Overview

In high-temperature, high-vibration environments such as vehicle engine compartments and complex operating conditions in construction machinery, accurate transmission of critical data like pressure, rotational speed, and temperature directly determines ECU control accuracy and equipment safety. Hongke PSI5 sensors, as products based on the PSI5 protocol, provide an application-level solution to this requirement.

What is PSI5?

PSI5 (Peripheral Sensor Interface 5) is a short-range serial communication protocol used in automotive and industrial applications, focused on synchronous data transfer between safety-relevant sensors and ECUs. Its value lies not only in hardware connectivity but also in standardized programming that enables efficient dialogue between sensors and controllers.

Key characteristics

- Strong interference immunity: suitable for high temperatures, vibration, and electromagnetic interference

- Precise synchronization: ensures time consistency across multiple sensors

- Supports multiple slaves: can connect multiple sensors simultaneously to simplify wiring

- ISO 26262 compliance: meets requirements for automotive safety-related applications

Typical applications

As a sensor-dedicated bus, PSI5 is used across automotive core systems and specialized industrial scenarios, covering critical safety and control functions.

Automotive safety systems

- Steering angle sensors: provide precise angle data for electric power steering systems

- Acceleration sensors: support real-time state sensing for vehicle stability systems

- Pressure sensors: monitor brake system pressure to ensure braking safety

Powertrain systems

- Crankshaft position sensors: enable precise control of ignition timing

- Camshaft position sensors: support refined fuel injection control

- Transmission speed sensors: match shift logic and improve transmission efficiency

Chassis systems

- Tire pressure monitoring sensors: real-time monitoring to reduce blowout risk

- Chassis attitude sensors: report stability status to optimize chassis control strategies

Other specialized scenarios

- Construction machinery: reliable transmission of hydraulic safety sensor data

- Special-purpose vehicles: status monitoring sensors that meet automotive-grade interference requirements

