Choosing the right adhesives for electronic components is crucial for ensuring the reliability, performance, and longevity of your devices. Whether you're working on PCB semiconductor manufacturing, applying conformal coatings, or selecting electrical conductivity adhesives, the adhesive must match the specific needs of your project. Factors like thermal resistance, electrical properties, and environmental conditions play a big role in this decision. In this comprehensive guide, we'll walk you through the key considerations and types of adhesives, including those for die attach and other applications, to help you make an informed choice.

Why Adhesives Matter in Electronic Components

Adhesives are more than just a way to stick things together in electronics. They protect sensitive components, ensure electrical conductivity where needed, and maintain structural integrity under harsh conditions. A poor adhesive choice can lead to failures like delamination, short circuits, or thermal breakdown. For instance, in PCB semiconductor manufacturing, adhesives must withstand temperatures often exceeding 150°C during soldering processes. Selecting the right adhesive can mean the difference between a product lasting years or failing within months.

Key Factors to Consider When Choosing Adhesives for Electronic Components

Before diving into specific types of adhesives, let’s break down the critical factors that influence your choice. These considerations ensure the adhesive performs well in your specific application.

1. Thermal Resistance and Stability

Electronic components often operate in environments with fluctuating or high temperatures. Adhesives must resist thermal degradation to prevent cracking or loss of bond strength. For example, in die attach applications, adhesives need to handle temperatures up to 200°C during operation. Look for products with a high glass transition temperature (Tg), often above 100°C, to ensure stability under heat stress.

2. Electrical Properties

Depending on the application, adhesives may need to be electrically conductive or insulating. Electrical conductivity adhesives are essential for connecting components where current flow is required, offering volume resistivity as low as 0.001 ohm-cm in some formulations. On the other hand, insulating adhesives used in conformal coatings must prevent short circuits with high dielectric strength, often exceeding 1000 volts per mil.

3. Chemical and Environmental Resistance

Electronics are often exposed to moisture, dust, and chemicals. Adhesives, especially conformal coatings, must protect against corrosion and environmental damage. For instance, a coating with a moisture resistance rating of IP65 or higher can safeguard components in humid conditions. Consider the operating environment of your device when selecting an adhesive with appropriate resistance properties.

4. Mechanical Strength and Flexibility

Adhesives must provide a strong bond while allowing for some flexibility to absorb vibrations or thermal expansion. In PCB semiconductor manufacturing, a tensile strength of at least 5000 psi is often necessary to ensure components stay in place during assembly and use. Flexibility is equally important to prevent cracking under stress.

5. Cure Time and Application Method

The curing process affects production speed and efficiency. Some adhesives cure at room temperature in 24 hours, while others require heat curing at 120°C for just 30 minutes. Choose an adhesive that aligns with your manufacturing capabilities and timelines. Also, consider whether the adhesive is applied via dispensing, spraying, or brushing, as this impacts ease of use.

Types of Adhesives for Electronic Components

Now that we’ve covered the key factors, let’s explore the main types of adhesives used in electronics. Each type serves a unique purpose, from bonding to protection.

1. Electronic Components Adhesives for General Bonding

These adhesives are used to secure components like capacitors, resistors, and connectors to a PCB. Epoxy-based adhesives are a popular choice due to their high strength and thermal resistance, often providing bond strengths of over 3000 psi. They’re ideal for applications where durability is critical. Silicone adhesives, on the other hand, offer flexibility and are better suited for components subject to vibration.

2. Conformal Coatings for Protection

Conformal coatings are thin protective layers applied over assembled PCBs to shield against moisture, dust, and chemical exposure. Common types include acrylic, silicone, and urethane coatings. Acrylic coatings, for instance, offer good moisture resistance with a dielectric strength of around 1100 volts per mil and are easy to apply. Silicone coatings excel in high-temperature environments, maintaining integrity up to 200°C. When choosing a conformal coating, consider the environmental challenges your PCB will face and ensure compatibility with rework or repair processes.

3. Die Attach Adhesives for Semiconductor Bonding

Die attach adhesives bond semiconductor chips to substrates or packages in PCB semiconductor manufacturing. These adhesives must provide excellent thermal conductivity, often around 1.5 W/m·K, to dissipate heat from the chip. Silver-filled epoxies are commonly used for their balance of conductivity and strength, ensuring reliable performance during temperature cycles from -55°C to 150°C. The adhesive must also minimize voids during application to prevent hotspots.

4. Electrical Conductivity Adhesives for Connections

Electrical conductivity adhesives replace traditional soldering in some applications, especially where heat-sensitive components are involved. These adhesives contain conductive fillers like silver or carbon, achieving low electrical resistance (e.g., 0.0001 ohm-cm). They’re widely used in flexible circuits and wearable electronics, providing reliable connections without the risk of thermal damage. Ensure the adhesive’s conductivity matches your circuit’s current requirements for optimal performance.

5. Potting and Encapsulation Compounds

Potting compounds encase entire assemblies to protect against shock, vibration, and environmental factors. These are often epoxy or silicone-based, with viscosity ranging from 500 to 5000 cP to ensure proper flow during application. Encapsulation is critical for rugged applications like automotive electronics, where components face extreme conditions. Look for compounds with low shrinkage (less than 1%) to avoid stress on components during curing.

Application-Specific Considerations in PCB Semiconductor Manufacturing

In PCB semiconductor manufacturing, adhesives play a specialized role in ensuring precision and reliability. The process often involves high-speed assembly, extreme temperatures, and miniaturized components. Here’s what to focus on for specific applications.

