If you're exploring the role of Direct Bonded Copper (DBC) PCBs in electric vehicles (EVs), particularly in power inverters, you've come to the right place. DBC technology is a game-changer in automotive PCB design, offering high reliability and excellent thermal management for demanding applications like EV power inverters. In this blog, we'll take a deep dive into how DBC PCBs work, their advantages in automotive systems, and why they are critical for thermal cycling and performance in electric vehicles. Let's explore this innovative solution and its impact on the future of EV design.

What Are Direct Bonded Copper PCBs and Why Do They Matter in EVs?

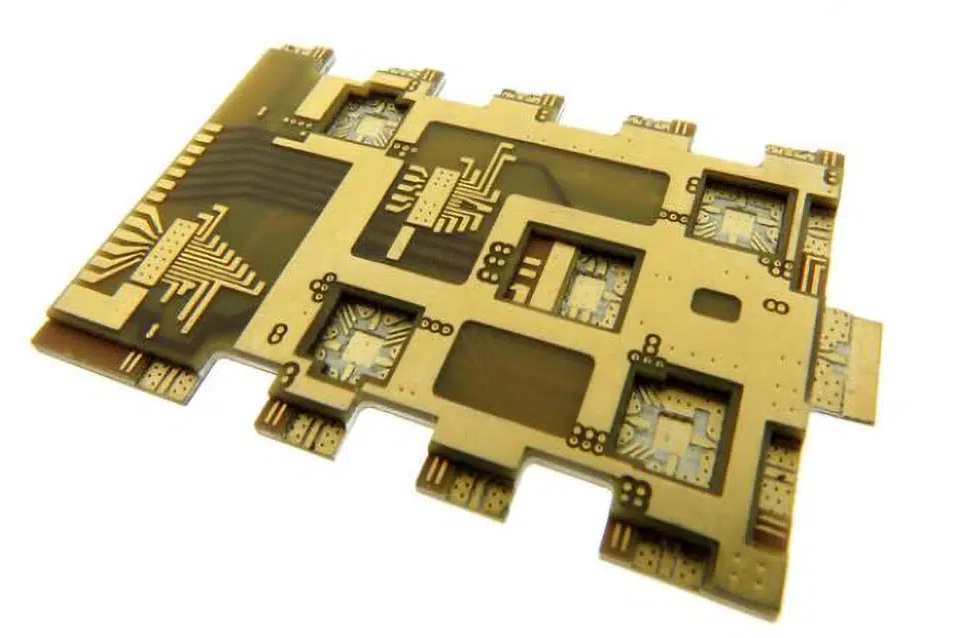

Direct Bonded Copper (DBC) PCBs are a specialized type of substrate used in high-power electronics. Unlike traditional PCBs, DBC substrates feature a ceramic base, often made of materials like aluminum oxide (Al2O3) or aluminum nitride (AlN), with copper layers directly bonded to both sides. This structure provides superior thermal conductivity and electrical insulation, making DBC ideal for applications where heat dissipation and reliability are critical.

In electric vehicles, power inverters play a vital role by converting direct current (DC) from the battery into alternating current (AC) to drive the electric motor. These inverters handle high currents and voltages, often exceeding 400V and 100A, generating significant heat in the process. DBC PCBs are uniquely suited for this environment due to their ability to manage thermal stress and ensure consistent performance under extreme conditions.

The Role of Power Inverters in Electric Vehicles

Before diving deeper into DBC technology, it's important to understand the function of power inverters in EVs. The inverter is the heart of an electric vehicle's drivetrain, responsible for controlling the motor's speed and torque. It operates by switching high currents at rapid frequencies, often in the range of 10-20 kHz, to create the AC waveform needed for the motor.

This high-frequency switching generates substantial heat due to power losses in the semiconductor components, such as insulated-gate bipolar transistors (IGBTs) or silicon carbide (SiC) MOSFETs. If this heat isn't managed effectively, it can lead to component failure, reduced efficiency, and shorter lifespan of the inverter system. This is where DBC PCBs come in, providing a robust solution for thermal management and high-reliability performance in automotive designs.

Key Advantages of DBC in EV Power Inverters

Using DBC technology in EV power inverters offers several benefits that make it a preferred choice for automotive PCB design. Let's break down these advantages to see why DBC stands out in high-power applications.

1. Superior Thermal Conductivity for Heat Dissipation

One of the standout features of DBC PCBs is their exceptional thermal conductivity. The ceramic layer in DBC substrates, especially when using aluminum nitride, can achieve thermal conductivity values of up to 170-180 W/m·K, far surpassing traditional FR4 materials (around 0.3 W/m·K). This allows DBC to efficiently transfer heat away from power components in the inverter, preventing overheating and maintaining optimal operating temperatures.

In an EV power inverter, where components can reach temperatures above 150°C during operation, effective heat dissipation is non-negotiable. DBC ensures that thermal energy is quickly moved to heat sinks or cooling systems, reducing the risk of thermal runaway and extending the lifespan of the inverter.

2. High-Reliability Under Thermal Cycling

Thermal cycling, the repeated heating and cooling of components, is a major challenge in EV systems. As vehicles start, stop, and operate under varying loads, the power inverter experiences significant temperature fluctuations. These cycles can cause mechanical stress due to differences in thermal expansion between materials, leading to cracks or delamination in traditional PCBs.

