Introduction

Sensor performance and suitability play a critical role in electronic product behavior. This article examines the MSX-360 mini joystick position sensor from PIHER, focusing on its compact design and technical characteristics.

Product overview

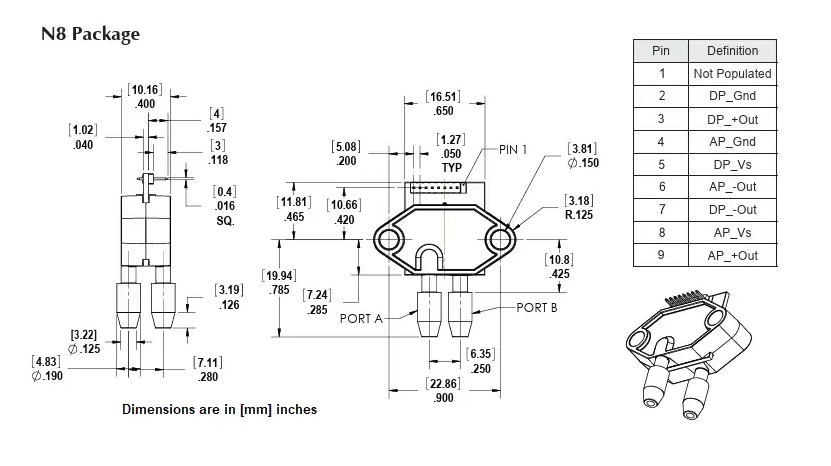

The MSX-360 integrates professional-level features into a very small footprint, measuring 14.4 mm x 16 mm. Despite its light weight, it delivers full-range 360° precise control with no dead zone. Up to 12-bit resolution ensures smooth response and long operational life. The sensor also provides resistance to electromagnetic interference and electrostatic discharge for reliable operation.

It is presented as a lower-cost alternative to contact-based solutions such as printed carbon tracks or potentiometers, which are prone to wear over their lifetime. The MSX-360 uses a low-profile design and a long service life to address those wear-related issues.

Key features and applications

Key features

- Non-contact operation: No gears or mechanical interfaces, simplifying assembly and calibration while minimizing wear over life.

- Small footprint: Minimal weight and package size enable use in space-constrained applications.

- Integrated shaft design: The magnet is securely fixed to the shaft, which is the only moving part in the sensor.

- 360° absolute position feedback: Unlimited mechanical rotation with no dead zone. Position is retained when power is removed. The electrical angle can be programmed between 90° and 360°.

Applications

- HMI interfaces: Provides precise user control feedback.

- Medical joysticks: Meets medical equipment requirements for accuracy and reliability.

- Industrial joysticks: Suitable for complex industrial control operations.

- Radio control: Enables precise remote control.

- Throttle control: Ensures accurate engine or motor control.

- Control levers: Provides stable positional feedback for mechanical control.

- Valve position control: Precise control of valve opening and closing.

Specifications

Mechanical specifications

| Item | Specification |

|---|---|

| Rotational life | Up to 7,000,000 cycles (higher life options available on request) |

| Mechanical range | 360° (infinite rotation) |

| Magnetic shielding | Built-in |

| Shaft diameter | 5.9 mm |

| Maximum mounting torque | 1 N·m |

Electrical specifications

| Item | Specification |

|---|---|

| Linearity | ±1.5% absolute |

| Electrical angle options | 90°, 180°, 270°, 360° |

| Output protocol | Analog (proportional) |

| Output | Simple |

| Resolution | Up to 12-bit |

| Supply voltage | 5 V ±10% |

| Supply current | Typical 12.6 mA |

| Voltage protection | +20 V / -10 V |

| Self-diagnostics | Yes |

Environmental specifications

| Characteristic | Standard | Rating |

|---|---|---|

| Operating and storage temperature | n/a | -40°C to +125°C |

| Shock | EN 60068-2-27 | 500 m/s2, 11 ms, 3 shocks per axis (room temperature) |

| Vibration | EN 60068-2-6 | 200 m/s2, 5–500 Hz, 10 minutes, 3 axes, 2 hours (room temperature) |

| Sealing | IEC 60529 | IP67 |

| Electromagnetic susceptibility (EMS) | ISO 11452-2 | 100 V/m, 1 MHz–1 GHz |

| Electrostatic discharge (ESD) | IEC 61000-4-2 | Contact discharge - housing to each terminal: +15 kV; contact discharge - between terminals: +15 kV |

Ordering information

Model format example: MSX360-1A-C004-ERA360-05K. The code includes output type, series, supply voltage, temperature range, and electrical rotation angle. ERA090, ERA180, ERA270, and ERA360 indicate different electrical rotation angles. For other output types, refer to the MSC360 micro position sensor family.

Output behavior and considerations

The sensor output voltage depends on shaft position; different mechanical rotation angles correspond to different output voltages. Ferromagnetic materials near the sensor can affect linearity, so avoid placing such materials nearby. If external magnetic interference may be present, provide details about the magnetic flux sources (for example, magnets, cables, motors) to PIHER for magnetic simulation analysis and updates.

ALLPCB

ALLPCB