In the world of printed circuit board (PCB) design and manufacturing, achieving effective traceability and identification is crucial for quality control and efficiency. One key element in this process is the use of silk screen color for identification, component tracking, version control, and serial numbers. But what are the best practices for using silk screen color to enhance PCB traceability? This blog post dives deep into the topic, offering practical tips and insights on leveraging silk screen color for better PCB management. Whether you're an engineer or a manufacturer, you'll find actionable advice to improve your designs and production processes with a focus on PCB traceability silkscreen techniques.

What Is PCB Silkscreen and Why Does It Matter for Traceability?

PCB silkscreen refers to the layer of text and symbols printed on the surface of a circuit board using non-conductive ink. This layer typically includes information like component labels, reference designators, test points, polarity indicators, and even serial numbers or version codes. Silkscreen is not just about aesthetics; it plays a vital role in assembly, testing, and troubleshooting by making critical information visible and accessible.

When it comes to PCB traceability, silkscreen serves as a visual tool to track components, identify board versions, and ensure each unit can be traced back through the production process. Using silk screen color for identification adds another layer of clarity, helping to differentiate between boards, highlight specific information, and reduce errors during manufacturing and maintenance.

The Role of Silk Screen Color in PCB Traceability

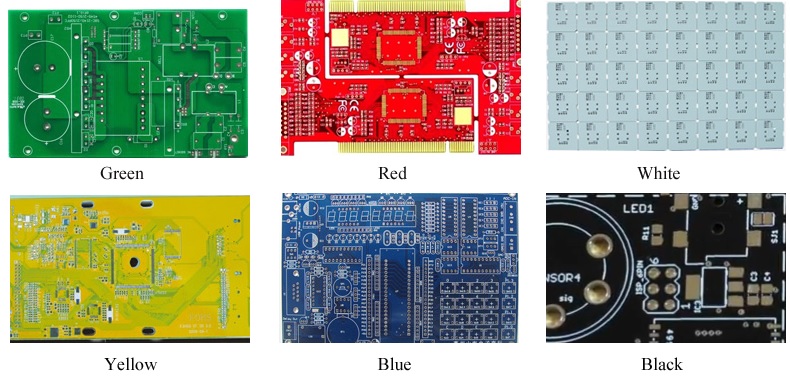

While the most common silkscreen color is white, due to its high contrast against the typical green or blue solder mask, other colors can be used strategically for specific purposes. Silk screen color for component tracking, version control, and serial numbers can significantly improve the readability and organization of information on a PCB. Let’s explore how color choices impact traceability and identification.

1. Enhancing Visibility with Color Contrast

Choosing the right silk screen color for identification starts with ensuring visibility. A high contrast between the silkscreen ink and the solder mask is essential for readability. For instance, white ink on a green or black solder mask stands out clearly under various lighting conditions. However, if a PCB uses a lighter solder mask, such as yellow or white, darker silkscreen colors like black or dark blue may be more effective.

Visibility becomes even more critical when dealing with small text or intricate symbols. According to industry standards, silkscreen text should ideally be at least 0.15 mm in line width and 1.5 mm in height to remain legible. Pairing this with the right color ensures that even tiny markings, like serial numbers, are easily readable during inspection or repair.

2. Using Silk Screen Color for Component Tracking

Component tracking is a cornerstone of PCB traceability. By assigning specific silk screen colors to different types of components or sections of the board, manufacturers can quickly identify parts during assembly and troubleshooting. For example, using red silkscreen for high-voltage components and blue for low-voltage ones can help technicians spot critical areas at a glance, reducing the risk of errors.

This approach also aids in quality control. If a batch of boards shows recurring issues with a specific component, a distinct color can help trace the problem back to a particular supplier or production run. This targeted use of silk screen color for component tracking streamlines root cause analysis and improves overall production efficiency.

3. Implementing Silk Screen Color for Version Control

Version control is another area where silkscreen color can make a significant difference. As PCB designs evolve through multiple revisions, it’s common to have several versions of a board in circulation. Using silk screen color for version control allows manufacturers and engineers to distinguish between revisions without needing to consult documentation.

For instance, a board’s first version might use green silkscreen for version numbers, while the second version switches to yellow, and the third to red. This visual cue helps assembly teams and end-users immediately recognize which iteration they are handling. This method is especially useful in high-mix, low-volume production environments where multiple board versions may be processed simultaneously.

4. Leveraging Silk Screen Color for Serial Numbers

Serial numbers are essential for traceability, allowing each PCB to be uniquely identified throughout its lifecycle. Using silk screen color for serial numbers can make them stand out from other markings, ensuring they are easy to locate and read. A distinct color, such as bright yellow or orange, can draw attention to the serial number, especially on crowded boards with numerous markings.

