In the fast-evolving world of electronics, high-performance multi-layer PCBs are at the heart of cutting-edge technology. Whether you're designing for 5G communications, automotive systems, or aerospace applications, the materials used in these printed circuit boards play a critical role in ensuring reliability, speed, and efficiency. So, what are the best materials for high-performance multi-layer PCBs? This blog dives deep into advanced options like low-loss multi-layer PCB materials, high-frequency laminates, PTFE, and ceramic-based solutions, helping you choose the right one for your project.

At ALLPCB, we understand the importance of selecting the right materials to meet the demands of modern electronics. In this comprehensive guide, we'll explore the characteristics, benefits, and applications of these advanced materials, providing you with the knowledge to make informed decisions for your next design.

Why Material Choice Matters in Multi-Layer PCBs

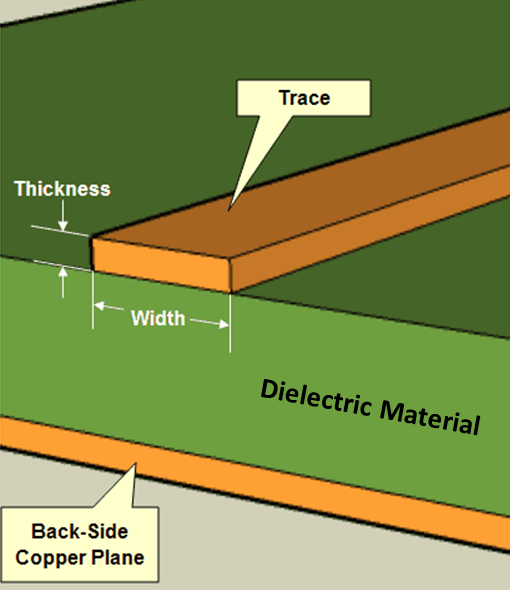

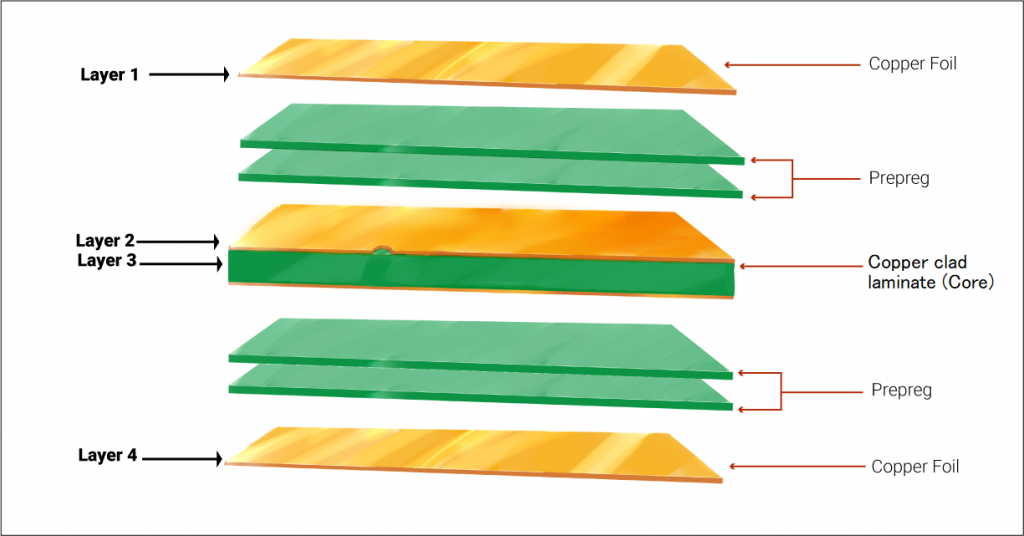

Multi-layer PCBs are complex structures with multiple layers of conductive and insulating materials stacked together. These boards are essential for compact, high-density designs in devices like smartphones, medical equipment, and high-speed communication systems. However, not all materials can handle the challenges of high-frequency signals, thermal stress, or signal integrity requirements.

The right material can reduce signal loss, manage heat effectively, and ensure consistent performance under demanding conditions. Poor material choices, on the other hand, can lead to issues like delamination, signal distortion, or even complete failure of the board. With that in mind, let's look at some of the most advanced materials for high-performance multi-layer PCBs.

