If you're wondering whether to handle PCB cleaning yourself or hire professional services, the decision often comes down to cost, time, equipment, and the complexity of your project. DIY PCB cleaning can save money for small-scale or hobbyist projects, but professional PCB cleaning services are often worth the investment for larger batches, intricate designs, or when reliability is critical. In this comprehensive guide, we'll explore the pros and cons of both approaches, dive into the cost of professional PCB cleaning, discuss the equipment used, and help you determine when to outsource PCB cleaning for optimal results.

Why PCB Cleaning Matters

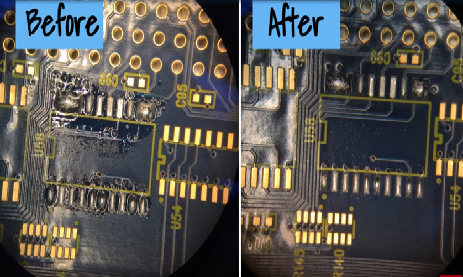

Printed Circuit Boards (PCBs) are the backbone of electronic devices, and keeping them clean is essential for performance and longevity. During manufacturing, assembly, or repair, contaminants like flux residues, dust, grease, and solder particles can accumulate on the board. These contaminants can cause short circuits, corrosion, or signal interference, leading to device failure. Whether you're a hobbyist working on a single board or a manufacturer producing thousands, proper cleaning ensures reliability and functionality.

DIY PCB Cleaning: Pros, Cons, and Methods

For hobbyists or small-scale projects, DIY PCB cleaning can be a cost-effective solution. It allows you to maintain control over the process and avoid outsourcing costs. However, it comes with limitations in terms of equipment, expertise, and scalability. Let's break down the key aspects of DIY PCB cleaning.

Advantages of DIY PCB Cleaning

- Cost Savings: Cleaning your own PCBs eliminates the need to pay for professional services. Basic cleaning supplies like isopropyl alcohol (IPA) and brushes can cost as little as $10–$20.

- Control: You have full oversight of the cleaning process, ensuring that delicate components are handled with care.

- Learning Opportunity: DIY cleaning helps you understand your boards better, which can be valuable for troubleshooting or future projects.

Disadvantages of DIY PCB Cleaning

- Time-Consuming: Cleaning even a single board manually can take 30 minutes to an hour, especially for intricate designs with many components.

- Limited Equipment: Most hobbyists lack access to advanced tools like ultrasonic cleaners or specialized solvents, which can result in incomplete cleaning.

- Risk of Damage: Without proper knowledge, you might damage sensitive components or leave harmful residues behind.

Common DIY PCB Cleaning Methods

Here are some widely used techniques for DIY PCB cleaning that target the long tail keyword "DIY PCB cleaning":

- Isopropyl Alcohol and Brush: Use 90% or higher IPA with a soft-bristled brush to scrub away flux residues. This method works well for light contamination and costs less than $15 for supplies.

- Compressed Air: Blow away dust and debris using canned air. This is a quick, non-contact method but won't remove sticky residues like flux.

- Ultrasonic Cleaning (Advanced DIY): For those with access to an ultrasonic cleaner (costing around $50–$150 for basic models), you can submerge the PCB in a cleaning solution to remove contaminants. Be cautious with components that aren't rated for immersion.

Professional PCB Cleaning Services: Pros, Cons, and Costs

When dealing with high-volume production, complex assemblies, or mission-critical applications, professional PCB cleaning services become a more viable option. These services use specialized equipment and expertise to ensure thorough cleaning without risking damage. Let's explore the details, including the cost of professional PCB cleaning.

Advantages of Professional PCB Cleaning Services

- High-Quality Results: Professionals use advanced equipment like automated ultrasonic cleaners and vapor degreasers to remove even the toughest contaminants.

- Time Efficiency: Cleaning hundreds or thousands of boards manually is impractical. Professional services can handle large batches quickly.

- Reduced Risk: Trained technicians know how to handle delicate components and avoid damaging boards, ensuring reliability for sensitive applications.

Disadvantages of Professional PCB Cleaning Services

- Higher Costs: The cost of professional PCB cleaning can range from $5 to $50 per board, depending on the complexity, size, and volume. Additional fees may apply for rush orders or specialized cleaning requirements.

- Less Control: Outsourcing means trusting a third party with your boards, which can be a concern if intellectual property or design confidentiality is an issue.

- Turnaround Time: Depending on the service provider, you may face delays, especially during peak demand periods.

Cost of Professional PCB Cleaning

The cost of professional PCB cleaning varies widely based on several factors:

- Board Size and Complexity: Larger boards or those with dense component layouts cost more to clean due to the time and resources required.

- Volume: Bulk orders often come with discounts. For example, cleaning 100 boards might cost $10 per board, while a single board could cost $30.

