Choosing the right PCB materials for smart watches is crucial for ensuring performance, durability, and compactness in these wearable devices. Whether you're an engineer or a designer, understanding smart watch PCB material selection can make or break your product's success. In this guide, we'll dive deep into the best materials, including flexible PCB materials, Rogers PCB for wearables, FR-4 alternatives for smartwatches, and high-frequency PCB materials, to help you make informed decisions.

At ALLPCB, we know the challenges of designing for small, high-performance devices like smart watches. That’s why we’ve crafted this comprehensive resource to walk you through every aspect of PCB material selection. Let’s explore the key considerations, material options, and practical tips to optimize your smart watch design.

Why PCB Material Selection Matters for Smart Watches

Smart watches are unique because they combine advanced electronics into a tiny, wearable form factor. The PCB (Printed Circuit Board) is the backbone of these devices, supporting components like sensors, processors, and wireless modules. Selecting the right material ensures:

- Compact Design: Materials must support miniaturization without sacrificing functionality.

- Durability: Wearables face constant movement and environmental stress, so materials need to withstand bending and impact.

- Signal Integrity: High-frequency signals for Bluetooth, Wi-Fi, and GPS require materials that minimize signal loss.

- Power Efficiency: Low dielectric loss materials help extend battery life, a critical factor for smart watches.

With these factors in mind, let’s break down the specific material options and their applications for smart watch PCBs.

Key Factors in Smart Watch PCB Material Selection

Before diving into specific materials, it’s important to understand the key criteria that influence smart watch PCB material selection. These factors will guide your choice based on the device’s requirements.

1. Flexibility and Form Factor

Smart watches often require PCBs that can bend or conform to curved designs. Traditional rigid materials may not work, so flexibility is a top priority. Materials should also support thin profiles, often less than 0.2 mm in thickness, to fit within tight spaces.

2. Thermal Management

Smart watches generate heat from processors and batteries. Materials with good thermal conductivity help dissipate heat, preventing damage to components and ensuring user comfort. A thermal conductivity of at least 0.3 W/m·K is often necessary for wearable applications.

3. High-Frequency Performance

Modern smart watches rely on high-frequency signals for wireless communication. Materials must have a low dielectric constant (Dk) and low dissipation factor (Df) to reduce signal loss. For instance, a Dk below 3.5 and a Df below 0.005 are ideal for frequencies above 2.4 GHz, commonly used in Bluetooth and Wi-Fi.

4. Cost and Manufacturability

While performance is critical, cost remains a factor. Materials should balance high performance with affordability, especially for mass-produced consumer devices like smart watches. Ease of manufacturing, such as compatibility with standard PCB processes, also plays a role.

With these criteria in mind, let’s explore the best material options for smart watch PCBs.

Top PCB Materials for Smart Watches

1. Flexible PCB Materials: Polyimide as the Go-To Choice

Flexible PCB materials are essential for smart watches due to their ability to bend and fit into irregular shapes. Among these, polyimide (PI) stands out as the most popular choice. Here’s why:

- High Flexibility: Polyimide can endure repeated bending without cracking, making it ideal for wearable designs.

- Thermal Stability: It withstands temperatures up to 260°C, protecting the PCB during soldering and operation.

- Thin Profile: Polyimide films can be as thin as 0.05 mm, supporting compact designs.

- Dielectric Properties: With a Dk of around 3.4 and Df of 0.002, it supports decent signal integrity for moderate frequencies.

Polyimide is often used in rigid-flex PCBs, combining rigid sections for component mounting with flexible sections for connectivity. This hybrid approach is perfect for smart watches, where space is limited, and durability is key.

2. Rogers PCB for Wearables: High-Frequency Excellence

For smart watches with advanced wireless features, Rogers PCB for wearables offers unmatched performance in high-frequency applications. Rogers materials, known for their low-loss properties, are often used in RF (radio frequency) and microwave circuits. Key benefits include:

- Low Dielectric Loss: Rogers laminates like RO4003C have a Dk of 3.38 and a Df as low as 0.0027 at 10 GHz, minimizing signal attenuation for Wi-Fi, GPS, and 5G signals.

- Stable Performance: These materials maintain consistent electrical properties across a wide temperature range (-40°C to 85°C), ideal for wearables exposed to varying conditions.

- Compact Integration: Their thin profiles support multilayer designs, crucial for packing complex circuits into small devices.

While Rogers materials are more expensive than standard options, they’re worth considering for premium smart watches where signal quality is non-negotiable. They’re often used in antenna designs and high-speed digital circuits within wearables.

3. FR-4 Alternatives for Smartwatches: Moving Beyond Traditional Materials

FR-4, a common PCB material made of woven fiberglass and epoxy resin, is widely used due to its low cost and decent mechanical strength. However, it falls short for smart watches due to its rigidity and poor high-frequency performance (Dk of 4.5 and Df of 0.02 at 1 MHz). Thankfully, there are FR-4 alternatives for smartwatches that better meet wearable needs:

- Isola IS410: A high-performance laminate with a Dk of 3.9 and improved thermal stability compared to standard FR-4. It’s a cost-effective step up for moderate-frequency applications.

- Nelco N4000-13: Offers a Dk of 3.7 and Df of 0.009, providing better signal integrity than FR-4 while maintaining manufacturability. It’s suitable for smart watches with basic wireless features.