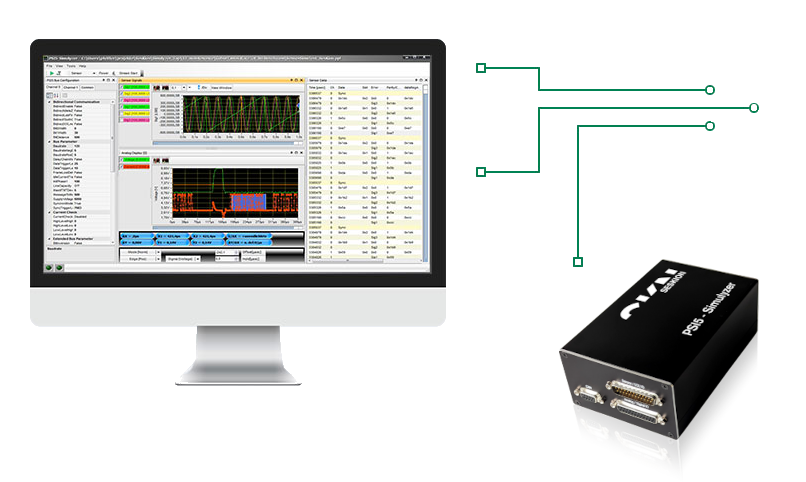

Hongke PSI5 Sensor

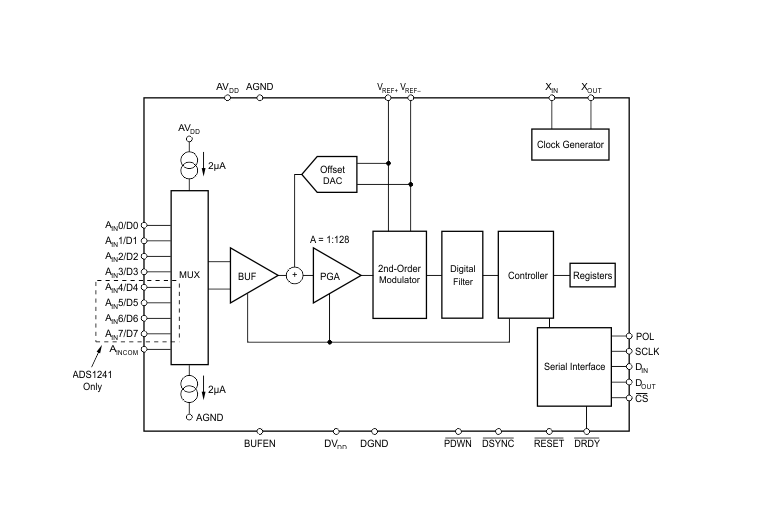

Provides USB 2.0 interface and interfaces for connecting control units and sensors. Power is supplied via an external connector power device. Compatible with Windows 10 and 11, Microsoft .NET Framework 2.0, and Linux (only A PI, no GUI). Supports recording PSI5 voltage and current at up to 3 Ms/s. Data export is supported in .csv (Excel) and .tdms (NI) formats. Standardized data rates include 125 and 189 kbit/s, with single data rate range of 80–250 kbit/s. Supports all operating modes as defined by the PSI5 specification.

Programming Diagnostic Mode on Hongke PSI5 Sensors

Diagnostic mode for Hongke PSI5 sensors must be activated using manufacturer-defined logic (it is not standardized). To set a sensor into diagnostic mode, data within the manufacturer-defined addressing range must be supplied. Diagnostic mode is activated by a specific data sequence sent from the ECU to the sensor. The following outlines the procedure using a PSI5-P10P-500-3L sensor as an example (NXP-MMA52xxKW family).

ECU mode initialization

Set the ECU mode to power to begin measurements.

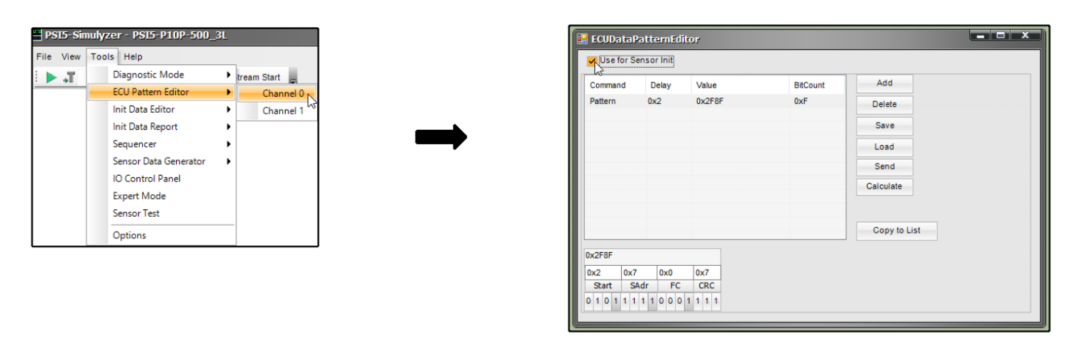

Programming mode parameter configuration (core step)

