In the fast-paced world of electronics manufacturing, ensuring the highest quality is non-negotiable. One critical method to achieve this is through X-ray inspection services, a powerful tool for detecting hidden defects in printed circuit boards (PCBs) and electronic components. But managing this process in-house can be costly and complex. That’s where outsourcing quality control with X-ray inspection services comes in as a game-changer. By partnering with specialized providers, manufacturers can save time, reduce costs, and maintain top-tier quality standards.

In this comprehensive guide, we’ll explore the benefits of outsourcing quality control for electronics manufacturing, dive into the role of X-ray inspection services, and explain why automated X-ray inspection (AXI) services are becoming a go-to solution for modern manufacturers. Whether you’re looking for electronics testing services or reliable X-ray service providers, this blog will provide actionable insights to help you make informed decisions.

What Are X-Ray Inspection Services and Why Are They Essential?

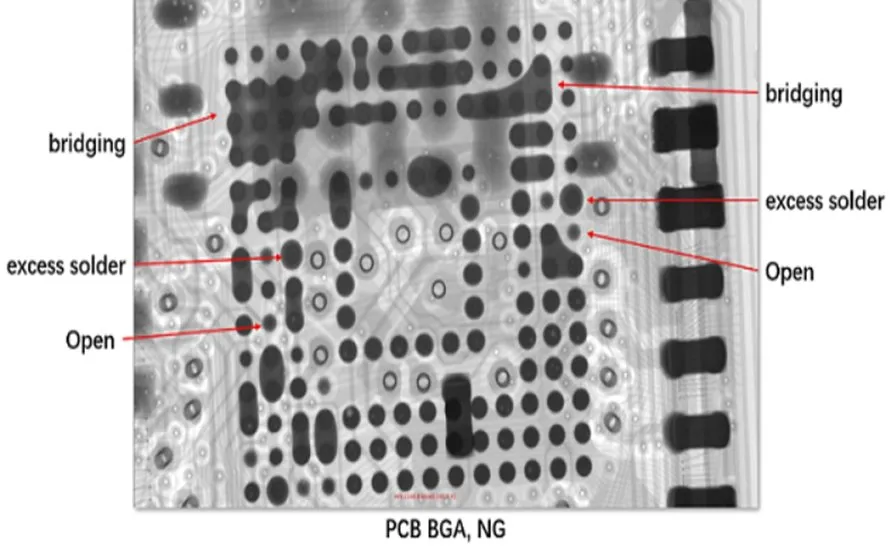

X-ray inspection services involve the use of advanced imaging technology to examine the internal structures of electronic components and assemblies without damaging them. Unlike traditional visual inspections, X-ray systems penetrate materials to reveal hidden issues such as solder joint defects, misaligned components, or internal cracks in PCBs. This non-destructive testing method is especially crucial for high-density boards with components like Ball Grid Arrays (BGAs), where pins are hidden beneath the package and cannot be inspected optically.

In electronics manufacturing, even a tiny defect can lead to product failure, costly recalls, or safety hazards. For instance, a poor solder joint in a BGA can cause intermittent connections, leading to device malfunctions. X-ray inspection services help detect such issues early, ensuring reliability and performance. As electronics become smaller and more complex, the demand for precise electronics testing services continues to grow, making X-ray inspection a cornerstone of quality control.

The Challenges of In-House Quality Control in Electronics Manufacturing

Maintaining an in-house quality control system for electronics manufacturing is no small feat. While it offers direct oversight, it comes with significant challenges:

- High Costs: Investing in X-ray inspection equipment can cost hundreds of thousands of dollars, not to mention ongoing maintenance and calibration expenses. For small to medium-sized manufacturers, this financial burden can be prohibitive.

- Specialized Expertise: Operating X-ray systems and interpreting results require trained technicians. Hiring or training staff for this purpose adds to operational costs and complexity.

- Scalability Issues: As production volumes fluctuate, in-house systems may struggle to keep up with demand or sit idle during low periods, leading to inefficient resource use.

- Regulatory Compliance: X-ray equipment involves strict safety and regulatory requirements. Ensuring compliance with local and international standards can be time-consuming and resource-intensive.

These challenges highlight why many manufacturers are turning to outsourcing quality control. By partnering with specialized X-ray service providers, companies can overcome these hurdles while focusing on their core competencies, such as design and production.

Benefits of Outsourcing Quality Control with X-Ray Inspection Services

Outsourcing quality control to professional X-ray service providers offers a range of advantages for electronics manufacturers. Let’s break down the key benefits:

1. Cost Efficiency

Outsourcing eliminates the need for upfront investments in expensive X-ray equipment and infrastructure. Instead, manufacturers pay for services as needed, turning a fixed cost into a variable one. This approach is particularly beneficial for smaller companies or those with fluctuating production needs. Additionally, outsourcing reduces labor costs associated with hiring and training specialized staff.

2. Access to Advanced Technology

X-ray service providers often invest in state-of-the-art automated X-ray inspection (AXI) systems that deliver superior accuracy and speed. These systems can detect defects with precision down to the micrometer level, ensuring even the smallest issues are caught. By outsourcing, manufacturers gain access to cutting-edge technology without the burden of ownership.

3. Expertise and Reliability

Professional providers of electronics testing services employ skilled technicians who specialize in X-ray analysis. Their expertise ensures accurate defect detection and detailed reporting, often with faster turnaround times than in-house teams can achieve. This reliability translates to fewer defective products reaching the market, protecting brand reputation.

