In the fast-paced world of gaming consoles, performance is everything. As gamers demand faster processing, higher graphics fidelity, and seamless connectivity, the materials used in printed circuit boards (PCBs) play a critical role in meeting these expectations. While FR-4 has long been the standard for PCB manufacturing due to its affordability and versatility, cutting-edge gaming consoles are pushing the limits of what this traditional material can achieve. So, what are the advanced PCB materials that can take gaming hardware to the next level? In this blog, we’ll explore high-performance options beyond FR-4, focusing on gaming console PCB material selection and the benefits of advanced laminates for superior performance.

Whether you're an engineer designing the next big console or a tech enthusiast curious about the hardware behind your favorite games, this guide will dive deep into high-performance PCB materials, including Rogers PCB for gaming consoles, ceramic PCB options, and other advanced laminates. Let’s uncover how these materials can enhance speed, thermal management, and signal integrity for the ultimate gaming experience.

Why PCB Material Selection Matters for Gaming Consoles

Gaming consoles are complex systems that require high-speed data transfer, minimal signal loss, and efficient heat dissipation to handle intense workloads. The PCB, as the backbone of the console’s electronics, must support powerful processors, high-bandwidth memory, and advanced graphics cards. Traditional FR-4, a fiberglass-epoxy laminate, works well for basic applications but often falls short in high-frequency and high-power scenarios common in modern gaming hardware.

For instance, FR-4 typically has a dielectric constant (Dk) of around 4.5, which can lead to signal delays and losses at frequencies above 1 GHz. In contrast, gaming consoles operating with high-speed signals—sometimes exceeding 10 GHz for data transfer between components—need materials with lower Dk values and better signal integrity. This is where advanced PCB materials come into play, offering tailored properties for gaming console PCB material selection.

The Limitations of FR-4 in Cutting-Edge Gaming Consoles

FR-4 has been the go-to material for PCBs for decades due to its cost-effectiveness and mechanical strength. However, as gaming consoles evolve with faster processors and 5G connectivity, FR-4 struggles to keep up. Here are some key limitations:

- Signal Loss at High Frequencies: FR-4’s higher dielectric constant and loss tangent (typically 0.02) cause significant signal attenuation at frequencies above 1-2 GHz, which can impact data transfer rates in modern consoles.

- Thermal Management Issues: Gaming consoles generate substantial heat during prolonged use. FR-4’s thermal conductivity is relatively low (around 0.3 W/mK), making it less effective at dissipating heat from high-power components.

- Impedance Control: Maintaining consistent impedance is crucial for high-speed signals. FR-4’s variability in dielectric properties can lead to impedance mismatches, affecting performance.

These challenges highlight the need for high-performance PCB materials that can address the unique demands of gaming hardware. Let’s explore some of the advanced options that are shaping the future of console design.

High-Performance PCB Materials for Gaming Consoles

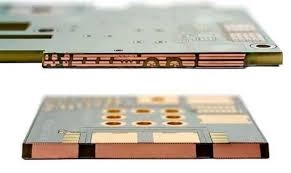

Advanced PCB materials are engineered to overcome the shortcomings of FR-4, providing better electrical performance, thermal stability, and reliability. Below, we’ll discuss some of the top choices for gaming console PCB material selection, including Rogers PCB for gaming consoles and ceramic PCB options.

1. Rogers PCB Materials: Precision for High-Frequency Signals

Rogers PCB materials are a popular choice for applications requiring excellent high-frequency performance. Unlike FR-4, Rogers laminates are designed with low dielectric constants (Dk as low as 2.2) and extremely low loss tangents (as low as 0.0009). This makes them ideal for gaming consoles where high-speed data transfer and minimal signal loss are essential.

For example, in a gaming console transmitting data at 10 GHz or higher between the CPU and GPU, a Rogers PCB can maintain signal integrity with minimal attenuation. These materials also offer tighter control over impedance, ensuring consistent performance across the board. Additionally, Rogers laminates have better thermal stability, with some variants supporting temperatures up to 280°C, compared to FR-4’s typical limit of around 130°C.

While Rogers PCB for gaming consoles comes at a higher cost, the performance benefits make it a worthwhile investment for cutting-edge hardware where every millisecond counts.

2. Ceramic PCB Options: Superior Thermal Management

Ceramic PCB materials are another advanced option gaining traction in gaming console design. Made from materials like alumina (Al2O3) or aluminum nitride (AlN), ceramic PCBs excel in thermal conductivity, with values ranging from 20 W/mK to 170 W/mK. This is a massive improvement over FR-4’s 0.3 W/mK, making ceramic PCB for gaming consoles an excellent choice for managing heat in high-power systems.

Modern consoles often run at high power levels, with components like GPUs generating significant heat during 4K rendering or extended gameplay. A ceramic PCB can efficiently dissipate this heat, preventing thermal throttling and extending the lifespan of the hardware. Additionally, ceramic materials offer excellent electrical insulation and stability, reducing the risk of short circuits under high voltage.

