Designing printed circuit boards (PCBs) for infotainment systems in vehicles requires balancing performance, reliability, and cost. If you're searching for ways to reduce expenses without sacrificing quality, you're in the right place. This blog dives into actionable PCB cost reduction strategies, tips for component sourcing cheap PCB options, and techniques for PCB manufacturing cost optimization and layer count optimization PCB. We'll guide you through practical steps to create efficient designs tailored for infotainment systems, helping you save money while maintaining high standards.

Infotainment systems are the heart of modern automotive experiences, combining navigation, entertainment, and connectivity. However, the PCBs powering these systems can become expensive due to complex designs and high component costs. By applying the strategies below, you can streamline your design process and cut expenses significantly. Let’s explore how to achieve this with detailed tips and insights.

Why Cost-Effective PCB Design Matters for Infotainment Systems

Infotainment systems are packed with features like touchscreens, audio processing, Bluetooth connectivity, and GPS. Each feature adds layers of complexity to the PCB, driving up costs in design, components, and manufacturing. A poorly optimized PCB can lead to higher production expenses, longer assembly times, and even reliability issues down the line. Focusing on cost-effective design from the start ensures that your infotainment system remains competitive in price while delivering top-notch performance.

Optimizing costs doesn't mean cutting corners. It’s about making smart choices in layout, materials, and sourcing to achieve savings. For instance, reducing the number of layers in a PCB or selecting widely available components can lower expenses without impacting functionality. Let’s break down the key strategies to make this happen.

Key PCB Cost Reduction Strategies for Infotainment Systems

Reducing costs starts with a focus on design efficiency and strategic planning. Here are some proven PCB cost reduction strategies tailored for infotainment system designs.

1. Simplify the PCB Layout

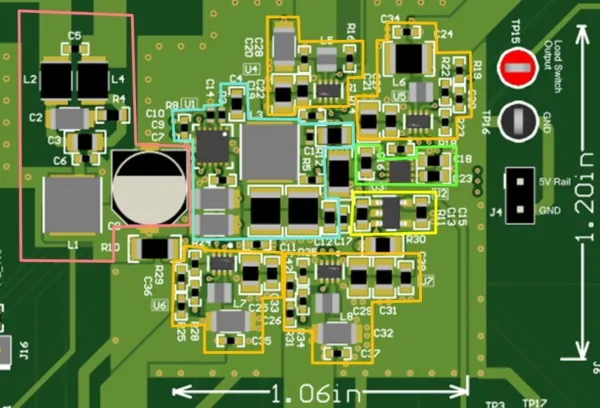

A complex PCB layout with unnecessary traces or overcrowded components can increase manufacturing costs. Simplifying the layout reduces material usage and shortens production time. Focus on placing components logically to minimize trace lengths, which also improves signal integrity—a critical factor for infotainment systems handling high-speed data for video and audio.

For example, group related components, such as audio amplifiers and connectors, close together to avoid long traces that could introduce noise. Use design software to simulate signal paths and ensure impedance matching, targeting values like 50 ohms for high-frequency signals. This approach not only cuts costs but also boosts performance.

2. Optimize Layer Count for Cost Savings

One of the most impactful areas for layer count optimization PCB is reducing the number of layers in your design. Each additional layer increases manufacturing costs due to extra materials and processing steps. For infotainment systems, aim for a balance between functionality and layer count. Many designs can function effectively with 4 to 6 layers instead of 8 or more.

Evaluate whether all signals require separate layers. For instance, power and ground planes can often be combined on a single layer with proper isolation. This reduces costs by up to 20% in some cases, depending on the complexity of the board. Always test the design for thermal and electrical performance to ensure that reducing layers doesn’t compromise reliability.

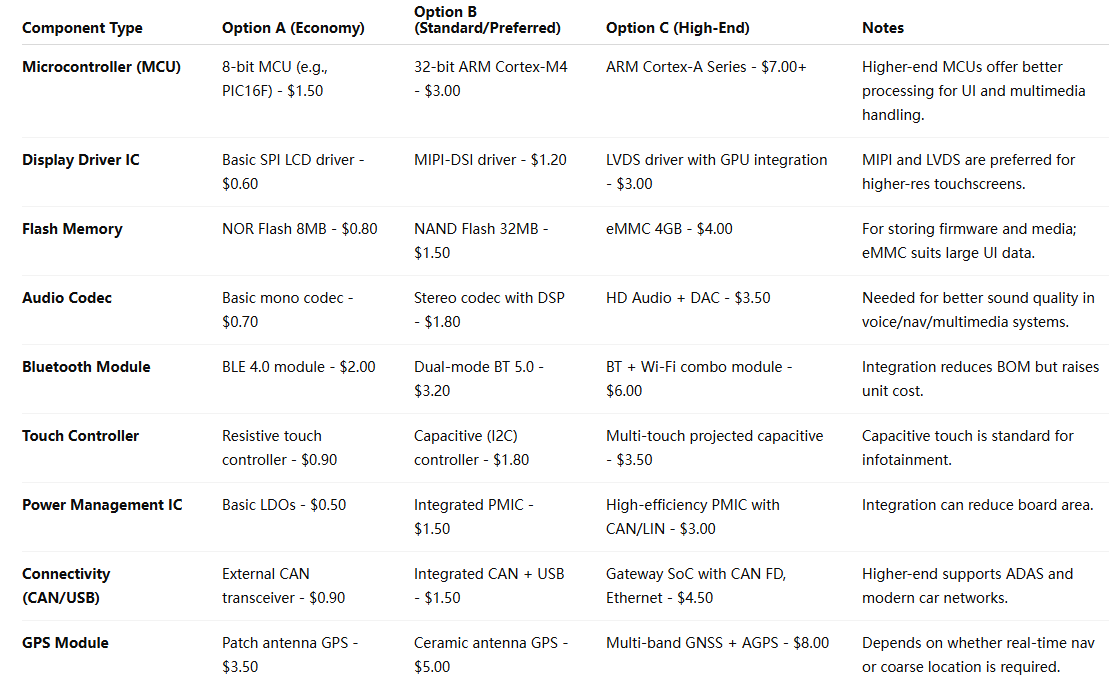

3. Standardize Component Sizes and Types

Using non-standard or custom components can drive up costs due to limited availability and higher pricing. Stick to standard component sizes, such as 0402 or 0603 for resistors and capacitors, which are widely available and cheaper to source. This also simplifies assembly, as manufacturers are equipped to handle standard sizes efficiently.

