Overview

The high-precision vibration sensor uses industrial-grade sensing technology and intelligent diagnostic algorithms for real-time motor condition monitoring. This article links common motor fault signatures with industry requirements and explains the technical advantages and application outcomes of vibration sensors in predictive maintenance.

Motor monitoring pain points and core value of vibration sensors

Motors are core power units in industrial systems and, during long-term operation, are prone to vibration anomalies caused by bearing wear, rotor imbalance, shaft misalignment, and similar issues. Traditional manual inspection relies on periodic spot checks or listening devices, which are subjective, low frequency, and produce delayed data. Such methods struggle to capture high-frequency vibration or micron-level deformation features, resulting in late fault detection and potential unplanned downtime. Vibration sensors convert mechanical vibration into electrical signals (for example, acceleration or velocity), enabling real-time data collection at key locations such as bearing housings and casings, and facilitating a shift from reactive maintenance to early warning. Core values include:

- Continuous monitoring: automatic data capture at minute-level intervals to avoid blind spots of manual inspection.

- Multi-dimensional diagnosis: three-axis synchronous measurement (X/Y/Z) accurately distinguishes radial, axial, and tangential vibration energy distributions, providing a comprehensive view of equipment health.

Technical characteristics and operational adaptation

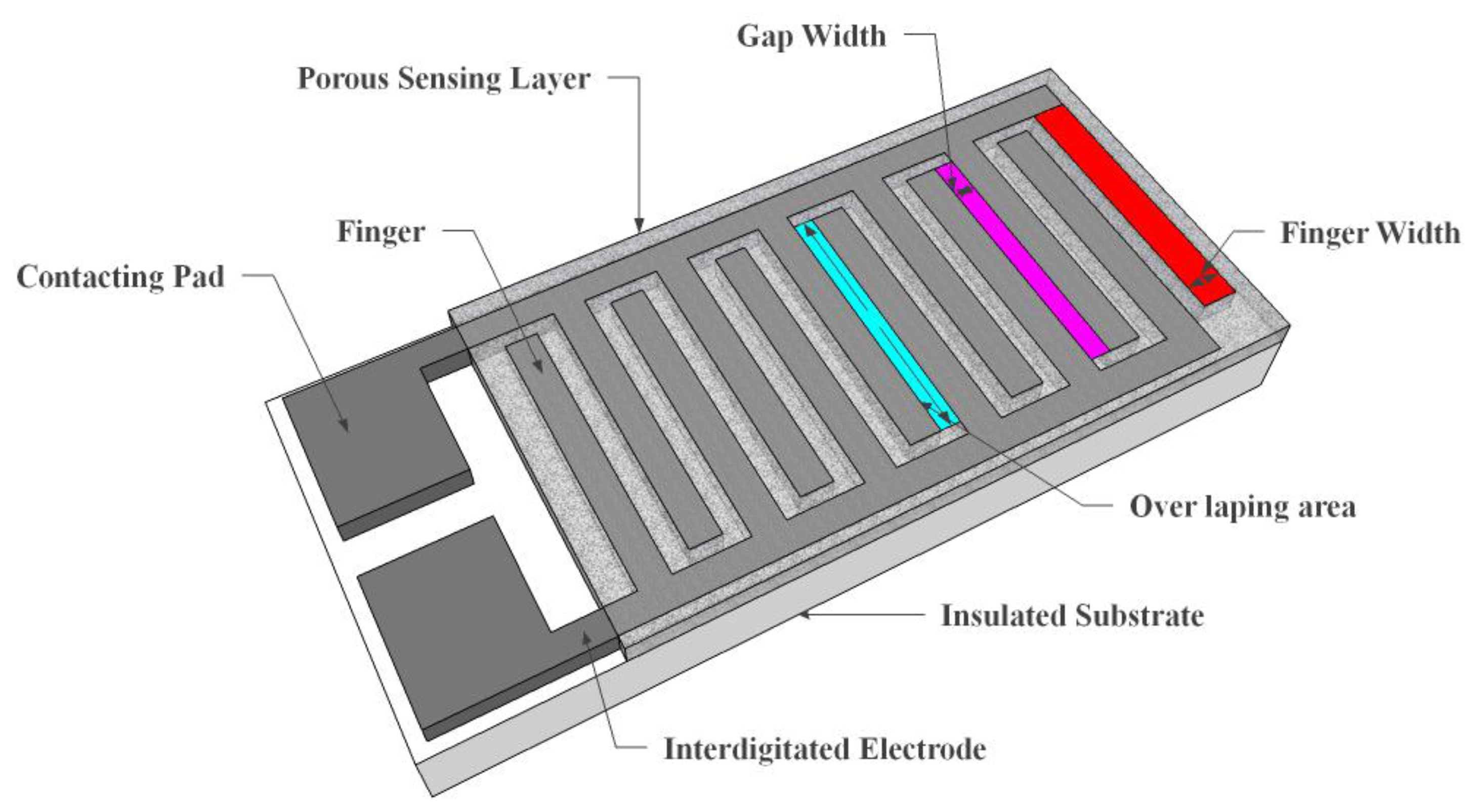

1. High-precision measurement and interference resistance

The sensor uses MEMS or piezoelectric sensing principles and can achieve an accuracy of approximately ±5% of full scale. It can detect high-frequency resonances caused by bearing damage (for example, inner-race spall frequencies) or 2X rotational frequency peaks from rotor misalignment. For high-temperature, high-humidity, or dusty environments, the sensor is housed to IP67 protection and designed for a wide temperature range (-40°C to 85°C). Internal temperature compensation algorithms reduce thermal drift and help ensure data reliability.

2. Intelligent diagnostics and system integration

Onboard algorithms can filter electromagnetic noise and short-term load fluctuations, focusing on long-term trend analysis. With configurable multi-stage thresholds, the system can generate alerts when vibration levels exceed limits or when trends change abruptly. Data can be sent to a mobile device or monitoring platform and supports historical data review. Measurement data can be output via 4-20 mA current signals or communicated over Modbus or MQTT to PLC or SCADA systems for integration with existing control architectures.

3. Wireless transmission and low-power design

In remote sites such as wind farms or mines, the sensor can use low-power wireless protocols such as NB-IoT or LoRa. Intelligent power management enables multi-year operation on battery power, typically 3-5 years, reducing cabling complexity and deployment cost.

Application scenarios and validation

1. Early detection of bearing wear

Early-stage bearing faults generate high-frequency impact signals that traditional methods may miss. Vibration sensors use envelope spectrum analysis to extract weak impact features and apply trend models to estimate remaining useful life. For example, in a wind power project, detecting an abnormal 48 Hz harmonic helped diagnose gearbox tooth surface wear and supported maintenance decision-making.

2. Rotor imbalance and misalignment diagnosis

Rotor imbalance typically appears as an increase in the 1X rotational frequency amplitude, while shaft misalignment shows up as a 2X rotational frequency peak. Three-axis sensors can capture multi-directional vibration energy synchronously to localize the fault source. In one case, sensors recorded a weekly growth rate of 20% in the 2X rotational peak; inspection confirmed a 0.2 mm offset on the coupling mounting face, and after correction the vibration amplitude decreased by 60%.

3. Adaptation in heavy industry and energy sectors

In heavy-duty environments such as rolling mills and mining crushers, sensors must be impact resistant and corrosion resistant. In wind turbines, long-term trend monitoring, for example an annual vibration amplitude increase of 5%, can be used to schedule periodic maintenance and reduce unexpected shutdowns by a substantial margin.

ALLPCB

ALLPCB