In the fast-paced world of industrial automation, every second counts. Indicator lights play a vital role in keeping operations running smoothly by providing instant visual feedback on machine status, warnings, and safety conditions. Whether you're managing a factory floor or designing automated systems, understanding how industrial indicator lights enhance safety and efficiency is key to optimizing performance. In this blog, we'll dive deep into the importance of automation status indicators, machine warning lights, safety indicator lights, and PLC indicator control, offering practical insights for engineers and industry professionals.

What Are Industrial Indicator Lights and Why Do They Matter?

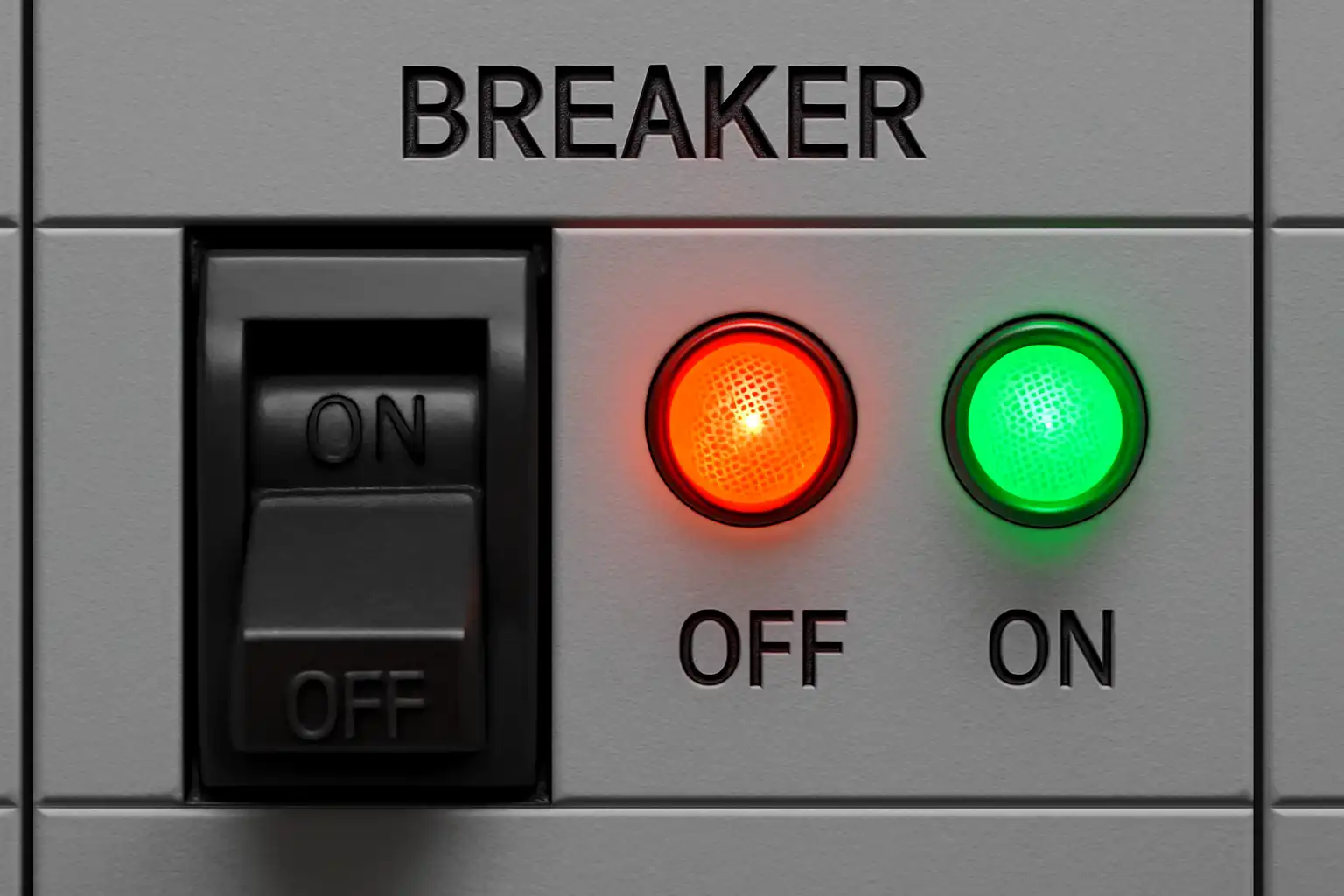

Industrial indicator lights are visual signaling devices used in manufacturing and automation environments to communicate the status of machines, processes, or systems. Often referred to as automation status indicators or machine warning lights, these lights help operators and technicians quickly identify whether a machine is running, stopped, or experiencing an issue. They are essential for maintaining safety, reducing downtime, and improving overall efficiency on the factory floor.

These lights come in various forms, such as stack lights (also called tower lights), panel indicators, and LED signal lights. They use color-coded signals—red for warnings, green for normal operation, yellow for alerts, and blue for specific conditions—to provide clear, at-a-glance information. With the integration of Programmable Logic Controllers (PLCs), indicator lights can be customized for precise control, ensuring real-time updates on critical operations.

The Role of Indicator Lights in Industrial Automation

Indicator lights are more than just blinking signals; they are a cornerstone of modern industrial automation. Here's how they contribute to safety and efficiency:

1. Real-Time Status Updates with Automation Status Indicators

Automation status indicators provide immediate feedback on the operational state of equipment. For instance, a green light might signal that a conveyor belt is running at full capacity, while a flashing yellow light could indicate a slowdown due to a minor issue. This real-time feedback allows operators to respond quickly, preventing small issues from escalating into costly downtime.

In a typical setup, a stack light with multiple segments can display various conditions simultaneously. According to industry data, using visual indicators can reduce response times to machine issues by up to 30%, directly impacting productivity.

