In the fast-evolving world of missile guidance systems, traditional FR-4 substrates often fall short of meeting the stringent demands for high performance, reliability, and thermal management. So, what are the advanced PCB substrates that can power next-gen missile guidance systems? Materials like ceramic PCBs, metal core PCBs, PTFE-based substrates, composite materials, and thermal clad substrates offer superior capabilities for handling extreme conditions, high-frequency signals, and intense power requirements. In this blog, we dive deep into these cutting-edge substrates, exploring their unique properties and how they support the critical needs of missile guidance technology.

Why FR-4 Falls Short for Missile Guidance Systems

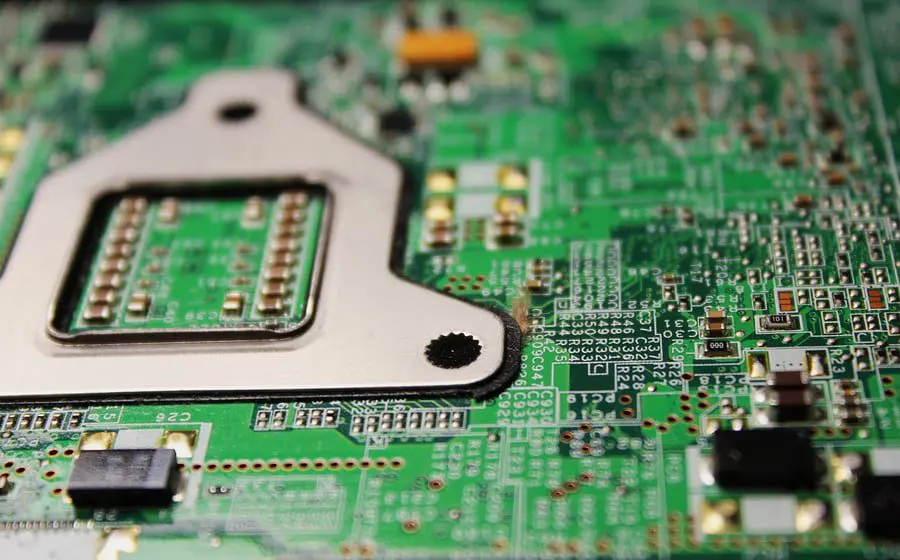

FR-4, a widely used PCB substrate made of fiberglass and epoxy resin, is affordable and versatile for many applications. However, missile guidance systems operate in harsh environments with high temperatures, intense vibrations, and the need for precise signal integrity at radio frequencies (RF). FR-4 struggles with thermal conductivity (typically around 0.3 W/m·K), has higher signal loss at RF ranges, and lacks the mechanical strength needed for extreme conditions. These limitations push engineers to explore advanced materials tailored for such demanding applications.

Advanced PCB Substrates: Meeting the Demands of Missile Guidance

Missile guidance systems require PCBs that can handle high power, maintain signal integrity for RF applications, and resist thermal and mechanical stress. Below, we explore five advanced substrates that are shaping the future of this technology, focusing on their properties, benefits, and specific use cases.

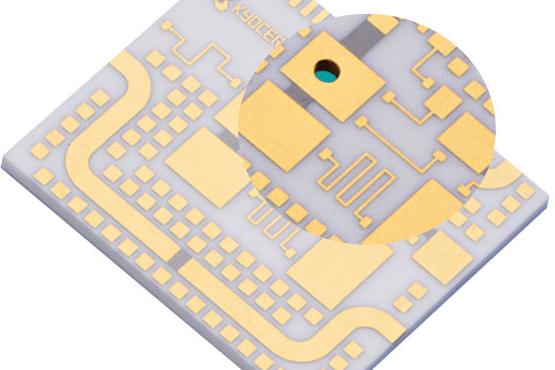

1. Ceramic PCB for Missile Guidance: Unmatched Thermal and Electrical Performance

Ceramic PCBs are a top choice for missile guidance systems due to their exceptional thermal conductivity and electrical insulation properties. Made from materials like alumina (Al2O3) or aluminum nitride (AlN), ceramic substrates can achieve thermal conductivity values ranging from 20 to 170 W/m·K, far surpassing FR-4. This allows them to dissipate heat effectively in high-power circuits, a critical need for guidance systems where overheating can lead to failure.

Additionally, ceramic PCBs offer low dielectric loss, making them ideal for high-frequency applications. With dielectric constants typically between 8 and 10, they ensure minimal signal distortion, which is vital for the precision required in guidance control. Their ability to withstand temperatures up to 1000°C also makes them suitable for the extreme conditions encountered during missile flight.

Key Benefits for Missile Guidance:

- High thermal conductivity for heat dissipation.

- Low signal loss for accurate RF communication.

- Durability in extreme temperatures and vibrations.

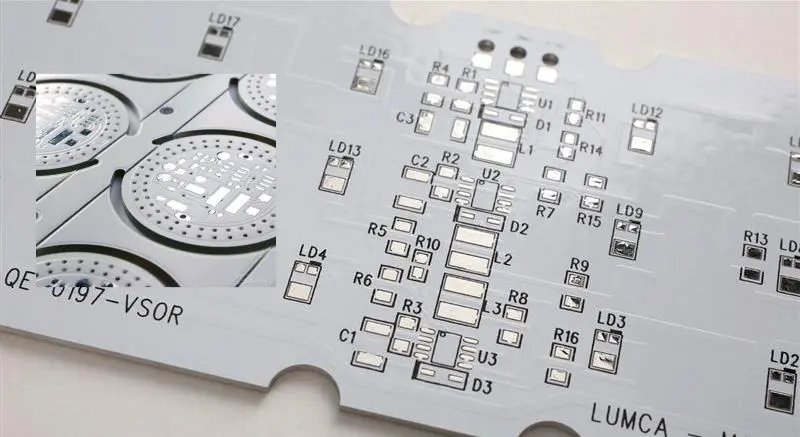

2. Metal Core PCB for High Power: Strength and Heat Management

Metal core PCBs (MCPCBs) are engineered with a metal base, usually aluminum or copper, to provide superior heat dissipation. With thermal conductivity values between 1 and 4 W/m·K for aluminum-based MCPCBs, they are well-suited for high-power applications in missile guidance systems, such as power amplifiers and control circuits. The metal core acts as a heat sink, pulling heat away from sensitive components and preventing thermal runaway.

