Reverse polarity protection is a critical aspect of circuit design, ensuring that electronic devices are safeguarded against damage caused by incorrect power supply connections. One of the simplest and most effective ways to achieve this is by using a diode for preventing reverse current. But how do you choose the right diode for reverse polarity protection? This guide will walk you through the essential diode selection criteria, including diode voltage drop, diode current capacity, diode power dissipation, potential diode failure modes, and diode cost, helping you make an informed decision for your next project.

Why Reverse Polarity Protection Matters in Circuit Design

In any electronic system, connecting a power supply with reversed polarity—swapping positive and negative terminals—can lead to catastrophic damage. Components can overheat, burn out, or fail entirely, costing time and money to repair. A reverse polarity protection diode acts as a barrier, allowing current to flow in the correct direction while blocking it if the polarity is reversed. This simple addition can save your circuit from destruction, making diode selection a fundamental step for engineers.

In this comprehensive guide, we'll dive deep into the key factors that influence the choice of a diode for reverse polarity protection. Whether you're designing a small hobbyist project or a complex industrial system, understanding these criteria will ensure your circuit remains safe and efficient.

What Is a Reverse Polarity Protection Diode?

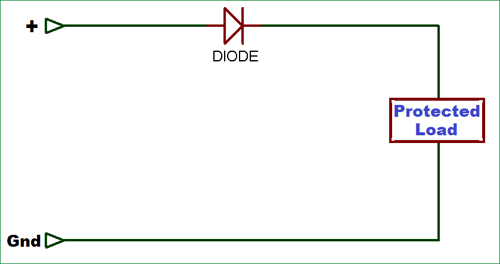

A reverse polarity protection diode is a semiconductor device placed in series with the power input of a circuit. Under normal conditions, the diode allows current to flow from the positive terminal of the power supply to the load. However, if the polarity is reversed, the diode becomes reverse-biased and prevents current from flowing, protecting the downstream components.

While this method is straightforward, selecting the right diode involves balancing several factors. A poorly chosen diode might introduce excessive voltage drop, overheat due to power dissipation, or fail under high current conditions. Let’s explore the critical diode selection criteria to avoid these pitfalls.

Key Diode Selection Criteria for Reverse Polarity Protection

1. Diode Voltage Drop: Minimizing Power Loss

One of the first factors to consider when choosing a diode for preventing reverse current is the forward voltage drop. This is the voltage lost across the diode when it conducts current. A standard silicon diode typically has a voltage drop of around 0.7V, while a Schottky diode, often preferred for reverse polarity protection, has a lower drop of about 0.2V to 0.3V at low currents.

Why does this matter? A high voltage drop reduces the voltage available to your circuit, potentially affecting performance, especially in low-voltage applications like 3.3V or 5V systems. Additionally, the voltage drop contributes to power loss, which we'll discuss later. For instance, in a 5V circuit with a 1A current draw, a silicon diode with a 0.7V drop results in a 0.7W power loss, whereas a Schottky diode with a 0.3V drop reduces this to 0.3W—a significant difference in efficiency.

When selecting a diode, prioritize low voltage drop options like Schottky diodes if your application is sensitive to power loss or operates at low voltages. However, be aware that Schottky diodes often have higher leakage currents in reverse bias, which might be a concern in some designs.

2. Diode Current Capacity: Handling the Load

The diode current capacity, or the maximum forward current it can handle, is another crucial factor. This rating must exceed the maximum current your circuit will draw under normal operation. If the diode’s current rating is too low, it can overheat and fail, leading to potential damage to the entire system.

For example, if your circuit draws a peak current of 2A, you should select a diode with a current rating of at least 3A to provide a safety margin. Common diodes like the 1N4001 series are rated for 1A, while higher-capacity options like the 1N5400 series can handle up to 3A. For even higher currents, consider power diodes or Schottky diodes rated for 5A, 10A, or more, depending on your needs.

