Designing a printed circuit board (PCB) with proper impedance control is crucial for ensuring signal integrity, especially in high-speed electronic systems. If you're wondering how to optimize your PCB layout for impedance control, the answer lies in careful planning, precise routing techniques, and adherence to best design practices. In this comprehensive guide, we'll dive deep into the essentials of PCB layout impedance control, explore the best PCB design practices, and share effective PCB routing techniques for impedance to help you achieve optimal performance.

Why Impedance Control Matters in PCB Design

Impedance control in PCB design is the process of maintaining a consistent electrical impedance along signal traces to prevent signal distortion, reflections, and data loss. In high-speed circuits, where signals travel at frequencies above 100 MHz, mismatches in impedance can lead to significant issues like crosstalk and electromagnetic interference (EMI). For instance, a typical USB 2.0 signal requires a differential impedance of 90 ohms, and even a 10% deviation can cause signal degradation.

Without proper impedance control, your circuit may suffer from poor performance or even complete failure. This is why optimizing your PCB layout for impedance control is not just a best practice—it's a necessity for modern electronics. Whether you're designing for telecommunications, automotive systems, or consumer gadgets, understanding and applying these principles will ensure reliable operation.

Understanding the Basics of Impedance in PCB Layout

Before diving into best practices, let's break down what impedance means in the context of PCB design. Impedance is the opposition to the flow of alternating current (AC) in a circuit, measured in ohms. In PCBs, it depends on factors like trace width, trace thickness, dielectric material, and the distance between the trace and the ground plane.

For high-speed signals, two types of impedance are critical:

- Characteristic Impedance: This is the inherent impedance of a transmission line, typically ranging from 50 to 100 ohms in most designs.

- Differential Impedance: This applies to differential pairs, like those used in USB or HDMI, where two traces carry signals of equal magnitude but opposite polarity. Common values are 90 or 100 ohms.

Matching the impedance of your PCB traces to the source and load impedance is key to minimizing reflections. A mismatch, even as small as 5 ohms, can cause up to 10% signal reflection, leading to errors in data transmission.

Best Practices for PCB Layout Impedance Control

Achieving impedance control starts with a well-thought-out PCB layout. Below are some proven best practices to guide you through the process.

1. Choose the Right Materials for Your PCB

The dielectric material of your PCB plays a significant role in impedance control. The dielectric constant (Dk) of the material affects how signals propagate through the board. For high-speed designs, materials with a low Dk, such as FR-4 with a Dk of around 4.2 to 4.5, are commonly used. However, for ultra-high-speed applications (above 10 GHz), consider advanced materials like Rogers with a Dk as low as 3.0 for better signal integrity.

Work with your manufacturer to select a material that matches your impedance requirements. Also, ensure consistent material thickness, as variations can alter impedance values by up to 5%.

2. Calculate and Define Trace Geometry Precisely

Trace width and spacing directly impact impedance. Use an impedance calculator or simulation software to determine the exact dimensions for your traces. For a single-ended 50-ohm trace on a standard 1.6mm FR-4 board, a trace width of approximately 0.3mm with a 0.2mm dielectric height is often ideal. For differential pairs targeting 90 ohms, maintain equal trace widths (e.g., 0.2mm) and a spacing of about 0.3mm.

Consistency is key. Even a 0.05mm deviation in trace width can change impedance by 2-3 ohms, which is enough to disrupt signal integrity in high-speed designs.

3. Maintain a Continuous Ground Plane

A solid ground plane beneath signal traces is essential for controlling impedance and reducing EMI. It acts as a return path for high-frequency signals, stabilizing the impedance. Avoid splitting the ground plane under critical traces, as this can increase impedance by up to 20% and introduce noise.

For multi-layer boards, place high-speed signals on layers adjacent to a ground plane. A typical 4-layer stack-up might have signal layers on the top and bottom, with ground and power planes in the middle for optimal shielding.

4. Control Trace Length and Routing Paths

Long traces can introduce unwanted inductance and capacitance, altering impedance. Keep high-speed traces as short as possible, ideally under 1/10th of the signal wavelength. For a 1 GHz signal, this means traces shorter than 30mm.

Also, avoid sharp bends in traces. Use 45-degree angles or curved paths instead of 90-degree turns to prevent impedance discontinuities. Each sharp corner can cause a small reflection, adding up to significant signal loss over multiple turns.

PCB Routing Techniques for Impedance Control

Routing is where impedance control truly comes to life. The way you route your traces can make or break signal integrity. Here are some essential PCB routing techniques for impedance.

1. Route Differential Pairs Correctly

For differential signals, ensure both traces in the pair are of equal length and maintain consistent spacing. A length mismatch of just 0.5mm can introduce a timing skew of 3-5 picoseconds, enough to cause errors in high-speed data transmission.

