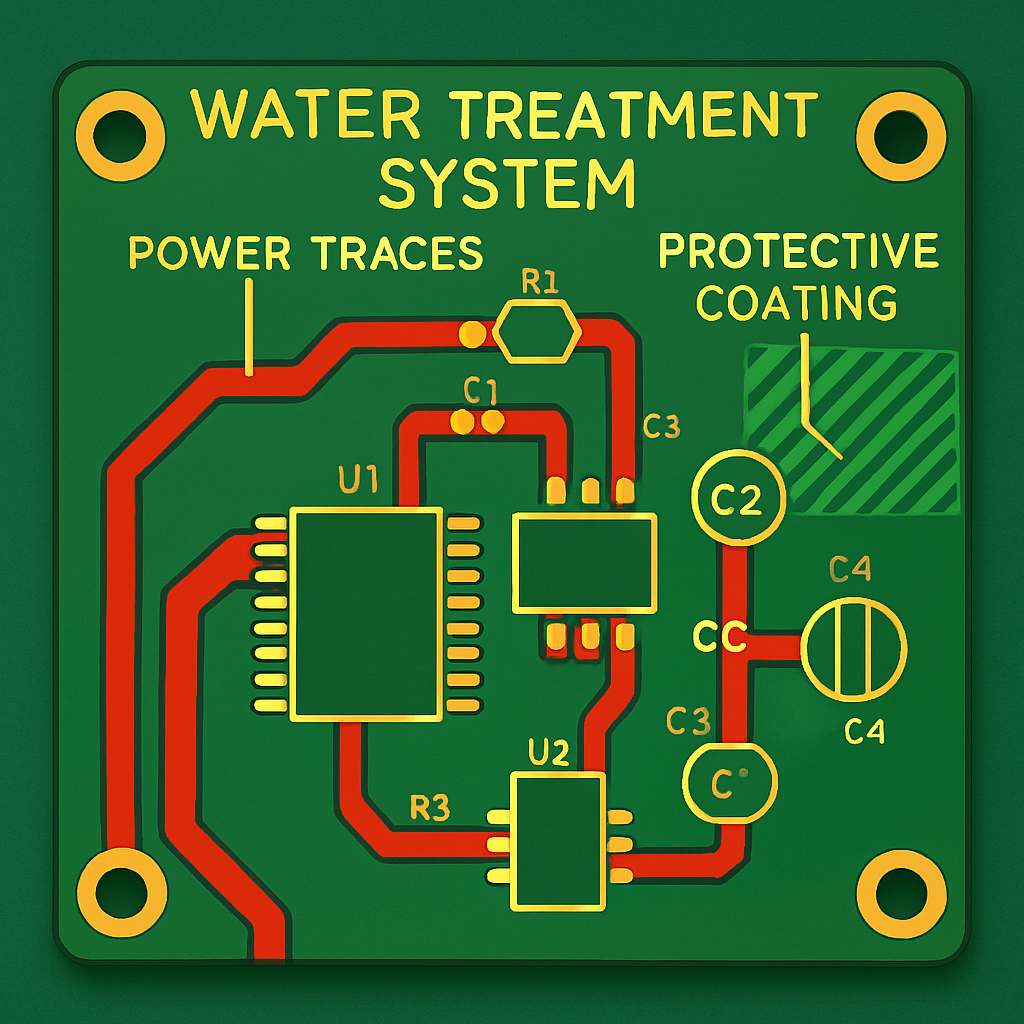

Water treatment systems often operate in high-humidity environments or areas with potential water exposure. Design your PCB with protective measures like conformal coatings to prevent moisture ingress. Additionally, consider temperature ranges—components should be rated for extremes, such as -40°C to 85°C, to handle outdoor or industrial settings.

2. Optimize Layout for Signal Integrity

In water control systems, sensors and actuators often send low-voltage signals that can be disrupted by noise. Keep signal traces short and away from high-power lines to minimize interference. Use ground planes to reduce electromagnetic interference (EMI), and maintain a trace impedance of around 50 ohms for high-speed signals if applicable.

3. Prioritize Power Management

Water treatment systems may require consistent power delivery for pumps and valves. Design your PCB with adequate power traces—wider traces (e.g., 20-30 mils for high-current paths) can handle currents up to 2-3 amps without overheating. Include overcurrent protection circuits to safeguard against faults.

