In the fast-evolving world of automotive and entertainment technology, high-power infotainment systems demand reliable and efficient components to handle intense electrical loads and heat. Metal Core Printed Circuit Boards (MCPCBs) stand out as a top solution for these challenges. If you’re wondering why MCPCBs are ideal for such applications, the answer lies in their superior thermal performance, durability, and ability to manage high currents effectively. In this blog, we’ll dive deep into the benefits of MCPCBs, focusing on metal core PCB thermal performance, aluminum PCB advantages, copper PCB alternatives, and their role in high-current applications.

Understanding Metal Core PCBs and Their Importance

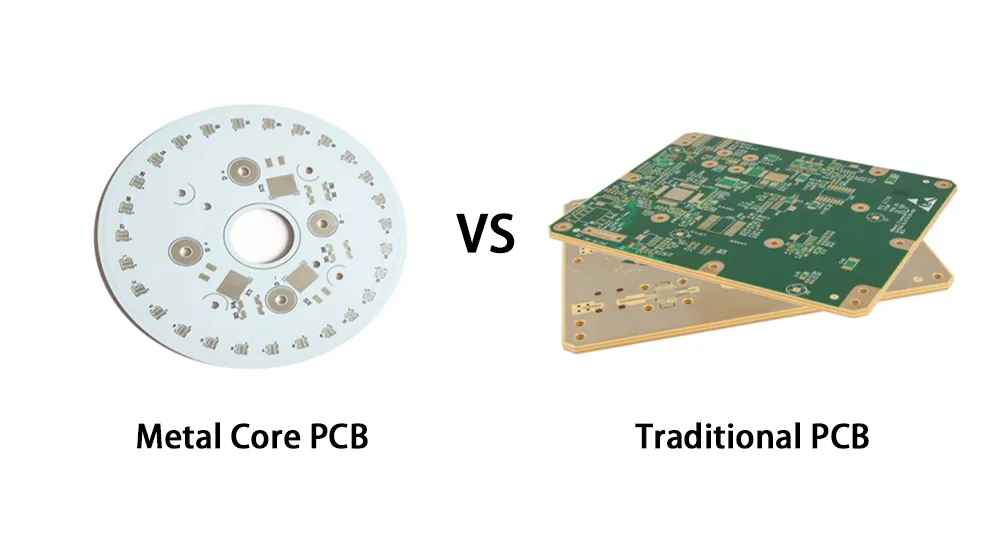

Metal Core PCBs are a specialized type of circuit board designed with a metal substrate, typically aluminum or copper, instead of the traditional fiberglass used in standard PCBs. This metal base acts as a heat sink, pulling heat away from critical components and ensuring the system runs smoothly even under heavy loads. In high-power infotainment systems, such as those found in modern vehicles with advanced multimedia displays, navigation, and connectivity features, managing heat and power is crucial for performance and longevity.

Unlike conventional boards, MCPCBs are built to handle the extreme conditions of high-power environments. Their ability to dissipate heat quickly makes them a game-changer for applications where overheating can lead to system failure or reduced lifespan. Let’s explore how these boards deliver unmatched advantages in such demanding scenarios.

Key Advantages of Metal Core PCBs in High-Power Infotainment Systems

1. Superior Metal Core PCB Thermal Performance

One of the standout features of MCPCBs is their exceptional thermal conductivity, which can be 5 to 10 times higher than traditional fiberglass-based boards. In high-power infotainment systems, components like power amplifiers, processors, and LED displays generate significant heat. If this heat isn’t managed properly, it can cause performance drops or even permanent damage.

For instance, aluminum-based MCPCBs have a thermal conductivity of around 1-2 W/mK, while copper-based options can reach up to 400 W/mK. This means heat is transferred away from sensitive components much faster, keeping operating temperatures low. In a vehicle’s infotainment system, where ambient temperatures can already be high, this thermal performance ensures reliability during long drives or in extreme weather conditions.

By reducing the need for additional cooling solutions like bulky heatsinks or fans, MCPCBs also help save space and lower overall system costs. This makes them a practical choice for compact, high-performance designs in automotive applications.

2. Aluminum PCB Advantages for Lightweight and Cost-Effective Designs

Aluminum is one of the most commonly used materials for MCPCBs, and for good reason. Aluminum PCB advantages include a lightweight structure, excellent thermal conductivity, and affordability compared to other metal options. In high-power infotainment systems, where weight reduction is often a priority for fuel efficiency in vehicles, aluminum-based boards offer a significant edge.

Aluminum MCPCBs are also highly durable, resistant to corrosion, and capable of withstanding mechanical stress. This durability translates to longer-lasting systems, even in the rugged environments of automotive use. Additionally, aluminum’s lower cost compared to copper makes it an attractive option for manufacturers looking to balance performance and budget.

For example, in a car’s multimedia control unit, an aluminum MCPCB can effectively manage the heat generated by high-definition display drivers while keeping the overall weight of the unit down. This balance of thermal efficiency and lightweight design is why aluminum MCPCBs are often the go-to choice for many engineers.

3. Copper PCB Alternatives for Maximum Thermal Conductivity

While aluminum is widely used, copper PCB alternatives are often considered when maximum thermal conductivity is the top priority. Copper has a much higher thermal conductivity than aluminum, making it ideal for applications where heat dissipation is critical. In high-power infotainment systems with extremely high current demands, such as premium audio systems with powerful amplifiers, copper MCPCBs can handle the thermal load more effectively.

