With the rapid development of modern electronics and information industries, electronic components and assemblies require higher computing and transmission performance and are trending toward higher frequency and higher speed. For example, smartphones now commonly include photography, video playback, data transfer, Wi?Fi, fingerprint recognition, positioning, and accelerometers in addition to voice calls. The trend toward higher frequency and higher speed in components is expected to become more pronounced.

Driven by higher frequencies and speeds, EMI shielding film can effectively suppress electromagnetic interference (EMI) and reduce signal attenuation and integrity issues.

As the electronics and information industry develops, demand for electromagnetic shielding in electronic products is expanding.

NO.1 What is EMI Shielding Film?

To understand what EMI shielding film is, first consider electromagnetic shielding.

Electromagnetic shielding (EMC) is a method that uses a shield made from special materials to confine electromagnetic waves within a defined area, suppressing or attenuating electromagnetic radiation. It is an effective way to reduce electromagnetic interference.

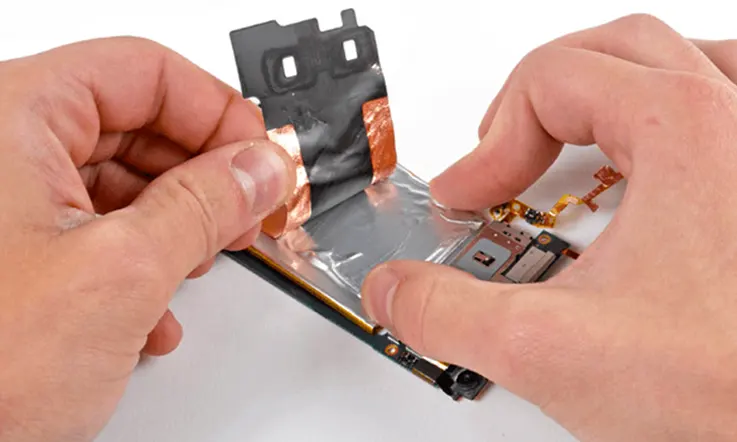

EMI shielding film is a protective film that provides electromagnetic shielding.

EMI shielding film is applied directly to flexible printed circuits (FPC). In the context of rapid development of smartphones, wearable devices, and automotive electronics, FPC demand has increased quickly and the market opportunity for EMI shielding film has expanded. At the same time, the use of electronic components has grown substantially with the proliferation of electronic products, making electromagnetic interference more severe and increasing demand for shielding. As a key EMI shielding material for FPCs, demand for shielding film has continued to grow.

NO.2 Industry Chain of EMI Shielding Film

The upstream of the EMI shielding film industry includes chemical raw materials such as conductive particles and polyester film. The downstream is mainly FPC manufacturers, and the industry is relatively concentrated. EMI shielding film sits in the midstream of the FPC supply chain. Midstream participants are the shielding film manufacturers; market participants are relatively few, and leading companies have large capacity. Two major players, a Japanese firm Tuozhida and China’s Fangbang Co., Ltd., account for about 70% of the China market share.

NO.3 Three Drivers of EMI Shielding Film Growth

1. Growth of end?market applications

The factors driving end?market growth are primarily the development of the FPC market, consumer electronics, and automotive electronics.

FPC market

Flexible printed circuits offer high wiring density, small size, light weight, and bendability, making them essential for multifunctional, miniaturized, and portable electronic products. EMI shielding film is a core material that enables FPCs to achieve electromagnetic shielding and ensure normal operation. Growth in consumer electronics and automotive electronics drives FPC demand, which in turn supports a favorable market environment for EMI shielding film.

Consumer electronics

It is estimated that by 2025 the global FPC market for wearable devices will reach 11.4 billion USD, with wireless earbuds and smartwatches taking the largest shares.