Key Characteristics of High-Performance Multi-Layer PCB Materials

Before diving into specific materials, it's important to understand the properties that define high-performance in PCB design. When selecting materials for multi-layer boards, engineers often focus on the following:

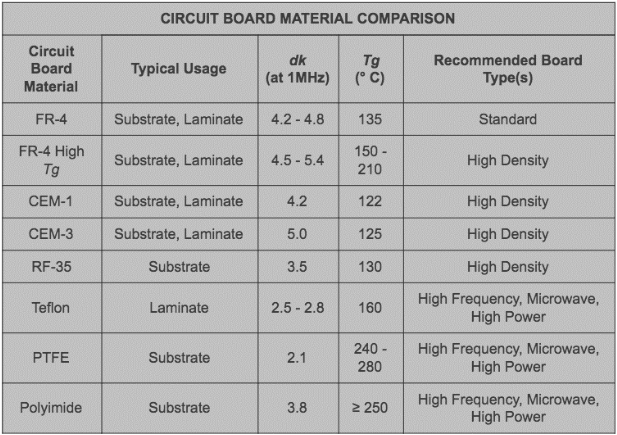

- Dielectric Constant (Dk): A lower Dk value reduces signal delay and is critical for high-frequency applications. Values typically range from 2.2 to 4.5 for advanced materials.

- Dissipation Factor (Df): This measures signal loss. Low-loss materials have Df values below 0.005, ensuring minimal energy loss at high frequencies.

- Thermal Conductivity: High thermal conductivity (above 0.5 W/mK) helps dissipate heat in power-intensive applications.

- Mechanical Strength: Materials must withstand the stress of manufacturing processes and environmental conditions without cracking or delaminating.

- Cost vs. Performance: Balancing performance needs with budget constraints is always a consideration in material selection.

With these properties in mind, let’s explore the specific materials that excel in high-performance multi-layer PCB designs.

