Today six 5G + industrial internet innovation application cases are presented. The cases were collected through a survey organized by the Zhejiang Provincial Department of Economy and Information Technology and compiled by the Zhejiang 5G Industry Alliance under that department's guidance.

Case 1: Safety Applications of 5G Industrial Internet in Fine Chemicals

Reporting unit: China Telecom Hangzhou Branch

Main business: Systems integration, technology development and services related to telecommunications and information services; sales, design and installation of communication products; information consulting; advertising services.

Partners: Zhejiang Xin'an Chemical Group Co., Ltd.; Zhejiang ControlTech Zhixin Technology Co., Ltd.; Hikvision Digital Technology Co., Ltd.

01 Overview

Xin'an Group is a leading China-based company in silicon-based new materials with a complete industry chain including silicone rubber, silicone oil, silicone resin, and silane coupling agents. Its monomer production ranks second nationwide, with globally competitive technology and the most comprehensive downstream product range. As China pursues innovation-driven development, Xin'an has prioritized intelligent manufacturing to implement hazardous-chemical production risk monitoring and early-warning systems and data acquisition. As an industry leader, the company also aims to demonstrate best practices for the broader sector through intelligent manufacturing applications.

The project leverages 5G's high bandwidth, low latency, and broad connectivity and applies AI to plant-wide video monitoring resources to optimize chemical production scenarios. Based on the company's existing systems, the platform builds high-precision models of selected buildings and core equipment, collects and aggregates key production-device data, and overlays these data on real-time rendered 3D visualization for management and queries. A foundational video analysis platform aggregates existing cameras and adds mobile deployment cameras. Using the 5G network to feed video into the platform, the project implements AI-based 5G security monitoring and 5G-based explosion-proof terminal safety management with precise positioning.

The overall objective is to build a 5G-enabled collaborative manufacturing solution that integrates industrial networks, industrial software, and control systems, accelerating adoption of industrial collaborative manufacturing platforms and supporting the digital, networked, and intelligent transformation of manufacturing. Specific goals include: 1) use 5G low latency and high bandwidth to enable real-time HD video uplink within workshops; 2) route video streams via 5G base stations to video servers, with the platform pulling streams from servers to present them in the enterprise information center; 3) improve shop-floor management such as worker behavior analysis, PPE detection, and hazardous-material transport monitoring.

02 Key technologies

Edge computing, cloud computing, network slicing.

03 Application outcomes

1. After precise near-midpoint power sharing, user throughput shows noticeable gain. Power allocation and throughput gain trends are consistent. 2. For far-end users, after SSB boosting, throughput gains are significant and align with precise power allocation trends; however, without boosting the gain is not obvious. This indicates further study on boosting techniques is a worthwhile direction.

Case 2: Geely 5G + C2M Smart Chain Factory

Reporting unit: China Unicom Zhejiang Province Branch

Main business: Systems integration and equipment sales related to communications and information services; design and construction; technology development and services; technical consulting and training; sales and repair of mobile phones and accessories; production and sales of telecom cards; customer services; property leasing; directory publishing.

Partners: China Unicom Ningbo Branch; Ningbo Hangzhou Bay Geely Parts Co., Ltd.

01 Overview

Geely is a major automotive manufacturer that has pursued intelligent production and personalized customization. The Zeekr brand established an electric, intelligent ecosystem and achieved rapid delivery milestones. As an early "future factory" pilot, the Zeekr plant adopted advanced intelligent and automated equipment and reached high production throughput within a short period.

