If you're a PCB designer searching for the right surface finish, you might be weighing the benefits and drawbacks of immersion tin. In short, immersion tin offers excellent solderability and surface flatness at a low cost, making it ideal for fine-pitch components. However, it comes with challenges like short storage time, risk of tin whisker formation, and limited soldering reliability for long-term or high-stress applications. In this comprehensive guide, we'll dive deep into the pros and cons of immersion tin, explore key PCB design considerations, and help you decide if this finish suits your project needs.

What Is Immersion Tin and Why Does It Matter in PCB Design?

Immersion tin, often called white tin, is a surface finish applied to printed circuit boards (PCBs) through an electroless chemical process. This method deposits a thin layer of tin onto the exposed copper traces, pads, and vias of a PCB, protecting them from oxidation and ensuring they remain solderable. Unlike other finishes like HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold), immersion tin is a cost-effective option that provides a flat surface, which is crucial for modern, high-density designs.

For PCB designers, choosing the right surface finish is a critical decision. It impacts not just the manufacturing cost but also the board's performance, reliability, and assembly process. Immersion tin has gained popularity in applications like consumer electronics and prototyping due to its affordability and compatibility with lead-free soldering. But is it the right choice for every project? Let's break down the immersion tin pros and cons to give you a clear picture.

The Pros of Immersion Tin in PCB Design

Immersion tin offers several advantages that make it a go-to choice for many PCB designers, especially in cost-sensitive or fine-pitch applications. Here are the key benefits:

1. Excellent Solderability for Assembly

One of the standout features of immersion tin is its superior solderability. The tin layer forms a strong bond with solder during assembly, ensuring reliable joints. This is particularly important in lead-free soldering processes, which are now standard due to environmental regulations like RoHS. Immersion tin performs well under multiple reflow cycles (up to 3 cycles are generally recommended), making it suitable for surface-mount technology (SMT) assembly with components like BGAs and QFPs.

2. Superior Surface Flatness for Fine-Pitch Components

Surface flatness is a critical factor in PCB design, especially for high-density boards with fine-pitch components (e.g., pitch sizes below 0.5 mm). Immersion tin provides a uniformly flat surface, unlike HASL, which can result in uneven solder bumps. This flatness ensures better contact during assembly, reducing the risk of defects like tombstoning or misalignment. For designers working on compact devices like smartphones or IoT modules, this is a significant advantage.

3. Cost-Effective Solution for Budget-Conscious Projects

Compared to premium finishes like ENIG, immersion tin is more affordable, often costing 20-30% less depending on the manufacturer and board specifications. This makes it an attractive option for prototyping, consumer electronics, and other applications where budget constraints are a priority. If you're designing a board for a short product lifecycle or a low-cost device, immersion tin can help keep expenses down without sacrificing basic performance.

4. Compatibility with Lead-Free Processes

Immersion tin aligns well with lead-free soldering requirements. The tin layer withstands the higher temperatures (typically around 260°C) associated with lead-free solder alloys like SAC305 (Sn-Ag-Cu). This compatibility ensures that designers can meet regulatory standards while maintaining assembly quality.

The Cons of Immersion Tin in PCB Design

While immersion tin has notable benefits, it also comes with limitations that PCB designers must consider. Understanding these drawbacks will help you make an informed decision for your specific application.

1. Short Storage Time Due to Oxidation Risk

One of the biggest challenges with immersion tin is its limited shelf life. The tin layer is prone to oxidation when exposed to air and humidity, especially if stored for more than 6-12 months. Once oxidized, the surface loses its solderability, leading to poor assembly results. To mitigate this, PCBs with immersion tin must be stored in a cool, dry environment with humidity below 50%. This short storage time can be a significant drawback for projects with long lead times or inventory delays.

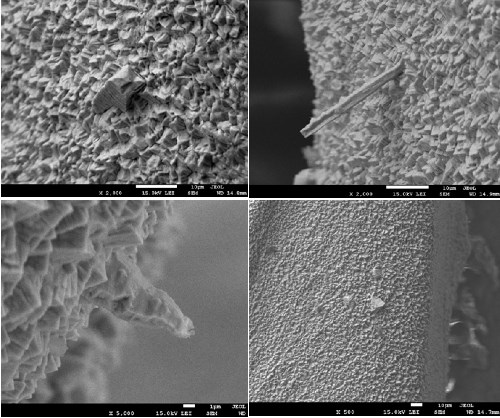

2. Risk of Tin Whisker Formation

Tin whisker formation is a well-documented issue with pure tin finishes like immersion tin. These are tiny, hair-like growths of tin that can form over time due to internal stress in the tin layer. Whiskers can grow to lengths of 1-5 mm or more, potentially causing short circuits if they bridge adjacent traces or pads. This risk is particularly concerning for high-reliability applications like aerospace or medical devices, where even a single failure can be catastrophic. While mitigation strategies like conformal coating can help, they add to the overall cost and complexity.