However, ceramic PCBs are more expensive and brittle compared to other materials, which can pose challenges during manufacturing and assembly. Despite these drawbacks, their thermal performance makes them a strong candidate for premium gaming hardware.

3. Advanced PCB Laminates: Tailored Solutions for Gaming Hardware

Beyond Rogers and ceramic options, advanced PCB laminates for gaming consoles include a variety of specialized materials designed for specific performance needs. These laminates often combine low-loss properties with enhanced thermal and mechanical stability. Some notable examples include:

- PTFE-Based Laminates: Polytetrafluoroethylene (PTFE) materials offer a low dielectric constant (around 2.1) and minimal signal loss, similar to Rogers materials. They are ideal for high-frequency applications in gaming consoles, such as wireless connectivity modules supporting Wi-Fi 6 or 5G.

- High-Tg Epoxy Laminates: These laminates improve on traditional FR-4 by offering a higher glass transition temperature (Tg) of up to 180°C. They provide better thermal resistance for consoles running at high temperatures over long periods.

- Polyimide Laminates: Known for their flexibility and high thermal stability (up to 260°C), polyimide materials are often used in compact gaming devices or flexible PCB designs within controllers.

Advanced PCB laminates for gaming consoles allow designers to customize boards based on specific requirements, balancing cost, performance, and durability.

Key Factors in Gaming Console PCB Material Selection

Choosing the right PCB material for a gaming console involves balancing several factors. Here are the key considerations to keep in mind during gaming console PCB material selection:

- Frequency and Signal Speed: For consoles with high-speed data transfer, materials with low dielectric constants and loss tangents (like Rogers PCB) are critical to minimize signal delays and losses.

- Thermal Performance: High-power components require materials with excellent thermal conductivity (like ceramic PCB) to prevent overheating and maintain performance during intense gaming sessions.

- Cost vs. Performance: While advanced materials offer superior properties, they come at a higher cost. Designers must weigh the benefits against budget constraints, especially for mass-produced consoles.

- Manufacturing Compatibility: Some materials, like ceramics, are more challenging to process and assemble. Compatibility with existing manufacturing techniques is essential to avoid production delays.

- Durability and Reliability: Gaming consoles are often subjected to long hours of use. Materials must withstand thermal cycling, mechanical stress, and environmental factors over time.

By carefully evaluating these factors, engineers can select high-performance PCB materials that optimize both functionality and cost for cutting-edge gaming hardware.

Benefits of Using Advanced PCB Materials in Gaming Consoles

Switching to advanced PCB materials offers several advantages for gaming console performance and longevity. Here’s how these materials make a difference:

- Faster Processing and Data Transfer: Low-loss materials enable higher signal speeds, reducing latency and improving gameplay responsiveness. For example, a Rogers PCB can support data rates of 25 Gbps or more, crucial for next-gen consoles.

- Better Heat Management: Materials like ceramic PCBs dissipate heat efficiently, preventing performance drops due to thermal throttling and extending component life.

- Enhanced Graphics and Connectivity: High-frequency materials support advanced graphics rendering and faster wireless connections, ensuring smooth 4K streaming and low-latency online gaming.

- Compact and Lightweight Designs: Advanced laminates often allow for thinner boards and smaller footprints, enabling sleeker console designs without sacrificing performance.

These benefits translate directly into a better user experience, making advanced PCB materials a game-changer for the industry.

Future Trends in PCB Materials for Gaming Consoles

As gaming technology continues to evolve, so do the materials used in PCB design. Here are some emerging trends in high-performance PCB materials for gaming consoles:

- Hybrid Material Stacks: Combining different materials (e.g., FR-4 with Rogers layers) in a single PCB to balance cost and performance for specific circuit areas.

- Nano-Engineered Laminates: New materials with nano-fillers are being developed to further reduce dielectric loss and improve thermal conductivity at a lower cost.

- Sustainable Materials: With growing environmental concerns, manufacturers are exploring eco-friendly PCB materials that maintain high performance while reducing ecological impact.

These innovations promise to push the boundaries of gaming hardware, delivering even faster, more efficient, and sustainable consoles in the years ahead.

Conclusion: Elevating Gaming with Advanced PCB Materials

The world of gaming consoles is evolving at a breakneck pace, and traditional FR-4 materials are no longer enough to meet the demands of modern hardware. By exploring high-performance PCB materials like Rogers PCB for gaming consoles, ceramic PCB options, and advanced PCB laminates, designers can create systems that deliver unparalleled speed, thermal efficiency, and reliability. Gaming console PCB material selection is a critical step in building hardware that keeps up with the latest trends in graphics, connectivity, and processing power.

At ALLPCB, we’re committed to supporting engineers and manufacturers with cutting-edge solutions for PCB design and fabrication. Whether you’re working on the next blockbuster console or a niche gaming device, choosing the right materials can make all the difference. Embrace the future of gaming hardware with advanced laminates and unlock the full potential of your designs.

ALLPCB

ALLPCB