Always check the diode’s datasheet for its continuous forward current rating and ensure it aligns with your circuit’s requirements. It’s also wise to derate the diode—choosing one with a rating 20-50% higher than needed—to account for transient spikes or unexpected load increases.

3. Diode Power Dissipation: Managing Heat

Diode power dissipation is directly tied to the forward voltage drop and the current flowing through it. The power dissipated by a diode is calculated as P = Vf × If, where Vf is the forward voltage drop and If is the forward current. Excessive power dissipation leads to heat buildup, which can degrade the diode’s performance or cause thermal failure.

Consider a scenario where a diode with a 0.7V drop handles a 2A current. The power dissipation is 1.4W (0.7V × 2A). If the diode isn’t mounted on a heat sink or lacks proper ventilation, this heat can raise its junction temperature beyond the maximum rating (often around 125°C to 150°C for standard diodes), leading to failure.

To manage diode power dissipation, select a diode with a low voltage drop for high-current applications, as this minimizes heat generation. Additionally, check the diode’s thermal resistance and maximum junction temperature in the datasheet. If necessary, use a heat sink or choose a diode package designed for better heat dissipation, such as TO-220 or SMD packages with thermal pads.

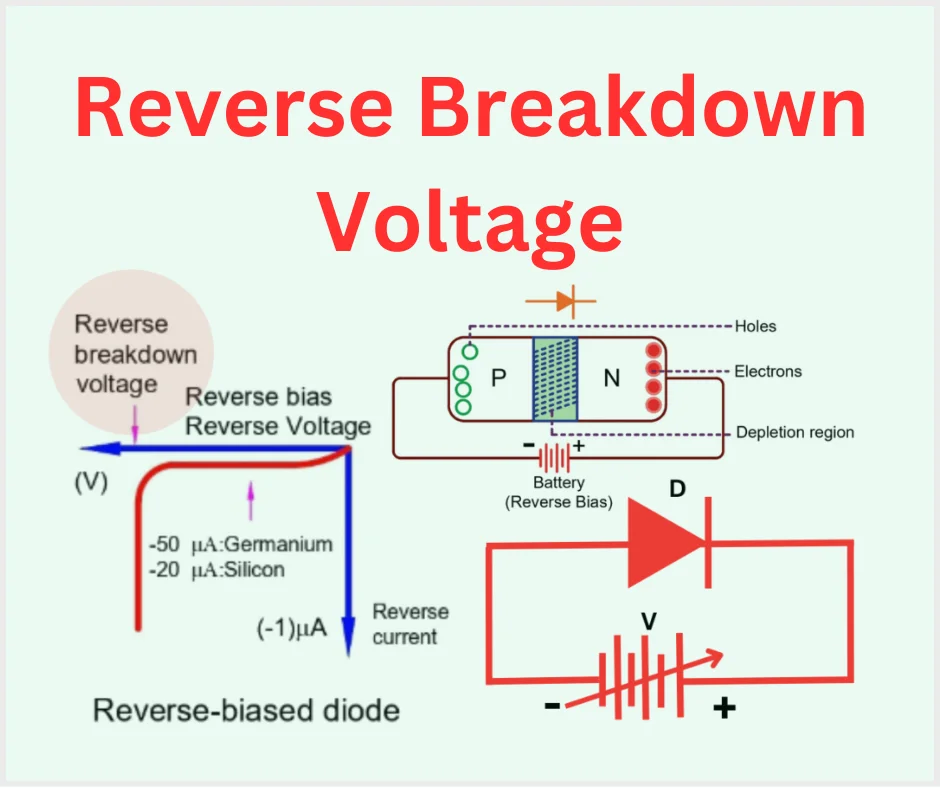

4. Reverse Voltage Rating: Ensuring Safety

The reverse voltage rating, or Peak Inverse Voltage (PIV), of a diode indicates the maximum voltage it can withstand when reverse-biased without breaking down. For reverse polarity protection, this rating must be higher than the maximum input voltage your circuit might encounter, including any potential transients or spikes.