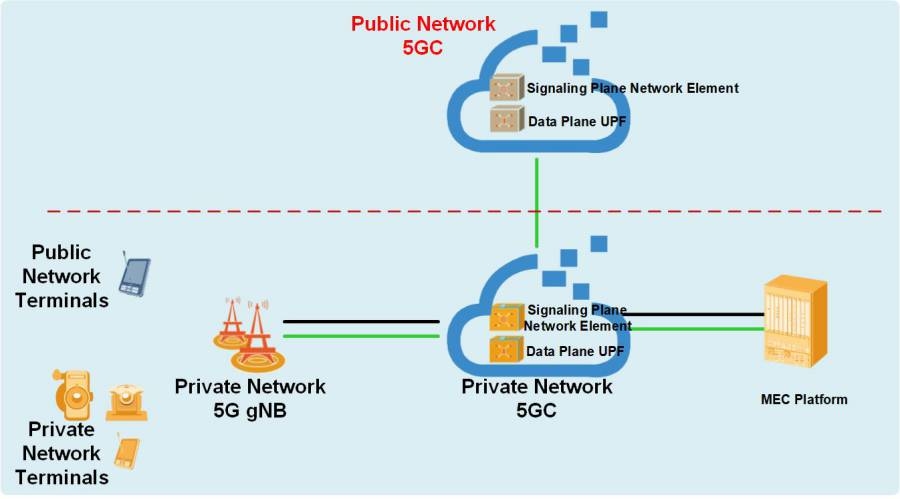

This project uses a 5G + MEC network architecture. A 5G gateway collects data from robots, PLCs, welding machines, AGVs, vision inspection cameras, MR/AR devices, and other equipment and transmits the data to the campus MEC. Local data return at the MEC ensures data remains on campus and provides low latency and high reliability. An IoT platform and big data platform deployed on MEC extract business value, enabling industrial apps that improve production efficiency and quality.

02 Key technologies

5G industry virtual private network, edge computing, network slicing, big data, cloud computing, artificial intelligence.

03 Application outcomes

1. Leveraging 5G's high bandwidth, low latency, and massive connectivity plus a simple, industrial-grade 5G gateway that supports multiple industrial protocols, the project piloted data collection from robots, PLCs, and welding systems and integrated AGV coordination. 2. Using 5G's low latency and high bandwidth, the project piloted MR/AR for assembly worker training and remote equipment maintenance, improving training efficiency and reducing repair time and cost.

Case 3: Boway 5G + Dual-MEC Future Factory for "Sky-Earth Dialogue"

Reporting unit: China Unicom Zhejiang Province Branch

Main business: Systems integration and equipment sales related to communications and information services; design and construction; technology development and services; technical consulting and training; sales and repair of mobile phones and accessories; production and sales of telecom cards; customer services; property leasing; directory publishing.

01 Overview

Ningbo Boway includes headquarters (Bomant), Yunlong, and Binhai campuses. The project completed 5G coverage and built a 5G private network to enable local traffic offload. Key needs identified during requirements analysis were:

- 1) Build a 5G + MEC enterprise private network: The MES system rollout across three campuses created urgent connectivity demands for production equipment, PDAs, barcode scanners, workshop PCs, and printers. Current campuses lack Wi-Fi and face packet loss and AP handover issues with traditional Wi-Fi, affecting usability.

- 2) Build an equipment data collection platform: Production-line equipment currently uses wired, traditional data-collection methods that are difficult and costly to deploy and maintain.

- 3) Build a unified industrial network: Multiple campuses had independent production networks interconnected by VPN or dark fiber, leading to dispersed access points, fragile interconnects, and inability to centrally manage.

The project objective is to build a Boway alloy 5G + smart factory using 5G and edge computing to create interconnected network infrastructure across three campuses, upgrade the enterprise intranet, and:

- 1) Construct a 5G + MEC enterprise intranet. Deploy a Boway 5G private network with four core networks: 5G private, surveillance, SCADA, and office, ensuring connectivity for MES data-collection terminals. MEC local offload keeps enterprise data in an internal loop, preventing data from leaving the campus and improving IT/OT integration and real-time data exchange.

- 2) Build a 5G + device data collection platform that replaces wired collection with 5G private network and industrial gateways, lowering investment and maintenance costs and providing complete device data for digital twins and predictive maintenance.