4. Component Placement for Accessibility

Place critical components like microcontrollers and sensors in areas that are easy to access for maintenance. Avoid clustering heat-generating components together to prevent thermal stress, which can reduce the lifespan of the PCB in humid conditions.

PCB Material Selection for Water Environments

Choosing the right materials is crucial for ensuring PCB reliability in water systems. The materials must resist corrosion, moisture, and thermal stress while maintaining electrical performance. Here's what to consider for PCB material selection for water applications:

1. Substrate Materials

The most common substrate for water treatment PCBs is FR-4, a fiberglass-epoxy laminate. It offers a good balance of cost, durability, and electrical insulation. However, for extreme conditions, consider high-Tg (glass transition temperature) FR-4 variants with Tg values above 170°C to handle higher thermal loads. For even harsher environments, polyimide substrates can withstand temperatures up to 260°C and offer better moisture resistance.

2. Copper Thickness

Copper thickness affects current-carrying capacity and durability. For water treatment PCBs, use at least 1 oz/ft2 copper (approximately 35 microns thick) for standard applications. For high-power systems, opt for 2 oz/ft2 or higher to manage currents without excessive heat buildup.

3. Solder Mask and Surface Finish

A robust solder mask protects the PCB from moisture and contaminants. Liquid Photoimageable (LPI) solder masks are ideal for water treatment PCBs due to their uniform coverage. For surface finishes, Electroless Nickel Immersion Gold (ENIG) is a popular choice because it resists corrosion and provides excellent solderability, even after prolonged exposure to humid conditions.

