In today’s fast-paced, tech-driven world, hotel room control systems are becoming smarter and more connected. From lighting and HVAC to door locks and entertainment systems, these systems rely on printed circuit boards (PCBs) to function seamlessly. But as technology evolves, so do the challenges of maintaining and updating these systems. Over-The-Air (OTA) updates offer a powerful solution for remotely updating firmware on hotel room control PCBs, ensuring they remain secure, efficient, and up-to-date without the need for physical intervention. In this blog, we’ll explore how to implement OTA updates effectively, diving into firmware update strategies, secure bootloaders, remote programming, wireless communication protocols, and update rollback mechanisms.

Why OTA Updates Matter for Hotel Room Control PCBs

Hotel room control systems manage critical functions that directly impact guest experience and operational efficiency. A single outdated or buggy firmware can lead to malfunctioning systems, security vulnerabilities, or dissatisfied guests. Traditionally, updating firmware required technicians to manually access each device, which is time-consuming and costly, especially in large hotels with hundreds of rooms. OTA updates solve this by enabling remote programming, allowing hotel management to deploy fixes, patches, and new features across all devices simultaneously.

Beyond convenience, OTA updates enhance security by addressing vulnerabilities as soon as they’re discovered. They also reduce downtime, as updates can be scheduled during off-peak hours. For PCB designers and hotel tech managers, implementing OTA updates is no longer optional—it’s a necessity for staying competitive in the hospitality industry.

Key Components of OTA Updates for Hotel Room Control PCBs

Implementing OTA updates on hotel room control PCBs involves several critical components. Each plays a vital role in ensuring updates are secure, reliable, and efficient. Let’s break down the essentials.

1. Firmware Update Strategies

Firmware update strategies define how updates are deployed and managed. For hotel room control PCBs, a robust strategy is crucial to avoid disruptions. Here are some key approaches:

- Incremental Updates: Instead of replacing the entire firmware, incremental updates only modify the changed portions. This reduces data transfer size, which is critical when updating multiple devices over a network. For example, if a security patch for a door lock controller is 50 KB, an incremental update ensures only that data is sent, rather than a full 2 MB firmware file.

- Scheduled Updates: Updates can be scheduled during low-traffic periods, such as late at night, to minimize impact on guests. This is especially important for systems controlling HVAC or lighting, where interruptions could be noticeable.

- Staged Rollouts: Deploy updates to a small group of devices first to test stability before rolling them out hotel-wide. This minimizes the risk of widespread issues if a bug is present in the update.

A well-planned firmware update strategy ensures that hotel operations run smoothly while maintaining the latest software capabilities on all PCBs.

2. Secure Bootloaders for Protection

A secure bootloader is the first line of defense in protecting hotel room control PCBs during OTA updates. It ensures that only verified and authentic firmware is loaded onto the device. Without a secure bootloader, malicious actors could exploit the update process to install harmful code, compromising systems like door locks or surveillance.

Here’s how secure bootloaders work:

- Digital Signatures: Firmware updates are signed with a cryptographic key. The bootloader checks this signature before installation. If the signature doesn’t match, the update is rejected.

- Encryption: Data transferred during OTA updates is encrypted to prevent interception. For instance, using AES-256 encryption ensures that even if data is intercepted, it remains unreadable without the key.

- Chain of Trust: The bootloader establishes a chain of trust by verifying each stage of the boot process, ensuring no unauthorized code runs on the PCB.

For hotel systems, where guest safety and privacy are paramount, integrating a secure bootloader into the PCB design is non-negotiable. It’s a small investment for massive peace of mind.

3. Remote Programming Capabilities

Remote programming is the backbone of OTA updates, allowing firmware to be updated without physical access to the PCB. For hotel room control systems, this means technicians don’t need to enter each room to perform maintenance, saving time and reducing labor costs.

To enable remote programming, PCBs must be equipped with:

- Network Connectivity: Devices need a way to connect to a central server, typically through Wi-Fi or a cellular module integrated into the PCB design. For example, a Wi-Fi module operating at 2.4 GHz can provide reliable connectivity with a range of up to 100 meters indoors.

- Update Client Software: A lightweight client on the PCB handles communication with the update server, downloading and installing new firmware. This client must be optimized to use minimal memory, often under 100 KB, to fit within the constraints of embedded systems.

- Power Management: Updates should not drain power or interrupt critical functions. Designers can implement low-power modes during update downloads, ensuring systems like door locks remain operational.

Remote programming transforms how hotel tech teams manage devices, making updates scalable and efficient across large properties.

4. Wireless Communication Protocols

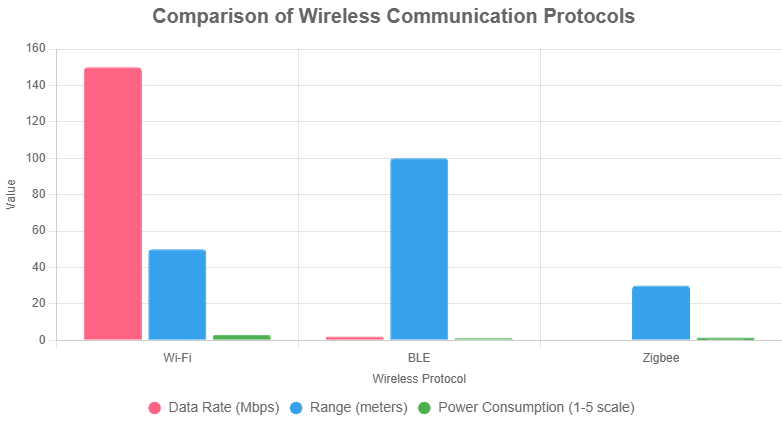

Wireless communication protocols determine how data is transmitted during OTA updates. Choosing the right protocol for hotel room control PCBs balances speed, range, and power consumption. Here are the most common options:

- Wi-Fi: Widely used due to its high speed and compatibility with existing hotel networks. Wi-Fi operates at speeds up to 150 Mbps on modern 2.4 GHz bands, making it ideal for large firmware files. However, it consumes more power than other options.