- 3) Establish a foundation for a faster, lighter, and more reliable factory network, improving intelligent and safe workshop production.

02 Key technologies

5G industry virtual private network, edge computing.

03 Application outcomes

1. Dual private networks ensure uninterrupted production: The project implemented a primary/backup dual 5G + MEC private network, moving beyond spot 5G applications to a comprehensive enterprise-level deployment. 2. 5G industrial internet integrated across production: This is an example of deeply integrating 5G private networks with production, covering industrial PLCs, PDAs, barcode scanners, cloud desktops, visual boards, and workshop PCs, advancing coordinated IT/OT operations. 3. Improved production efficiency: The solution can be replicated in process manufacturing, avoiding extensive wired and Wi-Fi deployment and addressing traditional networking pain points.

Case 4: Youngor 5G + Digital Twin Future Factory

Reporting unit: China Unicom Zhejiang Province Branch

Main business: Systems integration and equipment sales related to communications and information services; design and construction; technology development and services; technical consulting and training; sales and repair of mobile phones and accessories; production and sales of telecom cards; customer services; property leasing; directory publishing.

01 Overview

Youngor integrated AGV systems with warehouse, MES, and management systems over 5G to build a visual, traceable intelligent logistics system for apparel manufacturing. The project integrates MTM advanced customization, PLM product lifecycle management, and MES intelligent manufacturing, improving production efficiency by over 10%.

The project uses 5G's high bandwidth, low latency, high reliability, and massive connection capabilities combined with IoT, MEC edge computing, big data, and AI to enable OT and IT data interaction and remove traditional factory data silos.

Key achievements include:

- Cloud-edge collaboration and cross-province interconnection: Using a hybrid 5G private network and cloud networking to enable data interconnection among three cross-province production bases, meeting thousands of connection points and high-volume data exchange demands better than industrial Wi-Fi or 4G.

- 5G-enabled intelligent production: Phase one implemented seven 5G applications including fabric cutting, equipment management, automated lines, AGV material delivery, AI compliance monitoring, AI fabric inspection, and automatic inspection, achieving integrated sourcing, supply, and production coordination.

- Digital twin operations: Using digital twin and low-latency 5G, the project created a 1:1 virtual replica of the factory for capacity prediction, process perception, and production change support, enabling pre-deployment validation and simulated line operation to improve real-world production efficiency.

02 Key technologies

5G industry virtual private network, edge computing, network slicing, big data, cloud computing, artificial intelligence.

03 Application outcomes

After deployment, the system can collect data from over 3,000 sewing machines. Expected operational improvements include at least a 20% reduction in standard labor time, a 15% shorter material inventory cycle, at least a 10% faster order delivery cycle, at least a 50% shorter worker training cycle, and an overall 20% production efficiency increase. Estimated direct economic impacts include higher sales and profit improvements and a payback period around 1.2 years. The production gains also support market expansion and provide end-to-end order visibility via a customer-facing app for real-time order updates and personalized mass-customization synchronization across production lines.

Case 5: Goldcard Intelligent 5G Smart Gas System

Reporting unit: Goldcard Smart Group Co., Ltd.

Main business: Provider of digital energy products and solutions, covering digital gas, digital water, and energy metering.

01 Overview

Goldcard Smart is a manufacturer and solutions provider for gas metering and related systems. The project builds a 5G industry private network-enabled future factory to support flexible production line deployment and full-process quality inspection. It also implements a 5G "gas industry brain" that, using wide connectivity and intelligent safety technologies, enables on-site terminal access and intelligent analysis to support safe and stable city gas operations. Network deployment combines macro sites and indoor coverage to provide full 5G coverage of workshop lines, connecting production devices and deploying UPF at the campus using MEC for flexible line deployment.

The project realizes three main 5G application scenarios: 5G + gas industry brain, 5G + gas pipeline operation early-warning monitoring, and 5G + intelligent surveillance.