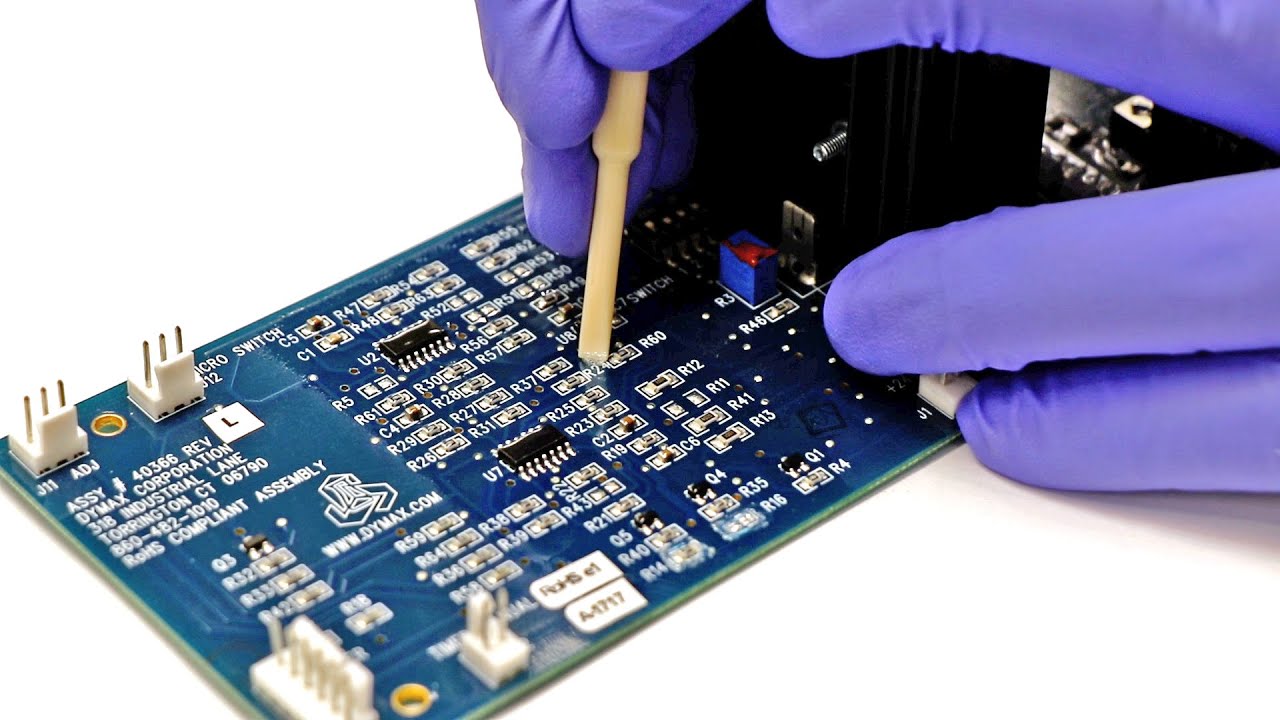

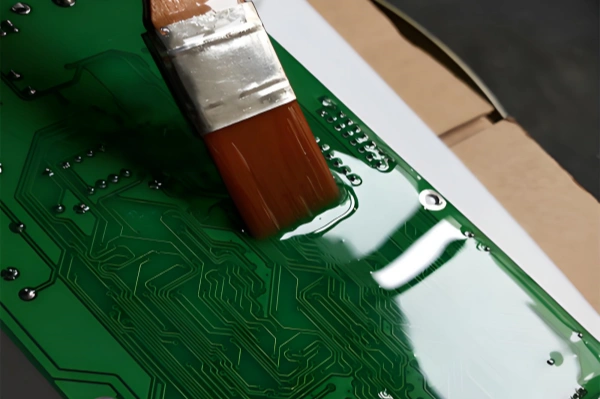

4. Conformal Coating

Applying a conformal coating is non-negotiable for PCBs in water systems. Silicone or acrylic coatings create a barrier against moisture and dust, extending the board's lifespan. Ensure the coating is evenly applied with a thickness of 25-75 microns for optimal protection.

PCB Manufacturing Process for Water Treatment

The PCB manufacturing process for water treatment systems must adhere to strict quality standards to ensure reliability. Here's an overview of the key steps involved:

1. Design File Preparation

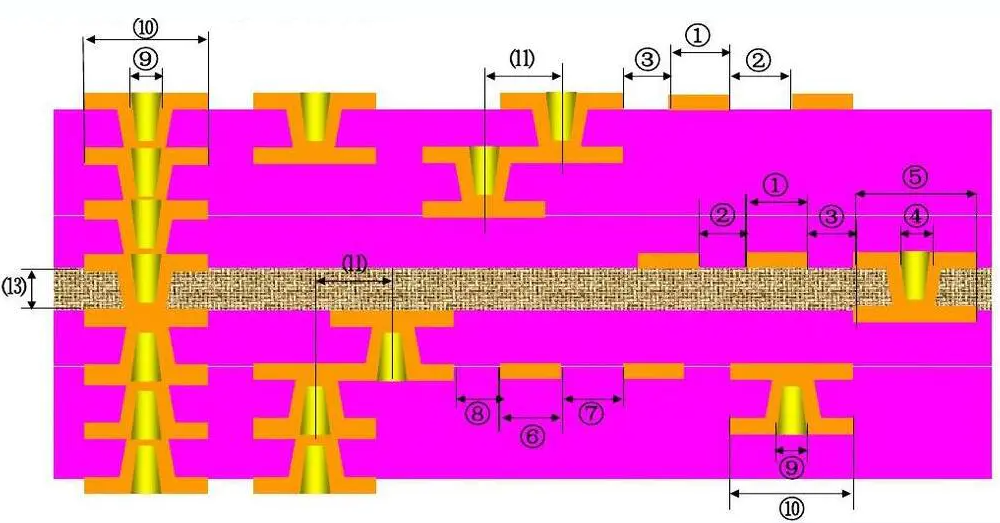

The process begins with converting design files into manufacturing data. Ensure that all design rules are followed, such as minimum trace widths (e.g., 6 mils for standard designs) and spacing to prevent short circuits. Double-check for proper layer stack-up, especially if using multilayer boards for complex water control systems.

2. Material Cutting and Drilling

Once the substrate material is selected, it's cut into panels and drilled for vias and mounting holes. Precision drilling is critical to avoid misalignment, which can affect component placement and signal integrity in water treatment applications.

3. Copper Etching and Plating

Copper layers are etched to form the circuit pattern, followed by plating to ensure strong connections through vias. For water treatment PCBs, additional plating thickness (e.g., 25-30 microns) can enhance durability against corrosion.