3. Limited Soldering Reliability for High-Stress Applications

Although immersion tin offers good initial solderability, its long-term soldering reliability is not as robust as other finishes like ENIG. Over time, intermetallic compounds (IMCs) form between the tin and underlying copper, which can weaken solder joints. Studies suggest that after 1000 thermal cycles (e.g., -40°C to 85°C), immersion tin joints may show a 15-20% higher failure rate compared to gold-based finishes. This makes it less suitable for applications exposed to thermal or mechanical stress, such as automotive electronics.

4. Sensitivity to Handling and Environmental Conditions

Immersion tin surfaces are delicate and can be easily damaged by fingerprints, scratches, or contamination during handling. Such damage can compromise solderability and lead to assembly defects. Additionally, the finish is sensitive to environmental factors like humidity and temperature, requiring strict storage and handling protocols. For designers working in less controlled environments, this can pose logistical challenges.

Key PCB Design Considerations for Immersion Tin

When considering immersion tin for your PCB design, several factors beyond the basic pros and cons come into play. Addressing these considerations early in the design phase can help you avoid costly mistakes and ensure optimal performance.

1. Application and Reliability Requirements

First, evaluate the end-use application of your PCB. Is it for a low-cost consumer gadget with a short lifecycle, or a high-reliability system like a satellite or medical device? Immersion tin is best suited for applications where cost and surface flatness are priorities, and long-term reliability is less critical. For high-stress environments, consider alternatives with better durability, even if they come at a higher cost.

2. Storage and Assembly Timeline

Given the short storage time of immersion tin, plan your manufacturing and assembly timeline carefully. If your project involves long delays between PCB fabrication and assembly, ensure proper storage conditions or opt for a finish with a longer shelf life. For example, storing boards at temperatures below 25°C and humidity below 50% can extend usability up to 12 months.

3. Component Density and Pitch

Immersion tin shines in designs with fine-pitch components due to its flat surface. If your design includes components with pitches below 0.5 mm, such as 0201 resistors or micro BGAs, immersion tin can help ensure precise placement and soldering. However, conduct soldering tests to verify compatibility, as variations in tin thickness (typically 0.8-1.2 μm per IPC-4554 standards) can affect results.

4. Mitigation of Tin Whisker Risks

To minimize the risk of tin whisker formation, consider design strategies like increasing trace spacing (e.g., above 0.3 mm) to reduce the chance of shorts. Additionally, applying a conformal coating after assembly can act as a barrier against whisker growth, though this adds an extra step and cost to the process. Weigh these factors against the project budget and reliability needs.

How Does Immersion Tin Compare to Other Surface Finishes?

To provide a balanced perspective, it's helpful to compare immersion tin with other common PCB surface finishes. Here's a quick overview focusing on key metrics like cost, solderability, and reliability:

- Cost: Immersion tin is cheaper than gold-based finishes (20-30% less expensive) but slightly more expensive than traditional HASL.

- Solderability: It offers excellent initial solderability, comparable to HASL, but not as durable over time as gold finishes.

- Surface Flatness: Immersion tin provides better flatness than HASL, making it more suitable for fine-pitch designs, though it matches silver-based finishes in this regard.

- Reliability: It lags behind gold finishes in long-term reliability due to IMC formation and whisker risks, making it less ideal for critical applications.

This comparison highlights that immersion tin strikes a balance between cost and performance, fitting well for specific use cases but not universally.

Practical Tips for Using Immersion Tin in Your PCB Designs

If you decide to use immersion tin for your next project, here are some actionable tips to maximize its benefits and minimize its drawbacks:

- Optimize Storage Conditions: Store PCBs in a controlled environment with low humidity (below 50%) and temperature (below 25°C) to prevent oxidation.

- Limit Reflow Cycles: Design your assembly process to keep reflow cycles under 3 to avoid degrading the tin layer.

- Handle with Care: Use gloves and clean tools during handling to prevent contamination or scratches on the tin surface.

- Test Solderability: Before full-scale production, conduct soldering tests, especially for fine-pitch components, to ensure consistent results.

- Consider Alternatives for High Reliability: If your application demands long-term durability, evaluate other finishes despite the higher cost.

Conclusion: Is Immersion Tin Right for Your PCB Design?

Immersion tin offers a compelling mix of affordability, solderability, and surface flatness, making it a strong choice for cost-sensitive projects and designs with fine-pitch components. However, its limitations, such as short storage time, risk of tin whisker formation, and reduced soldering reliability over time, mean it's not ideal for every application. By carefully considering your project's requirements, timeline, and environmental conditions, you can determine if immersion tin aligns with your needs.

For PCB designers, understanding these immersion tin pros and cons is just the starting point. Dive into the specific PCB design considerations, from storage protocols to assembly testing, to ensure success. Whether you're working on a prototype or a high-volume consumer product, this balanced perspective can guide you toward the best surface finish for your design goals.

ALLPCB

ALLPCB