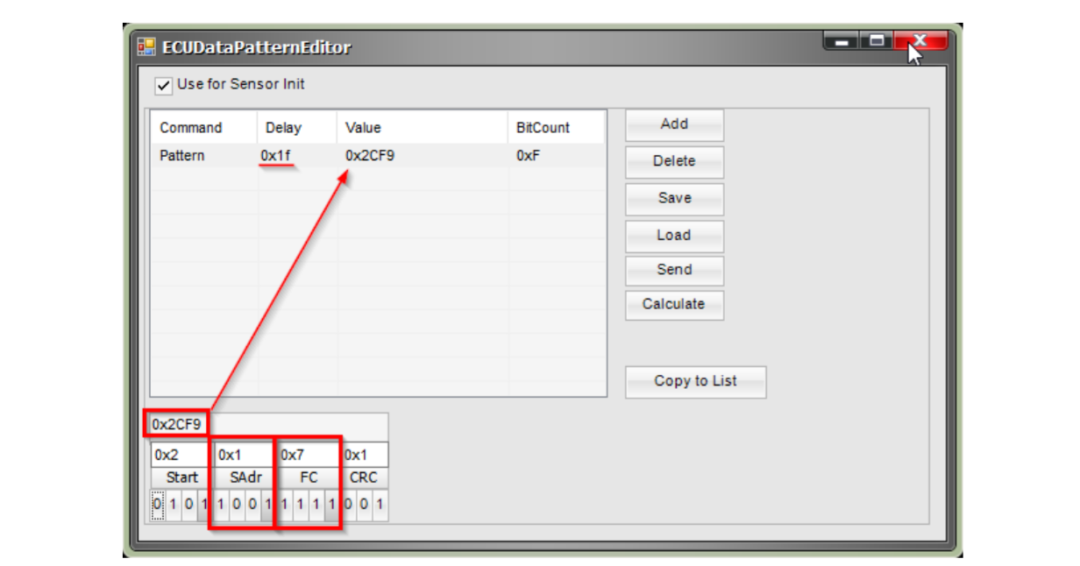

Enter the ECU data mode editor and set delay and value fields correctly.

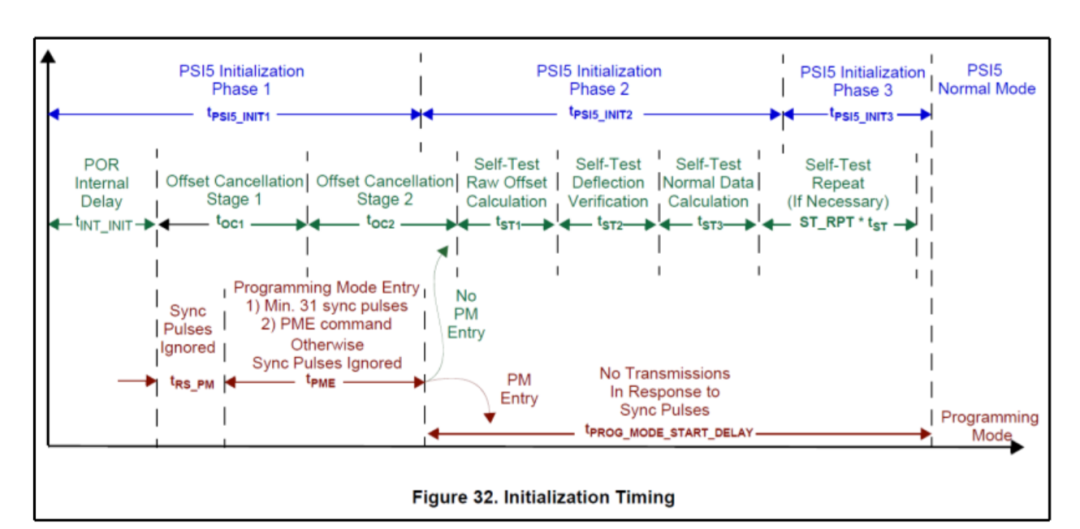

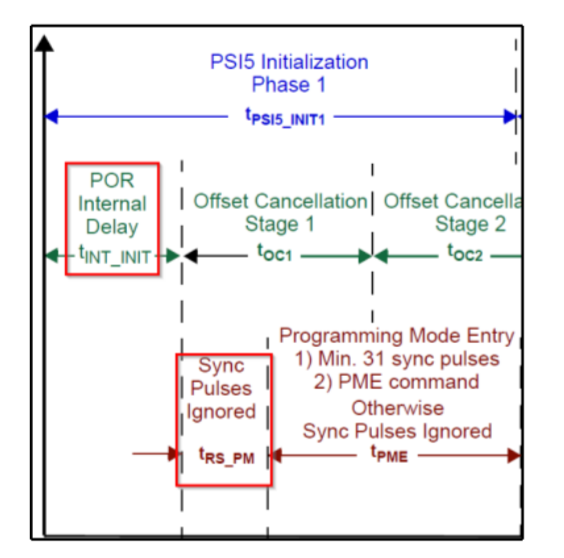

Delay setting: Delay values and setting methods are shown in the Hongke PSI5 sensor data sheet diagrams. The delay must be at least 31 synchronization pulse lengths. Thirty-one corresponds to hexadecimal 0x1F, so enter 0x1F in the delay field.