- PTFE-Based Materials: Polytetrafluoroethylene (PTFE) composites offer a Dk as low as 2.2 and Df of 0.0009, excelling in high-frequency performance. They’re often combined with ceramic fillers for added stability.

These alternatives provide a middle ground between cost and performance, making them viable for smart watch designs that don’t require the premium properties of Rogers materials.

4. High-Frequency PCB Materials: Ensuring Signal Integrity

Smart watches rely heavily on wireless communication, making high-frequency PCB materials a critical consideration. Beyond Rogers laminates, other options include:

- Taconic RF-35: With a Dk of 3.5 and Df of 0.0018 at 1.9 GHz, this material is excellent for RF applications like Bluetooth antennas in smart watches.

- Arlon AD255C: Offers a Dk of 2.55 and Df of 0.0014, providing superior signal integrity for frequencies up to 10 GHz. It’s ideal for cutting-edge wearables with 5G connectivity.

- Ceramic Substrates: Used in niche applications, ceramics provide exceptional thermal conductivity (up to 30 W/m·K) and low dielectric loss, though they’re less flexible and more costly.

Choosing a high-frequency material depends on the specific wireless protocols your smart watch supports. For instance, a device with basic Bluetooth may not need the advanced properties of Arlon, while one with multiple connectivity options might benefit significantly.

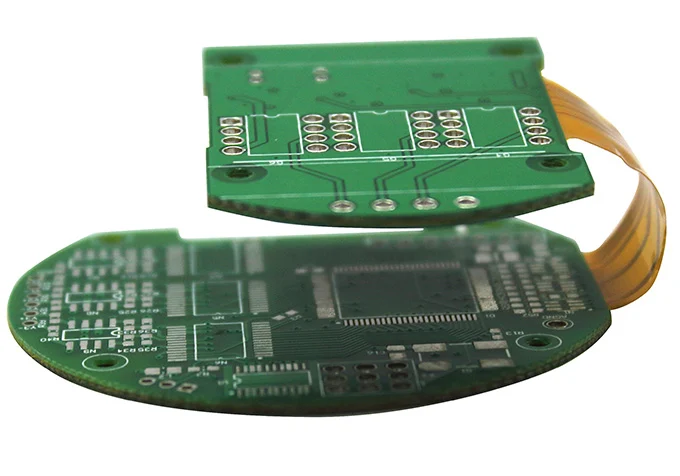

Rigid-Flex PCBs: The Best of Both Worlds for Smart Watches

One of the most effective solutions for smart watch design is the use of rigid-flex PCBs. These combine rigid sections for mounting components with flexible sections for connectivity, offering several advantages:

- Space Efficiency: Rigid-flex designs eliminate the need for bulky connectors, saving space in compact devices.

- Durability: Fewer connection points reduce the risk of failure due to vibration or movement, a common issue in wearables.

- Material Versatility: Rigid sections can use high-frequency materials like Rogers, while flexible sections use polyimide for adaptability.

Rigid-flex PCBs often use a combination of materials, with polyimide for flex layers and advanced laminates for rigid areas. This hybrid approach ensures both performance and reliability in smart watch applications.

Practical Tips for Selecting PCB Materials for Smart Watches

Now that we’ve covered the main material options, here are some actionable tips to guide your smart watch PCB material selection process:

- Define Your Frequency Needs: If your device uses high-frequency signals (above 2.4 GHz), prioritize low-loss materials like Rogers or Taconic. For lower frequencies, alternatives to FR-4 may suffice.

- Balance Cost and Performance: High-end materials improve performance but increase costs. Assess whether your target market justifies the expense or if a mid-range material meets the need.

- Consider Environmental Stress: Smart watches face moisture, temperature changes, and physical stress. Choose materials with good thermal stability and moisture resistance (e.g., polyimide or PTFE-based options).

- Test Prototypes: Before mass production, create prototypes with different materials to evaluate signal integrity, thermal performance, and durability under real-world conditions.

- Partner with Experts: Work with a trusted PCB provider like ALLPCB to access a wide range of materials and manufacturing expertise tailored to wearable designs.

Challenges in Smart Watch PCB Design and Material Solutions

Designing PCBs for smart watches comes with unique challenges. Here’s how material selection can address them:

- Miniaturization: Use thin, flexible materials like polyimide to fit complex circuits into small spaces without compromising functionality.

- Power Constraints: Low dielectric loss materials reduce energy waste, extending battery life—a key selling point for smart watches.

- Signal Interference: High-frequency materials with stable dielectric properties minimize crosstalk and interference, ensuring reliable communication.

By aligning material choices with these challenges, you can create a smart watch that excels in both performance and user experience.

Conclusion: Making the Right Choice with ALLPCB

Selecting the right PCB material for smart watches is a balancing act between performance, cost, and design constraints. Whether you opt for flexible PCB materials like polyimide, explore Rogers PCB for wearables for high-frequency needs, or consider FR-4 alternatives for smartwatches, each choice impacts your device’s success. Prioritizing high-frequency PCB materials ensures signal integrity, while rigid-flex designs offer durability and compactness.

At ALLPCB, we’re committed to helping you navigate smart watch PCB material selection with expert guidance and a wide range of material options. Our advanced manufacturing capabilities ensure that your smart watch design achieves optimal performance, no matter the complexity. Let us support your next wearable project with tailored solutions that meet your unique needs.

ALLPCB

ALLPCB