- Type of Contaminants: Heavy flux residues or conformal coating removal can increase costs due to the need for specialized solvents or processes.

- Turnaround Time: Expedited services can add 20–50% to the total cost.

On average, expect to pay between $500 and $5,000 for cleaning a batch of 100–1,000 boards, though quotes can vary based on your specific needs and location.

Equipment for Professional PCB Cleaning

Professional services rely on specialized tools to achieve consistent, high-quality results. Understanding the equipment for professional PCB cleaning can help you appreciate why outsourcing might be necessary for certain projects.

- Ultrasonic Cleaners: These machines use high-frequency sound waves to agitate a cleaning solution, removing contaminants from hard-to-reach areas. Industrial-grade ultrasonic cleaners can cost between $1,000 and $10,000.

- Vapor Degreasers: These systems use solvent vapors to dissolve and remove residues. They are ideal for heavy contamination but can cost upwards of $20,000 for professional setups.

- Aqueous Cleaning Systems: These use water-based solutions and are often paired with spray or immersion techniques. Equipment costs range from $5,000 to $50,000 depending on capacity.

- Inspection Tools: Professionals use magnifying tools or automated optical inspection (AOI) systems to ensure no residues remain. AOI systems can cost $10,000 or more.

For small businesses or hobbyists, investing in such equipment is often impractical due to the high upfront costs and maintenance requirements. This is a key reason many choose to outsource cleaning instead of building an in-house capability.

When to Outsource PCB Cleaning

Deciding when to outsource PCB cleaning depends on your project needs, budget, and resources. Here are some scenarios where outsourcing makes the most sense, along with situations where DIY might suffice.

Outsource PCB Cleaning When:

- High Volume: If you're dealing with batches of 50 or more boards, professional services save time and ensure consistency.

- Complex Designs: Boards with fine-pitch components, high-density layouts, or sensitive materials (e.g., RF circuits with impedance values around 50 ohms) require expert handling to avoid damage.

- Critical Applications: For industries like aerospace, medical, or automotive, where failure is not an option, professional cleaning ensures reliability and compliance with standards like IPC-6012.

- Lack of Equipment: If you don't have access to advanced cleaning tools or the budget to purchase them, outsourcing is a practical choice.

Stick to DIY PCB Cleaning When:

- Small Projects: For one-off prototypes or small batches (under 10 boards), DIY cleaning is often sufficient and cost-effective.

- Budget Constraints: If outsourcing costs exceed your project budget, DIY methods can get the job done with minimal investment.

- Learning or Experimentation: Hobbyists or students working on non-critical projects can benefit from the hands-on experience of cleaning their own boards.

Key Decision Factors

To make an informed choice, consider the following:

- Time vs. Cost: Calculate how much time DIY cleaning will take compared to the cost of professional services. If your hourly rate is $50 and cleaning 10 boards takes 5 hours, that's $250 in time—potentially more than outsourcing.

- Risk Assessment: Evaluate the potential cost of failure. A damaged board in a critical application could lead to losses far exceeding the cost of professional cleaning.

- Scalability: If your production volume is likely to increase, building a relationship with a professional service provider can streamline future projects.

Tips for Choosing a Professional PCB Cleaning Service

If you decide to outsource, selecting the right service provider is crucial. Here are some practical tips to ensure you get the best value and quality:

- Check Experience: Look for providers with a proven track record in cleaning PCBs for your specific industry or application.

- Request Quotes: Compare pricing from multiple providers, keeping in mind that the cheapest option isn't always the best in terms of quality.

- Verify Equipment: Ensure the provider uses modern, well-maintained equipment suited to your board's requirements.

- Confirm Turnaround Time: Make sure their processing times align with your project deadlines.

- Review Standards: Choose a provider that adheres to industry standards like IPC or ISO for cleaning and quality assurance.

Conclusion: Making the Right Choice for Your PCB Cleaning Needs

Deciding between DIY PCB cleaning and professional PCB cleaning services depends on your project's scale, budget, and criticality. DIY methods are ideal for small, non-critical projects where cost savings and hands-on control are priorities. However, when dealing with high volumes, complex designs, or applications where reliability is paramount, outsourcing to professional services offers superior results, despite the higher cost of professional PCB cleaning.

By understanding the equipment for professional PCB cleaning and evaluating when to outsource PCB cleaning, you can make an informed decision that balances cost, time, and quality. Whether you choose to clean your boards yourself or partner with a trusted service provider, the goal remains the same: ensuring your PCBs perform reliably in their intended applications.

For all your PCB needs, from design to manufacturing and beyond, trust a reliable partner to support your journey. We're here to help you achieve success with every project.

ALLPCB

ALLPCB