2. Enhancing Safety with Machine Warning Lights and Safety Indicator Lights

Safety is paramount in industrial settings, and machine warning lights are critical for alerting workers to potential hazards. A red light, for example, often signals an emergency stop or a critical fault, prompting immediate action. Safety indicator lights are also used to mark restricted areas or signal when protective equipment is required.

Consider a robotic arm in an assembly line: if a safety sensor detects an obstruction, a red warning light activates, and the system halts. Such mechanisms have been shown to reduce workplace accidents by as much as 25% in environments where visual cues are consistently used, based on safety reports from industrial studies.

3. Streamlining Operations with PLC Indicator Control

Programmable Logic Controllers (PLCs) are the brains behind many automated systems, and integrating indicator lights with PLCs allows for precise control over signaling. PLC indicator control enables lights to reflect specific conditions programmed into the system, such as temperature thresholds or pressure levels. For example, if a hydraulic press exceeds a pressure limit of 5000 psi, the PLC can trigger a yellow alert light to notify operators before a failure occurs.

This level of customization ensures that indicator lights are not just passive signals but active components of a smart automation system. Engineers can program delays, flash patterns, or even synchronize lights with audible alarms for maximum impact.

Types of Industrial Indicator Lights and Their Applications

Understanding the different types of industrial indicator lights helps in selecting the right solution for specific needs. Below are the most common types and their applications in automation:

- Stack Lights: These multi-segment lights are ideal for displaying multiple statuses at once. Often mounted on top of machines, they are visible from a distance, making them perfect for large factory floors. A typical stack light might use three colors: green for "running," yellow for "maintenance needed," and red for "stopped."

- Panel Indicator Lights: Mounted on control panels, these smaller lights are used to indicate the status of individual components, such as motors or valves. They are often LED-based for energy efficiency and long life, with lifespans exceeding 50,000 hours in many cases.

- Beacon Lights: These high-intensity lights are used for critical warnings, often accompanied by flashing or rotating patterns to draw attention. They are common in environments where noise levels might drown out audible alarms.