For infotainment systems, prioritize components that meet automotive-grade standards (like AEC-Q100) while keeping costs low. Avoid over-specifying components—don’t use a high-end processor if a mid-range one meets your performance needs. This strategy aligns with effective component sourcing cheap PCB practices.

Component Sourcing: Finding Affordable and Reliable Options

Sourcing components wisely is a cornerstone of component sourcing cheap PCB strategies. Infotainment systems often require a mix of microcontrollers, RF modules, and display drivers, which can be expensive if not sourced strategically. Here’s how to keep costs down.

1. Buy in Bulk for Volume Discounts

Purchasing components in bulk can lead to significant savings, especially for high-volume production runs. Work with suppliers to negotiate discounts for large orders of capacitors, resistors, and ICs. For instance, buying 10,000 units of a standard capacitor might reduce the per-unit cost by 30% compared to buying 1,000 units.

Plan your inventory needs ahead of time to take advantage of these discounts. This approach is especially useful for infotainment system PCBs, where certain components like connectors are used repeatedly across designs.

2. Use Alternative Components with Similar Specs

If a specific component is too expensive or hard to source, look for alternatives with similar specifications. For example, if a particular Bluetooth module costs $5 per unit, search for a compatible module with the same frequency range (2.4 GHz) and data rate (up to 3 Mbps) at a lower price point. Always verify compatibility through testing to avoid performance issues.

Maintain a database of approved alternatives for key components to streamline future sourcing. This reduces dependency on single suppliers and keeps costs under control.

PCB Manufacturing Cost Optimization Techniques

Manufacturing is where many hidden costs can emerge if not managed properly. Implementing PCB manufacturing cost optimization strategies ensures that your infotainment system PCBs are produced efficiently and affordably.

1. Choose Cost-Effective Materials

The choice of PCB material impacts both cost and performance. For infotainment systems, FR-4 is often a cost-effective and reliable choice for most designs. It’s widely available and suitable for operating temperatures up to 130°C, which meets automotive requirements. Avoid exotic materials like high-frequency laminates unless your design specifically demands them for RF performance.

Additionally, opt for standard board thicknesses (like 1.6 mm) to avoid custom fabrication fees. These small decisions can reduce material costs by 10-15% per board in large production runs.

2. Design for Manufacturability (DFM)

Designing with manufacturing in mind can prevent costly revisions and delays. Follow DFM guidelines, such as maintaining minimum trace widths (e.g., 6 mils for standard processes) and spacing to avoid fabrication errors. Place vias strategically to minimize drilling costs, as excessive or poorly placed vias can increase production time.

For infotainment PCBs, ensure that high-power components like voltage regulators have adequate heat dissipation through proper pad sizing. Neglecting DFM can lead to rework costs, which might add 5-10% to the overall budget for complex designs.

3. Panelization for Efficient Production

Panelization involves arranging multiple PCBs on a single panel during manufacturing to maximize material usage. For infotainment system PCBs, which are often small to medium in size, panelization can reduce waste and lower costs per unit. Work with your manufacturer to determine the optimal panel size, ensuring that breakaway tabs or scoring lines are easy to process.

This technique can cut manufacturing costs by up to 20% for high-volume orders, making it a powerful tool for cost optimization.

Balancing Cost and Performance in Infotainment PCBs

While cost reduction is essential, infotainment systems must meet strict performance and reliability standards. High-speed data transmission for streaming or navigation requires careful attention to signal integrity. Ensure that cost-cutting measures don’t interfere with critical aspects like impedance control (targeting 50-75 ohms for differential pairs) or noise reduction.

Thermal management is another concern, as components like processors can generate significant heat in confined automotive environments. Use copper pours for heat dissipation and avoid reducing layer count if it compromises power distribution. Test prototypes under real-world conditions to validate performance before scaling up production.

Additional Tips for Long-Term Cost Savings

Beyond immediate design and manufacturing choices, consider these long-term strategies for sustained savings.

- Leverage Simulation Tools: Use software to simulate electrical and thermal performance before prototyping. Identifying issues early can save thousands in redesign costs.

- Partner with Reliable Suppliers: Build relationships with trusted component and manufacturing partners to ensure consistent quality and pricing.

- Plan for Scalability: Design PCBs with future upgrades in mind, avoiding the need for complete redesigns as infotainment features evolve.

Conclusion: Building Cost-Effective Infotainment System PCBs

Creating cost-effective PCBs for infotainment systems is achievable with the right approach. By focusing on PCB cost reduction strategies, smart component sourcing cheap PCB options, PCB manufacturing cost optimization, and layer count optimization PCB, you can significantly lower expenses while maintaining quality. Simplifying layouts, standardizing components, and designing for manufacturability are just a few ways to make a big impact.

At ALLPCB, we’re committed to helping you achieve efficient and affordable PCB designs for automotive applications. Whether you’re working on a small batch or a high-volume run, these tips can guide you toward smarter, more economical solutions. Start implementing these strategies in your next project to see the savings add up without compromising on the performance your infotainment system needs.

ALLPCB

ALLPCB