Additionally, serial numbers in a specific color can indicate different production batches or manufacturing locations. For example, a blue serial number might signify boards produced in one facility, while a red one indicates another. This color-coding system enhances traceability by providing immediate visual information about a board’s origin.

Best Practices for Using Silk Screen Color in PCB Traceability

While the benefits of using silk screen color for PCB traceability are clear, implementing it effectively requires careful planning and adherence to best practices. Below are actionable tips to ensure your silkscreen design maximizes clarity and functionality.

1. Prioritize Readability Over Aesthetics

While colorful silkscreen markings can look appealing, the primary goal is functionality. Always choose colors that provide high contrast with the solder mask and are legible under typical working conditions. Avoid overly bright or neon colors that may fade over time or cause eye strain during prolonged inspection.

2. Standardize Color Coding Across Projects

Consistency is key to effective traceability. Develop a standardized color-coding system for your PCBs and apply it across all projects. For example, always use red for critical warnings, blue for version numbers, and yellow for serial numbers. Document this system and share it with your design and manufacturing teams to avoid confusion.

3. Limit the Number of Colors Used

Using too many colors on a single board can create visual clutter and defeat the purpose of color coding. Stick to a maximum of 3-4 distinct colors to keep the silkscreen clean and organized. Reserve each color for a specific purpose, such as component tracking, version control, or serial numbers, to maintain clarity.

4. Consider Manufacturing Capabilities

Not all PCB manufacturers support multi-color silkscreen printing, and those that do may charge a premium for it. Before finalizing your design, confirm the capabilities and costs with your manufacturing partner. If multi-color printing isn’t feasible, focus on strategic placement and text design to achieve similar traceability benefits with a single color.

5. Test Visibility Under Different Conditions

Before mass production, test your silkscreen design under various lighting conditions and viewing angles to ensure all markings are visible. For instance, markings that look clear under bright factory lighting may be harder to read in dim repair shop environments. Adjust colors and text sizes as needed based on these tests.

6. Integrate Silkscreen with Digital Traceability Tools

While silkscreen color enhances visual traceability, it’s most effective when combined with digital tools like barcodes or QR codes. Printing a scannable code next to a colored serial number, for example, allows for both manual and automated tracking. This hybrid approach ensures maximum traceability across different stages of production and usage.

Challenges and Solutions in Using Silk Screen Color for Traceability

Despite its advantages, using silk screen color for PCB traceability comes with certain challenges. Understanding these obstacles and how to overcome them can help you implement a more effective system.

Challenge 1: Color Fading Over Time

Silkscreen ink can fade due to exposure to heat, chemicals, or UV light, especially in harsh operating environments. This can make colored markings less visible and reduce their effectiveness for traceability.

Solution: Use high-quality, UV-resistant inks and apply a protective coating over the silkscreen layer if the PCB will be exposed to harsh conditions. Additionally, choose colors that are less prone to fading, such as darker shades, for critical information like serial numbers.

Challenge 2: Limited Space on Small Boards

On compact PCBs, there may not be enough space to include detailed silkscreen markings or multiple colors without cluttering the design.

Solution: Prioritize the most critical information, such as serial numbers or version codes, and use a single color with varying text styles (e.g., bold or italic) to differentiate data. Alternatively, place detailed markings on less crowded areas of the board or use a separate documentation sheet for reference.

Challenge 3: Cost of Multi-Color Printing

Multi-color silkscreen printing can increase production costs, especially for small runs or prototypes where budget constraints are a concern.

Solution: Reserve multi-color printing for high-value or high-volume projects where the benefits of enhanced traceability justify the cost. For other projects, use a single color with clear labeling conventions to achieve similar results.

Conclusion: Maximizing PCB Traceability with Strategic Silkscreen Color Use

Incorporating silk screen color into your PCB design is a powerful way to enhance traceability, streamline manufacturing, and improve quality control. By using silk screen color for identification, component tracking, version control, and serial numbers, you can create boards that are easier to assemble, test, and maintain. The key lies in choosing the right colors, standardizing their use, and balancing functionality with manufacturing constraints.

Whether you're color-coding components to prevent assembly errors or highlighting serial numbers for batch tracking, a well-thought-out PCB traceability silkscreen strategy can save time and reduce errors across the board’s lifecycle. By following the best practices outlined in this post, you can ensure that your silkscreen design not only looks good but also delivers real value to your production process.

ALLPCB

ALLPCB