DBC substrates are designed to withstand thermal cycling stress. The direct bonding of copper to ceramic creates a strong, durable interface that resists cracking even after thousands of cycles. Studies have shown that DBC can endure over 10,000 thermal cycles between -40°C and 150°C without significant degradation, making it a high-reliability PCB solution for automotive environments.

3. Excellent Electrical Insulation for Safety

In high-voltage EV systems, electrical insulation is critical to prevent short circuits and ensure safety. The ceramic layer in DBC PCBs provides high dielectric strength, often exceeding 20 kV/mm, which ensures reliable insulation between the copper layers and other conductive parts. This is particularly important in power inverters, where voltages can spike during switching operations.

By combining strong insulation with high thermal performance, DBC PCBs help maintain the integrity of the inverter system, protecting both the vehicle and its passengers from electrical hazards.

4. Compact Design for Space Efficiency

Space is at a premium in electric vehicle design, where engineers aim to maximize battery capacity and performance within a limited footprint. DBC PCBs support compact designs by allowing higher power densities. Their ability to handle high currents—often up to 200A or more per module—means fewer components are needed to achieve the same output, reducing the overall size of the inverter.

This compactness also translates to lighter weight, which is crucial for improving an EV's range and efficiency. With DBC, manufacturers can build smaller, more efficient power inverters without sacrificing reliability or performance.

DBC in Automotive PCB Design: Challenges and Solutions

While DBC offers significant advantages, it's not without its challenges in automotive PCB design. Understanding these hurdles and how they can be addressed is key to leveraging DBC technology effectively in EV power inverters.

Challenge 1: Higher Manufacturing Costs

DBC substrates are more expensive to produce compared to standard FR4 or even metal core PCBs. The process of bonding copper to ceramic requires precise control of temperature and pressure, often at levels above 1000°C, which adds to the cost. For EV manufacturers, this can be a barrier, especially in cost-sensitive markets.

Solution: The long-term benefits of DBC, such as improved reliability and reduced maintenance, often outweigh the initial costs. Additionally, as production scales up and manufacturing techniques improve, the cost of DBC substrates is expected to decrease, making them more accessible for widespread use in automotive applications.

Challenge 2: Limited Design Flexibility

Unlike multilayer PCBs, DBC substrates typically have fewer layers, which can limit design flexibility for complex circuits. This is a concern in power inverters that may require intricate routing for control signals alongside high-power paths.

Solution: Hybrid designs that combine DBC for high-power sections with traditional PCBs for control circuitry can address this issue. This approach ensures that the inverter benefits from DBC's thermal and power-handling capabilities while maintaining flexibility for signal processing.

Applications of DBC Beyond Power Inverters in EVs

While this blog focuses on DBC in EV power inverters, it's worth noting that this technology has broader applications in electric vehicles and beyond. For instance, DBC is widely used in battery management systems (BMS) to handle high currents during charging and discharging. It's also found in DC-DC converters, onboard chargers, and even renewable energy systems like solar inverters, where thermal management and reliability are equally important.

In each of these applications, the core advantages of DBC—high thermal conductivity, durability under thermal cycling, and reliable electrical insulation—make it a versatile choice for high-power electronics.

How DBC Contributes to the Future of Electric Vehicles

As the electric vehicle industry continues to grow, the demand for efficient, reliable, and compact power electronics will only increase. DBC PCBs are poised to play a central role in this evolution, enabling inverters and other components to handle higher power levels and operate under harsher conditions without failure.

For instance, the shift toward silicon carbide (SiC) semiconductors in EV inverters, which operate at higher switching frequencies (up to 50 kHz) and temperatures (above 200°C), will require substrates like DBC that can keep up with these demands. By supporting faster, more efficient power conversion, DBC helps improve the overall range and performance of electric vehicles, bringing us closer to a sustainable transportation future.

Why Choose DBC for High-Reliability PCB Needs in Automotive Design?

In summary, Direct Bonded Copper PCBs offer a powerful solution for the unique challenges of EV power inverters and automotive PCB design. Their ability to manage heat, endure thermal cycling, and provide strong electrical insulation makes them an ideal choice for high-reliability applications. While there are challenges like cost and design limitations, the benefits of DBC far outweigh these drawbacks, especially as manufacturing processes continue to advance.

At ALLPCB, we understand the importance of cutting-edge materials and designs in pushing the boundaries of electric vehicle technology. Whether you're designing power inverters or other critical components, DBC substrates can provide the performance and durability needed to succeed in the fast-evolving automotive industry.

Conclusion: The Power of DBC in EV Innovation

Direct Bonded Copper PCBs are more than just a component; they are a cornerstone of modern EV design, particularly in power inverters. By addressing the critical needs of thermal management, reliability under thermal cycling, and high-power handling, DBC technology ensures that electric vehicles can perform at their best, even under the most demanding conditions. As the automotive industry moves toward greater electrification, DBC will continue to be a key enabler of innovation, helping manufacturers build safer, more efficient, and longer-lasting vehicles.

With a deep understanding of DBC advantages in automotive applications, engineers and designers can make informed decisions to optimize their systems. The future of electric vehicles is bright, and DBC PCBs are helping to light the way.

ALLPCB

ALLPCB