Beyond thermal performance, metal core PCBs offer excellent mechanical strength, resisting the intense vibrations and shocks experienced during missile launch and flight. This durability ensures long-term reliability in mission-critical scenarios where failure is not an option.

Key Benefits for Missile Guidance:

- Enhanced heat dissipation for high-power components.

- Robust structure to withstand mechanical stress.

- Cost-effective compared to some advanced materials.

3. PTFE PCB for RF Applications: Precision in High-Frequency Signals

Polytetrafluoroethylene (PTFE) PCBs are widely recognized for their low dielectric constant (typically around 2.1 to 2.5) and minimal signal loss, making them a go-to choice for RF applications in missile guidance systems. These systems rely on high-frequency signals for communication, radar, and navigation, where even small signal distortions can lead to catastrophic errors. PTFE substrates ensure clean, reliable signal transmission, even at frequencies exceeding 10 GHz.

PTFE materials also resist moisture and chemicals, which is crucial for missiles operating in diverse environmental conditions. While they are more expensive than traditional substrates, their performance in RF circuits justifies the cost for precision-driven applications.

Key Benefits for Missile Guidance:

- Low dielectric loss for high-frequency signal integrity.

- Resistance to environmental factors like humidity.

- Stable performance across a wide temperature range.

4. Composite PCB Materials for Missile Guidance: Balancing Performance and Cost

Composite PCB materials, often a blend of epoxy, fiberglass, and other reinforcements, are engineered to offer a balance between performance and cost. These substrates can be customized to meet specific needs, such as improved thermal conductivity (up to 1.5 W/m·K in some formulations) or enhanced mechanical strength. For missile guidance systems, composite materials are often used in less critical areas where extreme performance isn’t required but reliability remains essential.

One advantage of composite substrates is their versatility. By adjusting the composition, manufacturers can tailor properties like dielectric constant (typically 3.5 to 4.5) and thermal expansion to match the needs of specific guidance system components, making them a flexible option for hybrid designs.

Key Benefits for Missile Guidance:

- Customizable properties for specific applications.

- Cost-effective compared to ceramic or PTFE substrates.

- Good balance of thermal and mechanical performance.

5. Thermal Clad PCB Substrate: Optimized Heat Dissipation for Reliability

Thermal clad PCB substrates are designed with a thermally conductive dielectric layer bonded to a metal base, offering a highly effective solution for heat management. With thermal conductivity often exceeding 2 W/m·K, these substrates excel at transferring heat away from critical components, ensuring stable operation in the high-stress environment of missile guidance systems.

Thermal clad substrates are particularly useful in power-dense circuits where space is limited, and heat buildup is a constant concern. Their ability to maintain low operating temperatures helps extend the lifespan of electronic components, a vital factor for systems that must perform flawlessly during critical missions.

Key Benefits for Missile Guidance:

- Superior heat dissipation in compact designs.

- Enhanced reliability for power-intensive circuits.

- Compatibility with high-density layouts.

Choosing the Right Substrate for Missile Guidance Systems

Selecting the appropriate PCB substrate for missile guidance systems depends on several factors, including the specific application, environmental conditions, and budget constraints. Here’s a quick guide to help engineers make informed decisions:

- High-Frequency Needs: Opt for PTFE PCBs to ensure signal integrity in RF applications.

- High-Power Circuits: Choose metal core or thermal clad substrates for effective heat dissipation.

- Extreme Conditions: Use ceramic PCBs for unmatched thermal and mechanical durability.

- Cost-Sensitive Designs: Consider composite materials for a balance of performance and affordability.

By aligning the substrate choice with the system’s requirements, engineers can optimize performance and reliability, ensuring mission success under the toughest conditions.

Future Trends in PCB Substrates for Missile Guidance

The field of PCB substrates is advancing rapidly, driven by the increasing complexity of missile guidance systems. Emerging materials, such as graphene-based composites, promise even higher thermal conductivity and lighter weight, potentially revolutionizing design possibilities. Additionally, advancements in manufacturing techniques are making high-performance substrates more accessible, reducing costs without compromising quality.

Another trend is the integration of hybrid substrates, combining the benefits of materials like ceramic and PTFE in a single board. This approach allows for tailored performance in different sections of the PCB, addressing diverse needs within one system. As technology progresses, we can expect substrates to become even more specialized, meeting the ever-growing demands of next-gen missile guidance.

Conclusion: Powering the Future of Missile Guidance with Advanced Substrates

As missile guidance systems continue to push the boundaries of technology, the role of advanced PCB substrates becomes increasingly critical. Moving beyond traditional FR-4, materials like ceramic PCBs, metal core PCBs, PTFE substrates, composite materials, and thermal clad substrates provide the performance, reliability, and durability needed for mission-critical applications. Whether it’s handling high-frequency signals, managing intense power loads, or withstanding extreme environments, these substrates are paving the way for the next generation of guidance technology.

At ALLPCB, we are committed to supporting engineers with cutting-edge solutions for even the most demanding projects. By understanding the unique properties of these advanced substrates, you can design systems that meet the highest standards of precision and performance. Let’s build the future of missile guidance technology together with the right materials for every challenge.

ALLPCB

ALLPCB