- Bluetooth Low Energy (BLE): Suitable for smaller updates or devices with limited power budgets. BLE offers speeds of about 1 Mbps and a range of 10-30 meters, perfect for localized updates in a single room.

- Zigbee: A low-power, mesh network protocol ideal for connecting multiple devices across a hotel. With a data rate of 250 Kbps and a range of 10-100 meters, Zigbee is energy-efficient for battery-powered systems like sensors.

The choice of protocol depends on the specific needs of the hotel system. For instance, Wi-Fi may be best for central control hubs, while Zigbee suits distributed sensors. PCB designers must integrate the appropriate wireless module to support the chosen protocol, ensuring reliable communication for OTA updates.

5. Update Rollback Mechanisms

No update process is foolproof. If a firmware update fails or introduces a bug, it could render hotel room systems unusable. Update rollback mechanisms provide a safety net by allowing the system to revert to the previous firmware version.

Here’s how rollback mechanisms work:

- Dual-Bank Memory: Many embedded systems use dual-bank flash memory, where one bank stores the current firmware and the other holds the new update. If the update fails, the system boots from the original bank. For example, a PCB with 512 KB of flash memory might allocate 256 KB per bank.

- Validation Checks: Before finalizing an update, the system runs validation tests to ensure the new firmware operates correctly. If it fails, the rollback process is triggered automatically.

- Backup Storage: A small portion of memory, often 10-20 KB, can store a minimal recovery image. This allows the device to boot into a safe mode and download a stable firmware version if all else fails.

For hotel room control PCBs, rollback mechanisms are critical to prevent costly downtime. Imagine a failed update locking guests out of their rooms—rollback capabilities can avert such disasters by restoring functionality in minutes.

Steps to Implement OTA Updates on Hotel Room Control PCBs

Now that we’ve covered the key components, let’s walk through the practical steps to implement OTA updates for hotel room control systems. This process ensures your PCBs are ready for remote updates while maintaining security and reliability.

- Design PCBs with OTA in Mind: Integrate wireless modules and sufficient flash memory (e.g., 512 KB or more) to support dual-bank storage for rollbacks. Ensure power management circuits can handle update processes without draining batteries.

- Develop Secure Bootloaders: Program bootloaders to verify digital signatures and encrypt data. Test the bootloader with sample firmware to confirm it rejects unsigned updates.

- Set Up a Central Update Server: Use a cloud-based or on-premises server to host firmware files. Configure the server to push updates to devices based on schedules or triggers, ensuring bandwidth usage stays below peak network capacity (e.g., under 50 Mbps during updates).

- Choose a Wireless Protocol: Select a protocol based on device needs. For central hubs, use Wi-Fi with a 2.4 GHz band for speed. For peripheral devices, consider Zigbee for low power consumption.

- Implement Rollback Mechanisms: Program dual-bank memory or backup storage to enable rollbacks. Test the system by intentionally deploying a faulty update to verify the rollback process works seamlessly.

- Test and Monitor: Conduct thorough testing in a controlled environment before full deployment. Monitor update success rates and device performance post-update to catch issues early.

Following these steps ensures that your hotel room control PCBs are equipped for OTA updates, minimizing risks and maximizing efficiency.

Challenges and Solutions in OTA Updates for Hotel Systems

While OTA updates offer immense benefits, they come with challenges. Here’s how to address common issues faced in hotel room control systems:

- Challenge: Network Congestion – With hundreds of devices updating simultaneously, network bandwidth can be strained.

Solution: Use staged rollouts and schedule updates during off-peak hours. Limit data transfer rates to 10-20% of total bandwidth capacity per device. - Challenge: Security Risks – OTA updates can be a target for hackers if not properly secured.

Solution: Implement end-to-end encryption and secure bootloaders. Regularly audit update servers for vulnerabilities. - Challenge: Update Failures – Power outages or connectivity issues can interrupt updates, leaving devices inoperable.

Solution: Design robust rollback mechanisms and ensure devices can resume interrupted downloads without data corruption.

By anticipating these challenges, hotel tech teams can ensure OTA updates enhance rather than hinder operations.

Benefits of OTA Updates for Hotel Room Control Systems

The advantages of implementing OTA updates on hotel room control PCBs are clear:

- Cost Savings: Eliminate the need for on-site technicians, reducing labor costs by up to 70% for large properties.

- Enhanced Security: Quickly deploy patches for vulnerabilities, protecting guest data and safety.

- Improved Guest Experience: Keep systems running smoothly with minimal downtime, ensuring guests enjoy uninterrupted services.

- Scalability: Easily manage updates for hundreds or thousands of devices from a single dashboard.

OTA updates are a game-changer for the hospitality industry, offering a modern solution to age-old maintenance challenges.

Conclusion

Implementing Over-The-Air (OTA) updates on hotel room control PCBs is a vital step toward modernizing hotel operations. By focusing on firmware update strategies, secure bootloaders, remote programming, wireless communication protocols, and update rollback mechanisms, tech teams can ensure systems remain secure, efficient, and reliable. Whether you’re a PCB designer or a hotel tech manager, adopting OTA updates saves time, reduces costs, and enhances guest satisfaction. With careful planning and the right tools, your hotel can stay ahead in the smart technology race, delivering seamless experiences to every guest.

At ALLPCB, we’re committed to supporting your journey with high-quality PCB manufacturing and assembly services tailored for smart systems. Let’s build the future of hospitality technology together.

ALLPCB

ALLPCB