However, copper is heavier and more expensive than aluminum, so it’s typically reserved for scenarios where the extra cost is justified by the need for superior performance. For instance, a copper MCPCB might be used in a high-end infotainment system powering a surround-sound setup with multiple high-wattage speakers. The trade-off between cost and performance often depends on the specific requirements of the application.

By offering both aluminum and copper options, MCPCBs provide flexibility for designers to choose the best material based on their project’s thermal and budgetary needs. This adaptability is a key reason why MCPCBs are so widely adopted in advanced electronic systems.

4. Ideal for High-Current Applications in Infotainment Systems

High-power infotainment systems often involve high-current applications, where components must handle significant electrical loads without overheating or failing. MCPCBs are uniquely suited for these conditions due to their robust construction and ability to support thick copper traces for current-carrying capacity.

For example, in a vehicle’s infotainment hub, power delivery to multiple subsystems—like touchscreen displays, wireless connectivity modules, and audio amplifiers—requires stable and efficient current management. MCPCBs can support copper foil thicknesses of up to 10 oz per square foot, allowing them to carry currents of several amperes without degrading. This capability ensures that all components receive the power they need without voltage drops or thermal stress.

Moreover, the metal core acts as a structural reinforcement, reducing the risk of board warping or cracking under high-current conditions. This durability is essential for maintaining system reliability over years of use in a vehicle’s demanding environment.

Why High-Power Infotainment Systems Need MCPCBs

Modern infotainment systems are more than just entertainment hubs; they integrate navigation, communication, vehicle diagnostics, and more into a single platform. This integration means higher power consumption, more heat generation, and greater complexity in circuit design. Here’s why MCPCBs are the perfect fit for these systems:

- Compact Design: With limited space in a vehicle’s dashboard, MCPCBs reduce the need for external cooling hardware, allowing for sleeker, more compact designs.

- Enhanced Reliability: By keeping components cool, MCPCBs extend the lifespan of infotainment systems, reducing maintenance costs for manufacturers and end-users.

- Energy Efficiency: Efficient heat dissipation means less energy is wasted as heat, improving the overall efficiency of the system.

- Support for Advanced Features: As infotainment systems incorporate more powerful processors and high-resolution displays, MCPCBs provide the thermal and electrical stability needed to support these advancements.

Practical Applications of MCPCBs in Infotainment Systems

MCPCBs are already making a big impact in various aspects of high-power infotainment systems. Here are a few real-world examples:

LED Backlighting for Displays: High-brightness LED arrays used in infotainment screens generate a lot of heat. Aluminum MCPCBs are often used to manage this heat, ensuring consistent brightness and preventing screen burnout.

Audio Amplifiers: Premium sound systems in vehicles rely on powerful amplifiers that draw significant current. Copper MCPCBs help dissipate the heat from these amplifiers, maintaining sound quality and preventing distortion.

Power Supply Units: The power supply modules in infotainment systems must handle high currents to support multiple subsystems. MCPCBs ensure stable power delivery without overheating, even during peak usage.

These applications highlight the versatility of MCPCBs in addressing the diverse challenges of high-power infotainment systems, making them an indispensable component for modern automotive electronics.

Design Considerations for Using MCPCBs in Infotainment Systems

While MCPCBs offer numerous benefits, there are a few design considerations to keep in mind to maximize their performance:

- Material Selection: Choose between aluminum and copper based on thermal requirements, weight constraints, and budget. Aluminum is lighter and cheaper, while copper offers better heat dissipation.

- Dielectric Layer Thickness: The insulating layer between the metal core and copper traces affects thermal conductivity. A thinner dielectric layer improves heat transfer but may impact electrical isolation.

- Board Thickness: Thicker boards provide better structural support for high-current applications but may increase weight. Typical MCPCB thicknesses range from 0.8 mm to 3.2 mm, depending on the design needs.

- Thermal Vias: Adding thermal vias can further enhance heat dissipation by creating direct pathways for heat to move from components to the metal core.

By carefully considering these factors during the design phase, engineers can optimize MCPCBs for the specific demands of high-power infotainment systems.

Conclusion: Why MCPCBs Are the Future of Infotainment Systems

As infotainment systems in vehicles become more advanced, the need for reliable, high-performance components like Metal Core PCBs becomes undeniable. With their outstanding metal core PCB thermal performance, the lightweight and cost-effective aluminum PCB advantages, the high-conductivity copper PCB alternatives, and their suitability for high-current applications, MCPCBs are uniquely equipped to meet the challenges of modern automotive electronics.

Whether it’s keeping a high-definition display cool, powering a premium audio system, or ensuring stable power delivery, MCPCBs provide the thermal management and durability needed for cutting-edge infotainment systems. For engineers and manufacturers looking to push the boundaries of what’s possible in vehicle technology, integrating MCPCBs into their designs is a smart and forward-thinking choice.

By leveraging the benefits of MCPCBs, the automotive industry can continue to deliver innovative, reliable, and efficient infotainment solutions that enhance the driving experience. As technology evolves, MCPCBs will undoubtedly play a central role in shaping the future of high-power electronics in vehicles and beyond.

ALLPCB

ALLPCB