Value conversion and entry: Parameter values are typically listed in hexadecimal and must be converted to decimal for entry where required. In this example, SAdr decimal is 1 and FC decimal is 7. Enter the corresponding values in the ECU mode editor. The final value becomes 0x2CF9 (including CRC, SAdr, FC, and other core fields).

Key parameter calculation: To enter programming mode, read POR Internal Delay (power-on reset internal delay) and Sync Pulses Ignored from the data sheet. The sum of these values is the core delay reference.

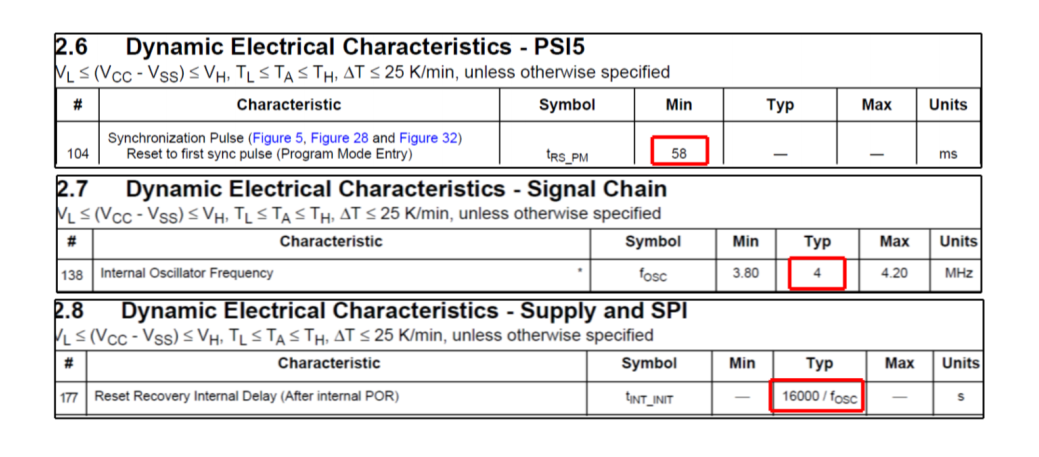

Specific parameter verification: In this demonstration, the sensor specifies sync pulses of at least 58 ms. The sensor internal oscillator frequency fosc is 4 MHz, which corresponds to 0.00025 ms per cycle. Using the data sheet formula Reset Recovery Internal Delay (tINT_INIT) = 16000 / fosc, the internal delay computes to a total delay of 62 ms.