Route differential pairs close together to maintain coupling and reduce noise. Use simulation tools to verify that the differential impedance remains within 5% of the target value (e.g., 90 ohms for USB).

2. Avoid Crossing Split Planes

Routing traces over splits in ground or power planes disrupts the return path, causing impedance spikes. If a trace must cross a split, add a stitching capacitor near the crossing point to provide a low-impedance return path. This can reduce impedance variation by up to 15%.

3. Use Vias Sparingly

Vias introduce inductance and capacitance, altering impedance. For high-speed signals, minimize via usage. If vias are unavoidable, use back-drilling to remove unused via stubs, which can reduce signal reflection by up to 10%. Also, ensure vias are placed symmetrically for differential pairs to avoid skew.

4. Separate High-Speed and Low-Speed Signals

Keep high-speed traces away from low-speed or noisy signals to prevent crosstalk. Maintain a spacing of at least 3 times the trace width between critical signals. For example, if your trace width is 0.2mm, keep a 0.6mm gap to minimize interference.

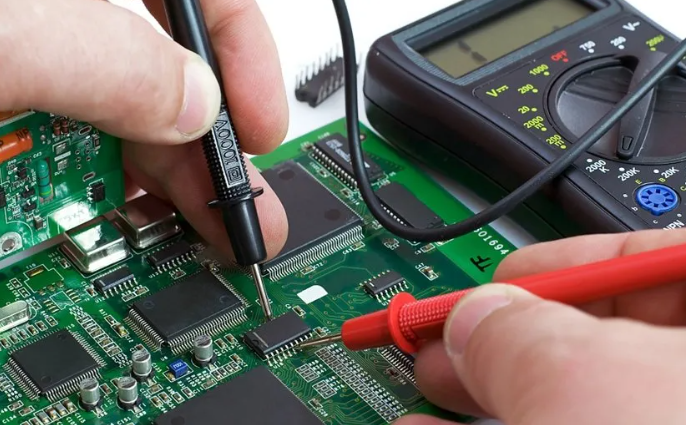

Tools and Simulations for Impedance Control

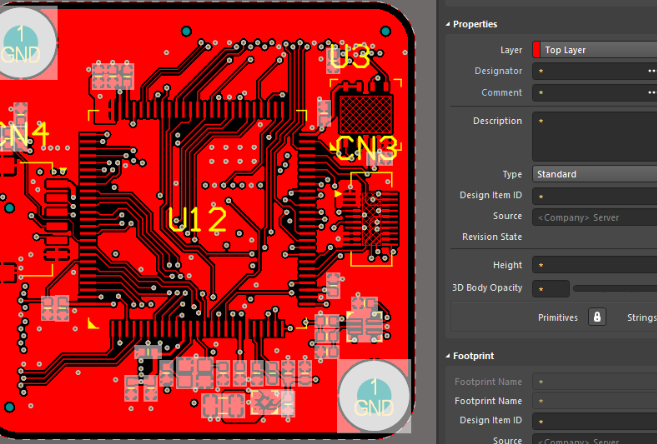

Modern PCB design tools offer built-in features to help with impedance control. Use field solvers and impedance calculators to predict trace behavior before fabrication. Simulate your layout to identify potential mismatches and adjust trace geometry or stack-up as needed.

Additionally, work closely with your PCB manufacturer during the design phase. Provide them with detailed impedance requirements, such as a target of 50 ohms ±10% for single-ended traces, to ensure the fabricated board meets your specifications.

Common Challenges in Impedance Control and How to Overcome Them

Even with the best practices, challenges can arise during PCB design. Here are a few common issues and solutions:

- Material Variations: Slight differences in dielectric properties can affect impedance. Specify tight tolerances (e.g., ±0.1 for Dk) when ordering materials.

- Manufacturing Tolerances: Etching processes can vary trace widths by ±10%. Request controlled impedance traces from your manufacturer and include test coupons on the board for verification.

- Complex Stack-Ups: In multi-layer boards, improper layer arrangement can disrupt impedance. Use a symmetrical stack-up and simulate the design to confirm performance.

Final Thoughts on Optimizing PCB Layout for Impedance Control

Optimizing your PCB layout for impedance control is a critical step in achieving reliable, high-performance electronics. By following the best PCB design practices outlined above—such as selecting the right materials, calculating trace geometry, maintaining ground planes, and using proper routing techniques—you can minimize signal integrity issues and ensure your design meets its performance goals.

Remember that impedance control is not a one-size-fits-all process. Each design has unique requirements based on signal speed, board complexity, and application. Take the time to simulate, test, and collaborate with your manufacturer to fine-tune your layout. With these strategies for PCB layout impedance control and PCB routing techniques for impedance, you're well on your way to creating robust and efficient designs.