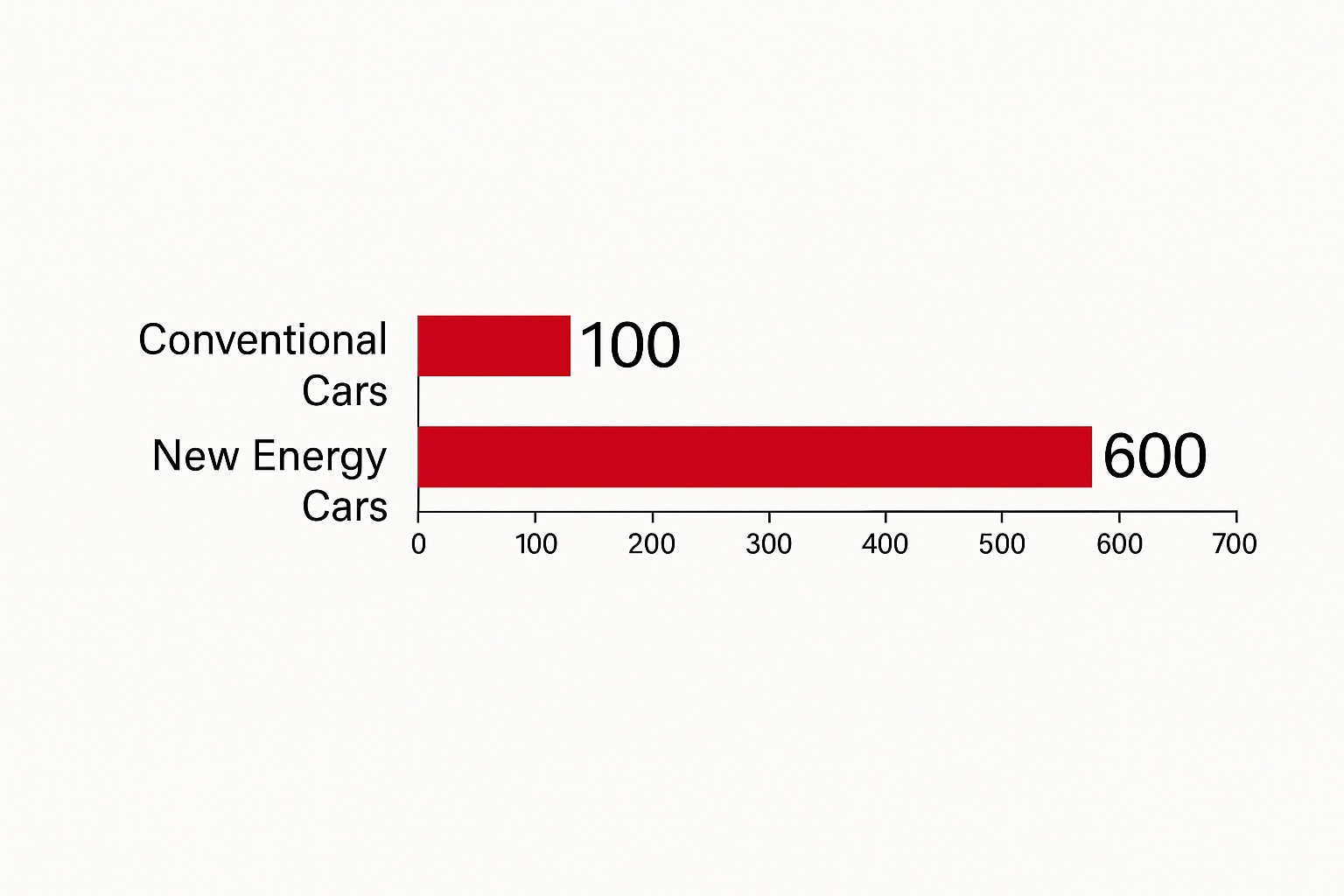

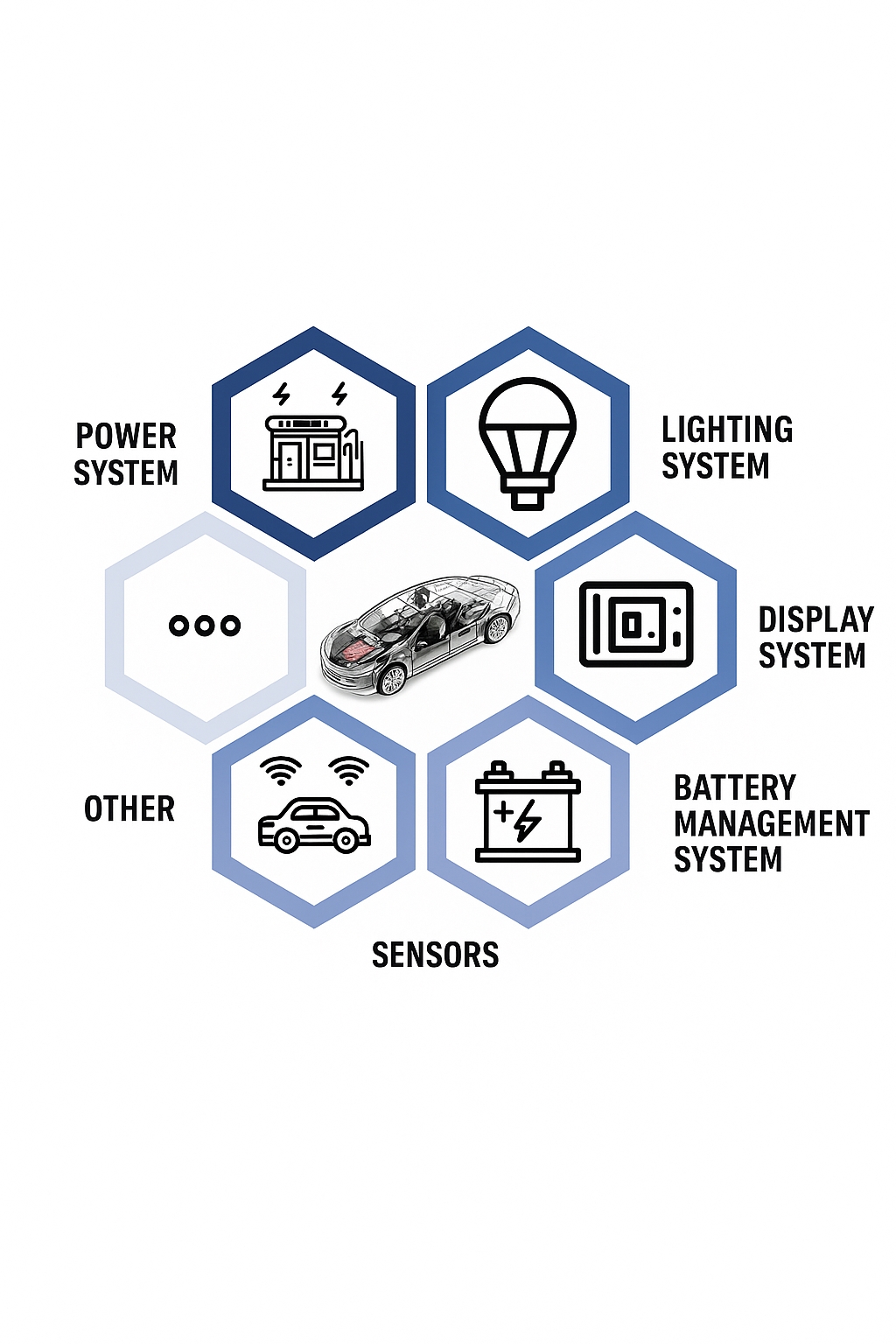

Automotive electronics

With the rapid development of new energy vehicles and higher levels of vehicle intelligence, demand for electronic components in lighting, displays, power systems, battery management systems, and sensors has increased. Automotive FPCs are being used more widely due to advantages such as light weight and simpler structure. While traditional vehicles use about 100 FPC pieces, new energy vehicles may require 5 to 8 times that amount.

New energy vehicles have been identified as a strategic emerging industry in national development plans, and the market size is expected to continue growing. In 2018, automotive FPC accounted for 7% of global FPC market size. Given the expected rapid growth of the global new energy vehicle market over the next decade, the automotive FPC market is forecast to reach 2.4 billion USD by 2030.

2. Global FPC capacity shifting to China

The FPC industry has high concentration, with major manufacturers based in Japan, South Korea, and Taiwan. Mainland China manufacturers previously held a smaller share but are now maintaining rapid growth, reflecting a global shift of FPC production capacity toward China.

3. 5G deployment

Since large?scale 5G licensing and deployment began, the development of 5G communication networks and related infrastructure has accelerated, creating opportunities for EMI shielding film.

To address signal attenuation, 5G networks use Massive MIMO technology, which compensates for attenuation by greatly increasing the number of antennas. Compared with 4G, the number of antennas in 5G base stations and user devices has increased by multiples—from 2, 4, or 8 up to 16, 64, 128, or even 256—raising requirements for electromagnetic immunity and increasing demand for shielding solutions.

ALLPCB

ALLPCB