Frame format selection and configuration

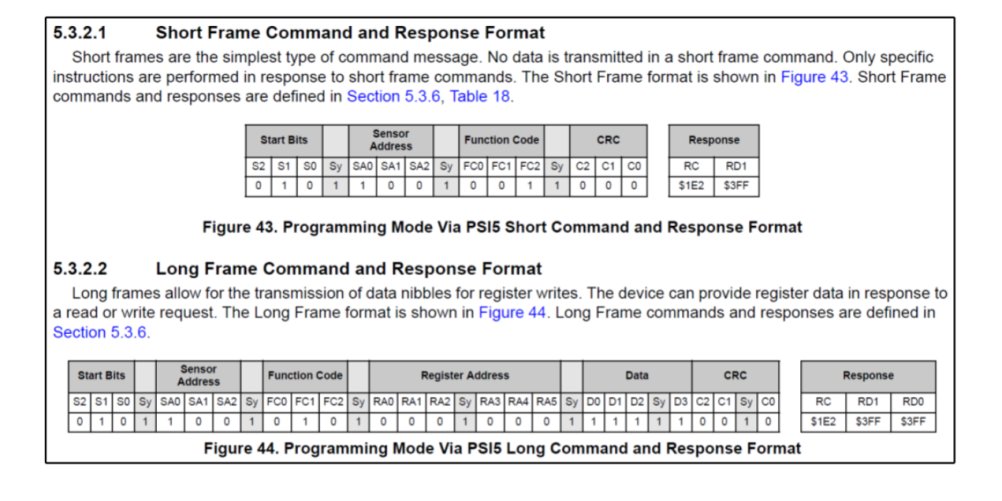

Hongke PSI5 devices support two command formats to address different diagnostic needs.

Short frame: No data payload, executes a specific command only. Suitable for simple diagnostic operations. Format includes start bit, sensor address, function code, and CRC.

Long frame: Supports register read/write data transmission for complex diagnostic configuration. Extends the short frame with register address and data fields.

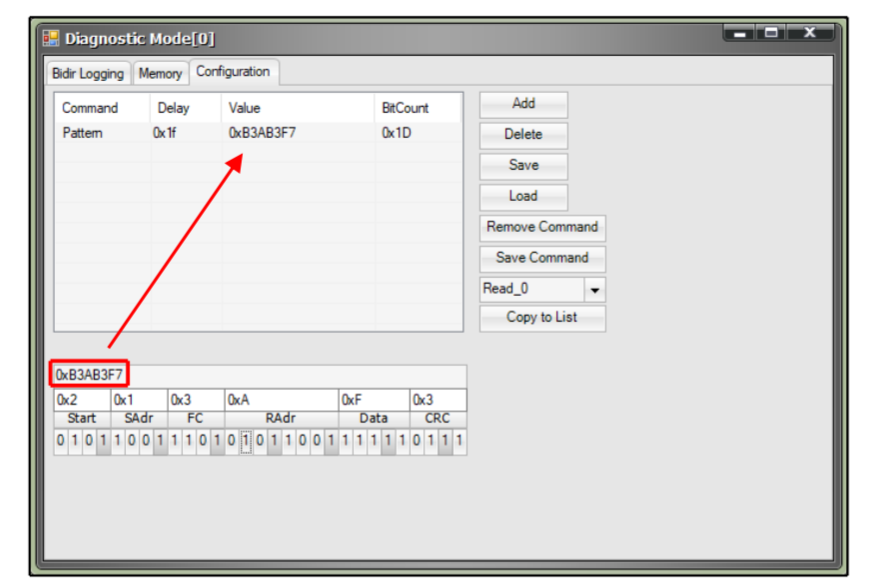

Custom diagnostic commands

In diagnostic mode, long-frame commands can be configured. Example configuration based on Hongke sensor specification: SAdr=0x1, FC=0x3, RAdr=0xA, Data=0xF, CRC=0xB3AB3F7. Add and save the command accordingly.