4. Solder Mask and Silkscreen Application

The solder mask is applied to protect the copper traces, and a silkscreen layer is added for component labeling. Ensure the solder mask covers all exposed areas to prevent moisture-related damage during operation in water systems.

5. Testing and Quality Control

Before shipping, PCBs undergo rigorous testing, including electrical continuity tests and automated optical inspection (AOI). For water treatment applications, consider environmental stress testing to simulate humidity and temperature extremes, ensuring PCB reliability in water systems.

PCB Assembly for Water Control Systems

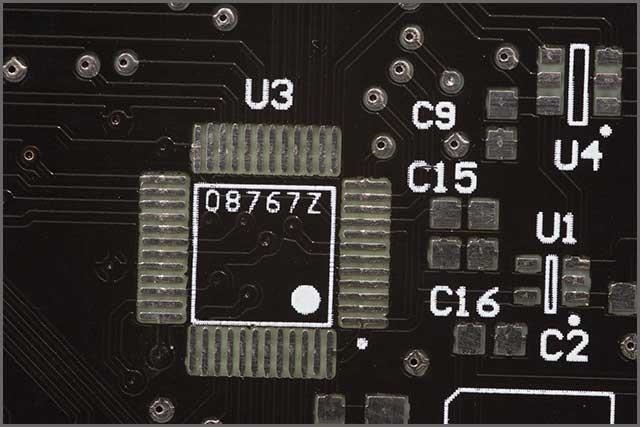

The PCB assembly for water control systems is just as important as design and manufacturing. Proper assembly ensures that components are securely placed and can withstand the operational demands of water treatment environments.

1. Component Selection

Choose components rated for industrial use with wide operating temperature ranges (e.g., -40°C to 105°C for capacitors and resistors). Opt for moisture-resistant components, such as sealed IC packages, to prevent failures in humid conditions.

2. Surface Mount Technology (SMT) vs. Through-Hole

Surface Mount Technology (SMT) is often preferred for water treatment PCBs due to its compact size and automated assembly capabilities. However, through-hole components may be used for high-power connectors or relays that require extra mechanical strength.

3. Soldering Techniques

Use lead-free solder compliant with RoHS standards to ensure environmental safety, especially in water treatment applications. Maintain soldering temperatures between 260°C and 300°C to avoid damaging components or substrates.

4. Post-Assembly Protection

After assembly, apply a conformal coating to protect against moisture and dust. Additionally, consider potting or encapsulation for extra protection if the PCB will be exposed to direct water splashes or submersion.

Ensuring PCB Reliability in Water Systems

PCB reliability in water systems is the ultimate goal of the design and manufacturing process. Here are strategies to maximize longevity and performance:

1. Rigorous Testing Protocols

Conduct environmental testing, including thermal cycling and humidity exposure (e.g., 85% relative humidity at 85°C for 1000 hours), to validate the PCB's durability. Electrical testing should confirm signal integrity and power delivery under load.

2. Redundancy and Fail-Safes

Design redundancy into critical systems, such as dual power supplies or backup control circuits, to prevent total system failure. Include fail-safe mechanisms to shut down operations if a fault is detected.

3. Regular Maintenance

Even with robust designs, regular inspection and maintenance are necessary. Check for signs of corrosion or coating degradation, and replace components before they fail to avoid unexpected downtime.

4. Compliance with Standards

Ensure your PCBs meet industry standards like IPC-A-610 for assembly and IPC-6012 for manufacturing. Compliance with environmental standards, such as IP65 or IP67 ratings for water and dust resistance, is also critical for water treatment applications.

Conclusion: Building Reliable PCBs for Water Treatment

Creating PCBs for water treatment control systems is a complex but rewarding process. By following water treatment PCB design guidelines, carefully considering PCB material selection for water, optimizing the PCB manufacturing process for water treatment, ensuring precise PCB assembly for water control, and focusing on PCB reliability in water systems, you can build boards that perform consistently in challenging conditions.

At ALLPCB, we're committed to supporting engineers and manufacturers in developing high-quality PCBs tailored to specific applications like water treatment. With attention to detail and adherence to best practices, you can achieve durable, efficient, and reliable solutions for your water control systems.

ALLPCB

ALLPCB