4. Scalability and Flexibility

Outsourcing quality control allows manufacturers to scale testing efforts based on production volume. Whether you’re ramping up for a major product launch or scaling down during slower periods, X-ray service providers can adjust their services to match your needs. This flexibility ensures consistent quality without overcommitting resources.

5. Focus on Core Business Activities

By delegating quality control to external experts, manufacturers can focus on innovation, design, and production. This strategic shift enables companies to allocate internal resources more effectively, driving growth and competitiveness in the market.

Understanding Automated X-Ray Inspection (AXI) Services

Automated X-ray inspection (AXI) services represent the pinnacle of efficiency in electronics testing. Unlike manual X-ray inspection, which relies on human operators to analyze images, AXI uses advanced software and algorithms to automatically detect defects. This technology is particularly suited for high-volume production environments where speed and consistency are critical.

AXI systems can inspect thousands of components per hour, identifying issues such as solder voids, insufficient solder, or misaligned pins with over 99% accuracy, based on industry benchmarks. For example, in a typical BGA inspection, AXI can measure solder joint integrity by analyzing X-ray images for void percentages—voids above 25% often indicate potential reliability issues. This level of precision ensures that even subtle defects are caught before they impact performance.

Many X-ray service providers offer AXI as part of their portfolio, making it accessible to manufacturers who lack the resources to implement automated systems in-house. By leveraging AXI services, companies can achieve faster inspection cycles, reduce human error, and maintain consistent quality across large batches.

How to Choose the Right X-Ray Service Provider for Outsourcing Quality Control

Selecting the right partner for outsourcing quality control is crucial to achieving the desired results. Here are key factors to consider when evaluating X-ray service providers:

- Technical Capabilities: Ensure the provider offers advanced X-ray inspection services, including AXI capabilities for high-speed, automated testing. Check if their equipment can handle the specific requirements of your products, such as inspecting high-density PCBs or complex assemblies.

- Industry Experience: Look for providers with a proven track record in electronics manufacturing. Experience in your specific sector, whether automotive, medical, or consumer electronics, indicates a deeper understanding of relevant quality standards.

- Turnaround Time: Timely inspection is critical to maintaining production schedules. Choose a provider that offers fast yet accurate results, ideally with clear communication about expected delivery times.

- Reporting and Support: Opt for a provider that delivers detailed inspection reports with actionable insights. Bonus points if they offer support for root cause analysis to help address recurring defects.

- Compliance and Certifications: Verify that the provider adheres to industry standards such as IPC-A-610 for electronics assembly or ISO 9001 for quality management. Compliance with safety regulations for X-ray equipment is also essential.

By carefully evaluating potential partners, you can ensure a seamless outsourcing experience that enhances your quality control processes.

Applications of X-Ray Inspection Services in Electronics Manufacturing

X-ray inspection services play a vital role across various stages of electronics manufacturing. Here are some common applications:

- BGA and CSP Inspection: Ball Grid Arrays (BGAs) and Chip Scale Packages (CSPs) have hidden connections that are prone to defects like solder voids or bridging. X-ray inspection ensures these components meet quality standards.

- Through-Hole Component Verification: For assemblies with through-hole components, X-ray systems check for proper solder fill and alignment, preventing issues like insufficient bonding.

- Internal Defect Detection: X-ray services can identify internal cracks, delamination, or wire bond failures in components, which are invisible to optical inspection methods.

- Prototype Validation: During the prototyping phase, X-ray inspection helps validate design and assembly processes, reducing the risk of defects in mass production.

- Failure Analysis: When a product fails, X-ray inspection can pinpoint the root cause, whether it’s a manufacturing defect or a design flaw, enabling corrective action.

These applications demonstrate the versatility of X-ray inspection services in ensuring quality at every step of the manufacturing process.

The Future of Outsourcing Quality Control with X-Ray Inspection

As electronics manufacturing continues to evolve, the role of X-ray inspection services in quality control is set to expand. Emerging trends such as the integration of artificial intelligence (AI) with AXI systems are enhancing defect detection accuracy and speed. AI algorithms can analyze X-ray images in real-time, flagging anomalies with unprecedented precision—some systems report efficiency gains of up to 20 times compared to manual methods, as noted in industry discussions on social platforms.

Additionally, the growing complexity of electronics, driven by trends like 5G, IoT, and wearable devices, is increasing the demand for reliable electronics testing services. Outsourcing quality control to specialized X-ray service providers will likely become the norm for manufacturers seeking to stay competitive without bearing the full cost of in-house systems.

Furthermore, sustainability is becoming a priority. Outsourcing reduces the need for multiple companies to invest in energy-intensive X-ray equipment, lowering the overall environmental footprint of the industry. This alignment with green manufacturing practices adds another layer of value to partnering with external providers.

Conclusion: Why Outsourcing X-Ray Inspection Services Is a Smart Move

In the competitive landscape of electronics manufacturing, quality control is the foundation of success. X-ray inspection services offer an unparalleled way to detect hidden defects and ensure product reliability, but managing this process in-house can strain resources and focus. Outsourcing quality control to expert X-ray service providers addresses these challenges by delivering cost savings, access to advanced technology, and specialized expertise.

Whether you’re exploring AXI services for high-volume production or seeking reliable electronics testing services for a niche project, partnering with the right provider can transform your quality assurance strategy. By leveraging the benefits of outsourcing, manufacturers can maintain the highest standards, scale efficiently, and stay ahead in an ever-evolving industry.

At ALLPCB, we understand the importance of quality in electronics manufacturing. Our network of trusted partners offers cutting-edge X-ray inspection services to support your production needs. Embrace the power of outsourcing quality control and take your products to the next level with confidence.

ALLPCB

ALLPCB