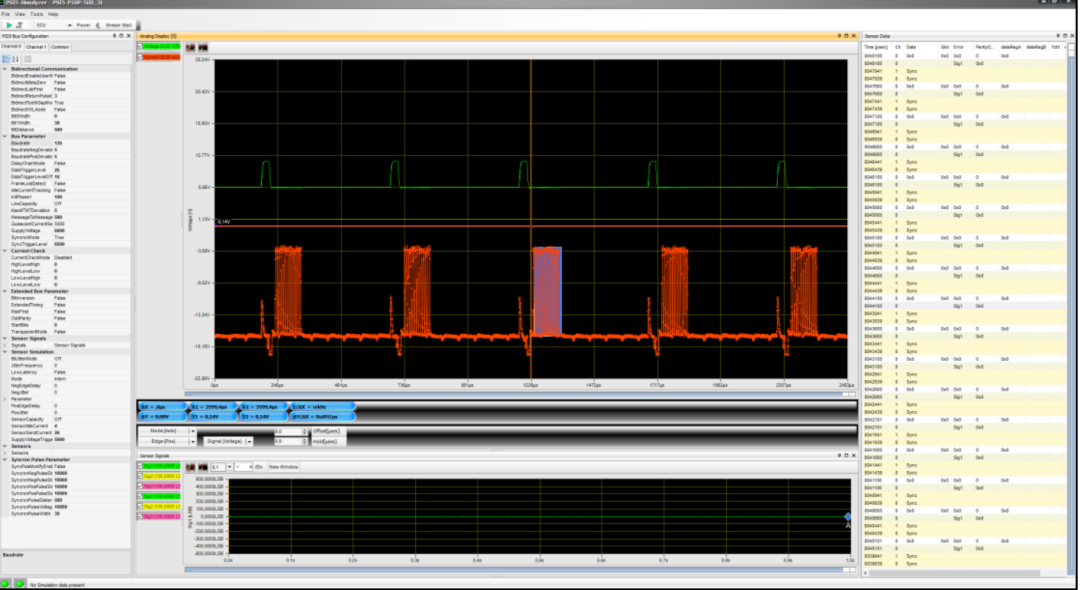

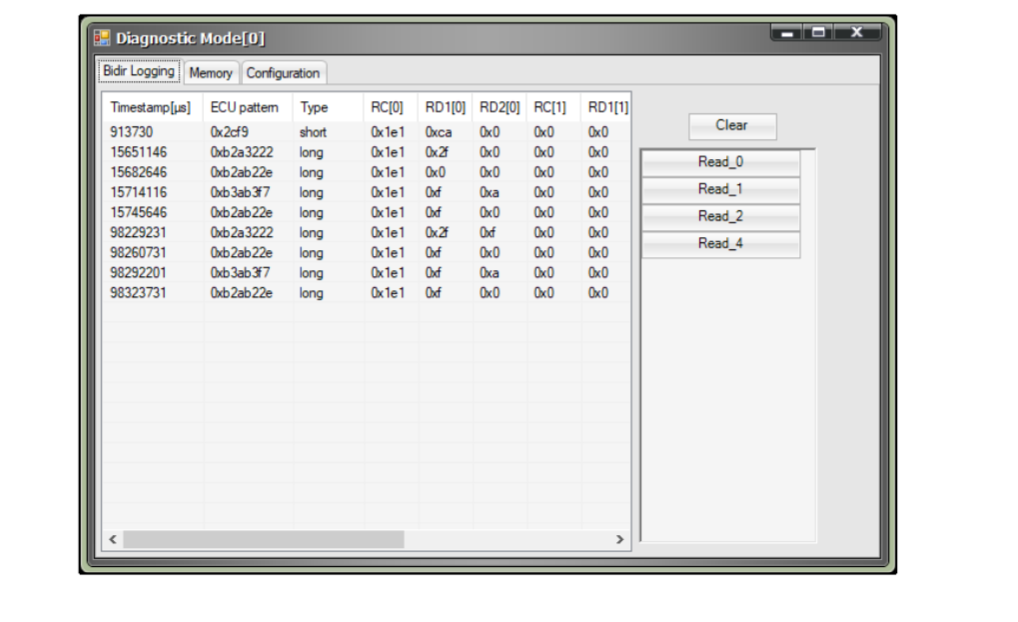

Log verification and execution

Use the device's bidirectional logging function to view timestamps, frame types, and response data for all configured commands. Select a command to execute the diagnostic operation and verify whether the PSI5-P10P-500-3L sensor has entered diagnostic mode successfully.

Conclusion

Hongke PSI5 sensors combine strong interference immunity, precise synchronization, safety compliance, and support for multiple slave devices to enable reliable sensor-to-controller communication in automotive and industrial applications. Programming relies on following the sensor manual and precise parameter configuration. Software-level logic can achieve coordinated operation with ECUs without hardware modification, providing foundational technical support for safe operation in harsh conditions.

ALLPCB

ALLPCB