Low-Loss Multi-Layer PCB Materials for Signal Integrity

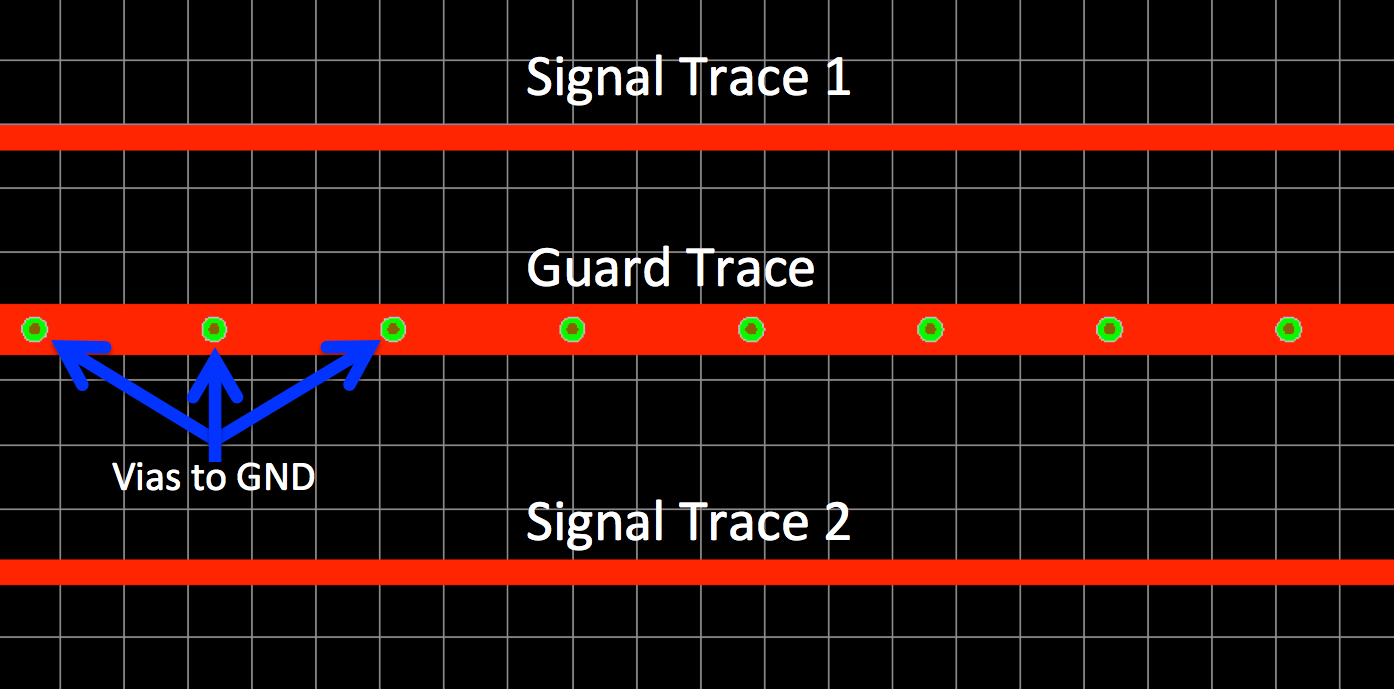

Signal integrity is a top priority in high-speed and high-frequency applications. Low-loss multi-layer PCB materials are designed to minimize signal degradation, making them ideal for telecommunications, data centers, and advanced computing systems.

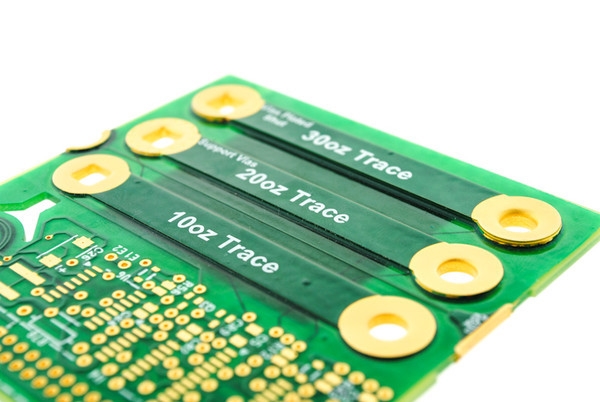

These materials typically feature a low dissipation factor (Df), often below 0.003, which ensures that signals maintain their strength over long distances on the board. They also have stable dielectric constants, preventing variations in signal speed that could disrupt performance. For instance, in 5G infrastructure, low-loss materials support data rates exceeding 28 Gbps while maintaining signal clarity.

Applications for low-loss multi-layer PCB materials include:

- High-speed digital circuits

- RF and microwave systems

- Server and networking equipment

By using low-loss materials, designers can achieve tighter impedance control, often within ±5% of target values, ensuring reliable performance in critical systems.

High-Frequency Laminates for Multi-Layer PCBs

High-frequency laminates for multi-layer PCBs are engineered to perform in environments where signals operate at frequencies above 1 GHz. These materials are essential for applications like radar systems, satellite communications, and wireless networks, where even small signal losses can lead to significant performance issues.

High-frequency laminates often have dielectric constants ranging from 2.2 to 3.5, allowing for faster signal propagation. Their low dissipation factors (typically below 0.002) minimize energy loss, which is critical at high frequencies. Additionally, these laminates offer excellent thermal stability, maintaining performance even under temperature fluctuations from -40°C to 85°C.

Common applications include:

- 5G and 6G communication systems

- Automotive radar and ADAS (Advanced Driver Assistance Systems)

- Aerospace and defense electronics

Using high-frequency laminates in multi-layer PCBs ensures that your designs can handle the demands of modern high-speed technologies without compromising reliability.

PTFE Multi-Layer PCBs for Superior Performance

Polytetrafluoroethylene (PTFE) is a standout material for high-performance multi-layer PCBs, especially in high-frequency and microwave applications. Known for its exceptional electrical properties, PTFE offers one of the lowest dielectric constants available, often around 2.1, and a dissipation factor as low as 0.0003.

PTFE multi-layer PCBs are highly resistant to moisture, chemicals, and temperature extremes, making them suitable for harsh environments. They can operate effectively in temperatures ranging from -55°C to 150°C, which is ideal for aerospace and industrial applications. Additionally, PTFE’s low signal loss properties make it perfect for RF circuits where maintaining signal strength is critical.

Key benefits of PTFE multi-layer PCBs include:

- Excellent performance at frequencies up to 10 GHz and beyond

- High resistance to environmental stress

- Stable electrical properties over a wide range of conditions

While PTFE materials can be more expensive than traditional options, their unmatched performance in demanding applications often justifies the cost.