Benefits of Using Indicator Lights in Industrial Automation

Implementing industrial indicator lights offers several advantages for safety and efficiency. Let's explore these benefits in detail:

1. Improved Communication Across Teams

In a busy factory, verbal communication can be challenging due to noise or distance. Indicator lights provide a universal language that everyone—from operators to supervisors—can understand instantly. For example, a flashing red light universally means "stop" or "danger," eliminating confusion and ensuring a coordinated response.

2. Reduced Downtime and Maintenance Costs

By alerting operators to issues before they become major problems, automation status indicators help minimize unplanned downtime. A study in industrial automation found that facilities using visual signaling systems reported a 20% decrease in maintenance-related stoppages. Early warnings allow for scheduled repairs rather than emergency fixes, saving both time and money.

3. Enhanced Worker Safety

Safety indicator lights and machine warning lights act as the first line of defense against accidents. They warn workers of hazardous conditions, such as overheating equipment or unauthorized access to restricted zones. In high-risk industries like chemical processing, where a single error can lead to catastrophic results, these lights are indispensable.

How to Choose the Right Industrial Indicator Lights

Selecting the appropriate indicator lights for your automation system involves several considerations. Here are key factors to keep in mind:

- Environment: Will the lights be exposed to dust, moisture, or extreme temperatures? Choose lights with appropriate IP ratings (e.g., IP65 for dust and water resistance) to ensure durability. For outdoor applications, UV-resistant materials are a must.

- Visibility: Consider the size of the area and the distance from which the lights need to be seen. Stack lights are ideal for large spaces, while panel indicators work well for close-range monitoring.

- Power Source and Efficiency: LED-based indicator lights are popular due to their low power consumption (often less than 5 watts per light) and long lifespan, reducing replacement costs.

- Integration with PLCs: Ensure the lights can be easily integrated with your existing PLC systems for customized control. Check for compatibility with voltage levels, typically 24V DC in industrial settings, to avoid signal mismatches.

Best Practices for Implementing Indicator Lights in Automation Systems

To maximize the effectiveness of industrial indicator lights, follow these best practices:

- Standardize Color Coding: Stick to widely accepted color standards to avoid confusion. For instance, use green for normal operation, yellow for caution, and red for emergencies. Consistency across all machines ensures quick recognition by all staff.

- Regular Maintenance: Inspect lights for dust buildup or damage that could obscure visibility. Replace burnt-out bulbs or malfunctioning LEDs promptly to maintain reliability.

- Combine with Audible Alarms: In noisy environments, pair indicator lights with sirens or buzzers to ensure alerts are not missed. For critical warnings, a combination of a red light and a 90-decibel alarm can be highly effective.

- Train Staff: Educate all personnel on the meaning of each light and the appropriate response. Regular drills can reinforce these protocols, especially for safety indicator lights.

Future Trends in Industrial Indicator Lights

As technology evolves, so do the capabilities of industrial indicator lights. Here are some emerging trends to watch:

- Smart Indicator Lights: With the rise of Industry 4.0, indicator lights are becoming "smart" with IoT integration. These lights can send alerts to mobile devices or central dashboards, providing remote monitoring of machine status.

- Energy Efficiency: Advances in LED technology are making indicator lights even more energy-efficient, with some models consuming less than 2 watts while maintaining high brightness levels.

- Customizable Flash Patterns: Modern PLC indicator control systems allow for programmable flash patterns, enabling lights to convey more detailed information through varying blink rates or sequences.

Conclusion: Boosting Safety and Efficiency with Indicator Lights

Industrial indicator lights are indispensable tools in the world of automation, serving as the eyes and ears of complex systems. From providing real-time updates through automation status indicators to ensuring worker safety with machine warning lights, these devices enhance both efficiency and security on the factory floor. By leveraging PLC indicator control, businesses can customize signaling to meet specific needs, while advancements in technology promise even smarter solutions in the future.

For engineers and industry professionals, investing in high-quality industrial indicator lights is a step toward minimizing downtime, reducing costs, and creating a safer workplace. By understanding the types, benefits, and best practices outlined in this blog, you can make informed decisions to optimize your automation systems. Remember, a small light can make a big difference in the fast-moving world of industrial operations.

ALLPCB

ALLPCB