Die Bonding in Semiconductor Production

Die bonding requires adhesives with high thermal conductivity and minimal outgassing to avoid contamination. Outgassing levels should be below 1% to prevent void formation, which can lead to thermal inefficiencies. Automated dispensing systems often apply these adhesives with precision, ensuring consistent bond lines as thin as 25 microns.

Surface Mount Technology (SMT) Assembly

In SMT, adhesives temporarily hold components in place before soldering. These adhesives must cure quickly, often in under 10 seconds under UV light, to maintain production speed. They should also have a shear strength of at least 1000 psi to withstand handling during assembly.

Flexible and Wearable Electronics

For flexible circuits and wearables, adhesives must offer low modulus (below 100 MPa) to maintain flexibility without cracking. Electrical conductivity adhesives are often used here to create lightweight, reliable connections without the bulk of traditional soldering.

How to Match Adhesives to Your Project Needs

Selecting the right adhesive involves aligning its properties with your project’s requirements. Start by defining the operating conditions, such as temperature range (-40°C to 125°C is common for automotive electronics) and exposure to chemicals or humidity. Next, identify the electrical needs—does the adhesive need to conduct current or insulate? Finally, consider the manufacturing process. Can your setup handle heat curing, or do you need a room-temperature cure?

A practical approach is to create a checklist of must-have properties based on the factors discussed earlier. For example, if you’re working on a high-power device, prioritize thermal conductivity and high Tg. For outdoor applications, focus on environmental resistance with a high IP rating. Testing small batches with different adhesives can also help determine the best fit before full-scale production.

Common Challenges and How to Avoid Them

Even with careful selection, issues can arise when using adhesives in electronics. Here are some common problems and solutions.

1. Poor Adhesion

If an adhesive fails to bond properly, it’s often due to surface contamination. Clean surfaces thoroughly with isopropyl alcohol and ensure they’re free of dust or oils before application. Some adhesives also require primers to enhance adhesion on challenging substrates like polyimide.

2. Thermal Mismatch

Components and substrates expand at different rates when heated, stressing the adhesive. Choose an adhesive with a coefficient of thermal expansion (CTE) close to that of the materials being bonded, ideally within 10 ppm/°C, to minimize stress.

3. Incomplete Curing

Improper curing can weaken bonds. Follow the manufacturer’s guidelines for temperature and time— for example, curing at 80°C for 2 hours instead of the recommended 120°C for 30 minutes can lead to incomplete polymerization. Use curing ovens or UV lamps as needed for consistent results.

Best Practices for Applying Adhesives in Electronics

Application technique is just as important as adhesive selection. Follow these best practices to ensure optimal performance.

- Surface Preparation: Always clean and roughen surfaces if needed to improve adhesion. A surface roughness of Ra 0.8 μm can enhance bond strength.

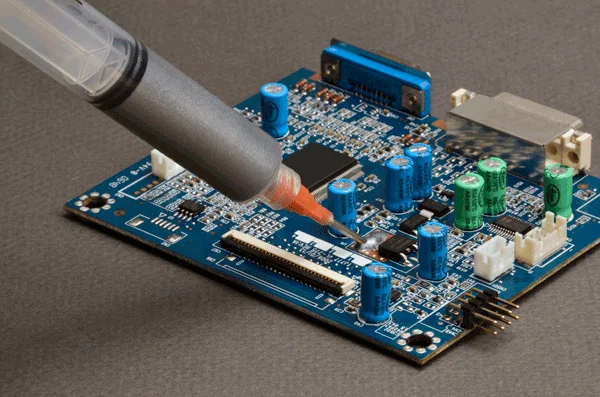

- Precision Dispensing: Use automated dispensers for consistent adhesive volume, especially in die attach applications where bond lines must be uniform.

- Controlled Environment: Apply adhesives in a dust-free, temperature-controlled setting to avoid contamination or curing issues. A relative humidity of 40-60% is often ideal.

- Testing: After application, test assemblies for bond strength and electrical performance. For conductivity adhesives, measure resistance to ensure it’s below the required threshold, such as 0.01 ohm-cm.

Future Trends in Electronic Components Adhesives

The electronics industry is evolving rapidly, and so are adhesive technologies. With the rise of miniaturization, adhesives are being developed for even smaller bond lines, sometimes as thin as 10 microns. Additionally, eco-friendly formulations with low volatile organic compounds (VOCs) are gaining traction to meet environmental regulations. In electrical conductivity adhesives, new materials like graphene are being explored to achieve resistivities below 0.0005 ohm-cm, pushing the boundaries of performance in high-speed circuits.

Conclusion: Making the Right Choice for Your Electronics Project

Choosing the right adhesives for electronic components is a balance of technical requirements and practical considerations. Whether you’re focused on conformal coatings for protection, die attach for semiconductor bonding, or electrical conductivity adhesives for connections, understanding the properties and applications of each type is key. By considering factors like thermal resistance, electrical needs, and environmental conditions, you can ensure your adhesive enhances the performance and durability of your electronics. With the right approach, your PCB semiconductor manufacturing process will yield reliable, high-quality results tailored to your specific needs.

Armed with this guide, you’re ready to navigate the complex world of electronic adhesives with confidence. Take the time to evaluate your project’s unique demands, test different options if possible, and apply best practices for flawless execution. Your electronic components deserve nothing less than the perfect bond.

ALLPCB

ALLPCB