(1) 5G + Gas Industry Brain: Enterprise intelligent safety operations

The scenario uses a modular architecture to monitor end-to-cloud data in real time via 5G wide connectivity, integrating nine subsystems into an operational platform that covers intelligent safety, intelligent services, intelligent operations, and intelligent decision-making. This shifts safety management from passive defense to proactive perception, enabling consolidated monitoring and unified operations.

(2) 5G + Pipeline Operation Early-Warning Monitoring: Protect pipeline safety

This scenario aggregates data from 5G smart sensing terminals over a 5G wide-area network to monitor pipeline status in real time. Pipeline inspection efficiency improves by 25%, prevention of third-party construction damage increases by 70%, and hidden-hazard detection efficiency improves by 30%.

(3) 5G + Intelligent Surveillance: Unattended stations and gates

Given zero tolerance for safety violations at stations, this scenario uses 5G high bandwidth and low latency combined with AI to ensure HD video uplink and reduce safety violations by 70%. Robots enable 24/7 automatic inspection, and 5G transmits real-time data from smart meters, online chromatographs, and temperature/pressure collectors. Intrusion alarms are immediate and hazard detection timeliness reaches 100%.

02 Key technologies

5G industry virtual private network, 5G + edge computing, network slicing, positioning, big data, cloud computing.

03 Application outcomes

The 5G applications achieved three main effects: 1) Factory production efficiency increased, raising annual capacity from 6 million to 8 million units and improving overall productivity by 20% with product yield exceeding 99.5%. 2) Pipeline operation costs decreased: the 5G gas industry brain reduced inspection and dispatch costs by 20%. 3) Safety improved: the project met a 3-minute dispatch, 30-minute arrival standard, reduced construction safety accidents by 42%, and lowered gas leak and explosion incidents by 12%.

Case 6: Using 5G to Accelerate Xizi Clean Energy's Digital Transformation

Reporting unit: China Telecom Hangzhou Branch

Main business: Systems integration, technology development, technical services, information consulting, equipment sales, design and construction related to communications and information services; advertising design and publishing.

01 Overview

Xizi Clean Energy Equipment Manufacturing Co., Ltd., established in 1955, evolved from a leading waste-heat boiler manufacturer and is a foundational industrial enterprise in Hangzhou. Responding to local digitalization initiatives, Xizi has experimented with 5G and big data to support industrial internet transformations and energy-saving solutions, aiming to be a global supplier of energy-saving and environmental equipment and integrated energy-utilization solutions.

The project, developed jointly with China Telecom, creates a 5G future smart factory that connects production equipment via a 5G industrial private network. Combining 5G performance with IoT and device-monitoring technology improves process visibility, reduces manual intervention, and ensures accurate, timely production-data collection.

The design connects distributed personnel and devices to edge nodes via a customized 5G industrial private network. Core cloud and edge computing deploy three platforms: an AI safety management platform, an AR remote collaboration platform, and a digital new-energy platform. The cloud-edge integrated platforms provide:

- 1) Equipment management and predictive maintenance based on data collection;

- 2) Energy consumption management and analytics;

- 3) Production optimization through cloud-edge collaboration;

- 4) Cloud-based remote collaborative operations;

- 5) AI-based monitoring and analysis at edge nodes.

The platforms support multi-factory horizontal collaboration and vertical supply-chain interconnection for system-level management across the industrial group.

02 Key technologies

5G industry virtual private network, network slicing, big data, artificial intelligence.

03 Application outcomes

The project addresses shop-floor pain points in industrial manufacturing and supports digital transformation. Advantages of the deployment include: 1) meeting workshop-level bandwidth requirements, suitable for industrial park upgrades and security deployments with high replicability; 2) providing an integrated cloud+network+edge+platform solution from IaaS and PaaS to SaaS; 3) enabling rapid extension to multiple application scenarios via the operator's platform. The project's flexible deployment and multi-scenario applicability support wider digital transformation of traditional industrial enterprises.

ALLPCB

ALLPCB