Ceramic Multi-Layer PCBs for Thermal and Mechanical Strength

Ceramic multi-layer PCBs are another advanced option for high-performance designs, particularly where thermal management and mechanical durability are priorities. These materials, often made from alumina or aluminum nitride, offer thermal conductivity values as high as 170 W/mK, far exceeding traditional laminates.

Ceramic materials also provide a high dielectric constant, typically between 8 and 10, which can be beneficial for specific high-frequency designs. Their robust mechanical strength prevents cracking or deformation during manufacturing or operation, even under high stress. This makes ceramic multi-layer PCBs ideal for power electronics, LED lighting, and automotive systems where heat dissipation is critical.

Advantages of ceramic multi-layer PCBs include:

- Superior heat dissipation for high-power applications

- High mechanical stability for rugged environments

- Long-term reliability in extreme conditions

While ceramic materials may not be suitable for every application due to their higher cost and rigidity, they are an excellent choice for designs where durability and thermal performance are non-negotiable.

Comparing Advanced Materials for Multi-Layer PCBs

Choosing the right material for your multi-layer PCB depends on the specific requirements of your project. Below is a comparison of the materials discussed, highlighting their strengths and ideal use cases:

| Material | Dielectric Constant (Dk) | Dissipation Factor (Df) | Thermal Conductivity (W/mK) | Best Applications |

|---|---|---|---|---|

| Low-Loss Laminates | 3.0 - 4.0 | < 0.003 | 0.3 - 0.5 | High-speed digital, networking |

| High-Frequency Laminates | 2.2 - 3.5 | < 0.002 | 0.4 - 0.6 | RF, microwave, 5G systems |

| PTFE | ~2.1 | ~0.0003 | 0.2 - 0.3 | High-frequency, harsh environments |

| Ceramic | 8.0 - 10.0 | ~0.001 | Up to 170 | Power electronics, automotive |

This table can serve as a quick reference when deciding which material aligns with your design goals. Consider factors like frequency range, thermal demands, and environmental conditions to narrow down your options.

Applications Driving Demand for Advanced PCB Materials

The growing complexity of electronic devices has fueled the need for high-performance multi-layer PCB materials. Some of the key industries driving this demand include:

- Telecommunications: With the rollout of 5G and future 6G networks, low-loss and high-frequency laminates are essential for handling ultra-fast data rates and minimizing latency.

- Automotive: Advanced driver assistance systems (ADAS) and electric vehicles rely on ceramic and high-frequency materials for radar, sensors, and power management.

- Aerospace and Defense: PTFE and ceramic materials provide the reliability needed for mission-critical systems operating in extreme conditions.

- Consumer Electronics: Compact, high-density devices like smartphones and wearables benefit from multi-layer designs with low-loss materials for efficient signal routing.

As these industries continue to innovate, the demand for advanced PCB materials will only grow, pushing the boundaries of what’s possible in electronics design.

How to Choose the Right Material for Your Multi-Layer PCB

Selecting the best material for your high-performance multi-layer PCB involves balancing technical requirements with practical considerations. Start by defining the key parameters of your project, such as:

- Operating frequency and signal speed requirements

- Thermal and environmental conditions

- Mechanical stress and durability needs

- Budget constraints and production scalability

Once you have a clear understanding of these factors, match them to the material properties discussed in this guide. For example, if your design operates at 5 GHz and requires minimal signal loss, PTFE or high-frequency laminates would be the top choices. On the other hand, for high-power applications with significant heat generation, ceramic materials might be the better option.

Working with a trusted manufacturing partner can also simplify the decision-making process. At ALLPCB, we provide expert guidance and a wide range of material options to ensure your multi-layer PCB meets the highest performance standards.

Conclusion: Building the Future with Advanced PCB Materials

High-performance multi-layer PCBs are the backbone of modern electronics, and choosing the right materials is essential for success. Whether you opt for low-loss multi-layer PCB materials, high-frequency laminates, PTFE, or ceramic solutions, each offers unique benefits tailored to specific applications. By understanding the properties and advantages of these advanced materials, you can design boards that deliver exceptional reliability, speed, and efficiency.

At ALLPCB, we’re committed to supporting engineers and designers with top-quality materials and manufacturing services. As technology continues to advance, we’re here to help you stay ahead of the curve with innovative solutions for your multi-layer PCB needs. Explore our offerings and see how we can bring your designs to life with the best materials available.

ALLPCB

ALLPCB