For instance, in a 12V system, a diode with a PIV of at least 20V is recommended to account for voltage surges. A common choice like the 1N4002 has a PIV of 100V, providing ample margin for most low-voltage applications. However, in automotive systems where voltages can spike to 40V or more during load dumps, a diode with a PIV of 50V or higher is essential.

Always consult the datasheet for the PIV rating and ensure it exceeds your system’s maximum possible voltage to prevent diode breakdown during reverse polarity events.

5. Diode Failure Modes: Anticipating Risks

Understanding potential diode failure modes is vital to designing a reliable circuit. Diodes can fail in several ways when used for reverse polarity protection:

- Thermal Failure: Excessive power dissipation can overheat the diode, causing it to fail. This is common when current capacity or heat dissipation isn’t adequately managed.

- Reverse Breakdown: If the reverse voltage exceeds the PIV rating, the diode can suffer permanent damage, allowing current to flow in the wrong direction and potentially harming the circuit.

- Current Surge Damage: A sudden inrush of current beyond the diode’s surge rating can cause it to fail. Check the diode’s forward surge current rating in the datasheet to ensure it can handle startup transients.

To mitigate these risks, select a diode with appropriate ratings for current, voltage, and power dissipation. Additionally, consider adding transient voltage suppressors or fuses in parallel with the diode for extra protection against surges.

6. Diode Cost: Balancing Performance and Budget

Finally, diode cost plays a role in the selection process, especially for large-scale production or budget-conscious projects. Standard silicon diodes like the 1N4001 are incredibly affordable, often costing less than $0.10 per unit in bulk. Schottky diodes, while offering lower voltage drops, can cost slightly more, ranging from $0.20 to $1.00 depending on current and voltage ratings.

For most applications, the cost difference is negligible compared to the potential savings from preventing circuit damage. However, in high-volume designs, even a small price difference per unit can add up. Evaluate whether the benefits of a premium diode (e.g., lower voltage drop or higher current capacity) justify the added expense for your specific use case.

Types of Diodes for Reverse Polarity Protection

Not all diodes are created equal for reverse polarity protection. Here are the two most common types and their trade-offs:

- Silicon Diodes: These are the most common and cost-effective option, with a typical voltage drop of 0.6V to 0.7V. They are suitable for applications where efficiency isn’t a primary concern and currents are moderate.

- Schottky Diodes: Known for their low voltage drop (0.2V to 0.3V), Schottky diodes are ideal for low-voltage or high-efficiency applications. However, they may have higher reverse leakage current and cost more than silicon diodes.

Choose the type based on your circuit’s voltage, current, and efficiency requirements. For high-current or low-voltage systems, Schottky diodes are often the better choice despite the higher cost.

Practical Tips for Implementing Reverse Polarity Protection

Beyond selecting the right diode, consider these practical tips to ensure effective protection:

- Placement: Place the diode as close to the power input as possible to protect all downstream components.

- Heat Management: Use a heat sink or ensure proper PCB layout for heat dissipation if the diode handles high currents.

- Alternative Solutions: In high-current applications where diode voltage drop is unacceptable, consider using a P-channel MOSFET for reverse polarity protection. This approach minimizes voltage loss but adds complexity and cost.

Conclusion: Choosing the Right Diode for Your Needs

Selecting the right diode for reverse polarity protection is a balance of technical requirements and practical considerations. By focusing on diode voltage drop, diode current capacity, diode power dissipation, reverse voltage rating, potential diode failure modes, and diode cost, you can ensure your circuit is both safe and efficient. Whether you opt for a low-cost silicon diode or a high-efficiency Schottky diode, always refer to the datasheet for detailed specifications and derate where necessary to build in a safety margin.

At ALLPCB, we understand the importance of reliable components in your designs. By applying the diode selection criteria outlined in this guide, you can protect your circuits from the risks of reverse polarity and achieve long-lasting performance in your projects.

ALLPCB

ALLPCB