In the fast-evolving world of electronics, managing heat effectively is a critical challenge. Aluminum PCBs have emerged as a promising solution for thermal management, offering superior heat dissipation compared to traditional materials. But are they truly the future of thermal management in printed circuit board technology? In short, yes—aluminum PCBs are poised to play a significant role due to their excellent thermal conductivity, durability, and suitability for high-power applications. This blog dives deep into why aluminum PCBs are gaining traction, exploring aluminum PCB market trends, the future of PCB technology, thermal management solutions, advanced PCB materials, and innovations in PCB design.

What Are Aluminum PCBs and Why Do They Matter?

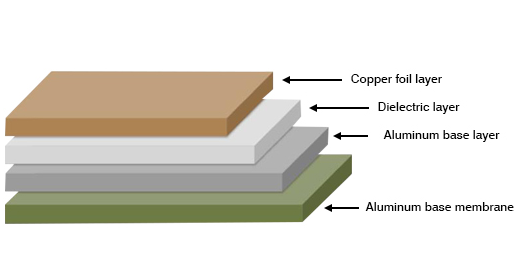

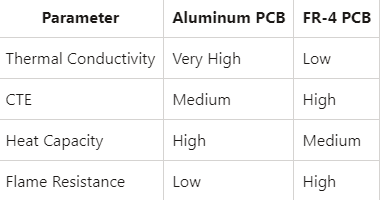

Aluminum PCBs, also known as metal core PCBs (MCPCBs), are circuit boards with a metal base layer, typically aluminum, instead of the standard FR4 material. This metal layer acts as a heat sink, efficiently drawing heat away from critical components. With thermal conductivity ranging from 1 to 2 W/m·K (compared to FR4’s 0.3 W/m·K), aluminum PCBs are ideal for applications where heat dissipation is a priority, such as LED lighting, power supplies, and automotive electronics.

The importance of aluminum PCBs lies in their ability to enhance the reliability and lifespan of electronic devices. Excessive heat can degrade components, reduce performance, and even cause system failures. By addressing these issues, aluminum PCBs are becoming a go-to choice for engineers working on high-power and high-temperature projects.

Aluminum PCB Market Trends: A Growing Demand

The demand for aluminum PCBs is on the rise, driven by the increasing need for efficient thermal management in various industries. According to recent industry insights, the global aluminum PCB market is expected to grow at a significant compound annual growth rate (CAGR) over the next decade, reaching substantial market value by the early 2030s. Key sectors fueling this growth include consumer electronics, automotive, and industrial automation.

In regions like Asia Pacific, where electronics manufacturing hubs are concentrated, the adoption of aluminum PCBs is particularly strong. This trend is supported by the region’s focus on producing high-performance devices like smartphones, laptops, and electric vehicle (EV) systems, all of which require robust thermal solutions. North America and Europe are also seeing steady growth, especially in automotive and renewable energy applications where heat management is critical.

One major driver of this market trend is the shift toward miniaturization. As devices become smaller and more powerful, managing heat in confined spaces becomes harder. Aluminum PCBs offer a compact yet effective solution, making them a preferred choice for modern designs.

Thermal Management Solutions: How Aluminum PCBs Excel

Thermal management is all about keeping electronic components within safe operating temperatures. Aluminum PCBs stand out in this area due to their unique structure. The aluminum base layer provides a direct path for heat to escape, reducing the risk of hotspots. This is especially important in high-power applications like LED lighting, where heat buildup can reduce brightness and lifespan. For example, an LED module on an aluminum PCB can dissipate heat up to five times faster than on a standard FR4 board.

Another advantage is their ability to handle higher current loads without overheating. In power converters and motor controllers, aluminum PCBs can manage currents of 10A or more while maintaining stable temperatures. This capability not only improves performance but also reduces the need for additional cooling components like fans or heat sinks, saving space and cost.

Moreover, aluminum PCBs are often paired with advanced dielectric materials that further enhance thermal performance. These materials, with thermal conductivities up to 3 W/m·K, create a barrier between the aluminum base and copper traces while still allowing efficient heat transfer. This combination makes aluminum PCBs a versatile and powerful thermal management solution.

The Future of PCB Technology: Where Aluminum Fits In

Looking ahead, the future of PCB technology is shaped by the need for higher performance, sustainability, and adaptability. Aluminum PCBs align well with these goals. As industries push for greener solutions, the recyclability of aluminum offers an environmental advantage over other materials. Additionally, their durability in harsh conditions—such as high humidity or extreme temperatures—makes them suitable for applications in automotive and aerospace sectors.

One exciting development in PCB technology is the integration of aluminum PCBs with emerging trends like 5G and Internet of Things (IoT) devices. These technologies demand high-speed signal transmission and low thermal noise, both of which benefit from the stability provided by aluminum’s heat dissipation properties. For instance, in 5G base stations, aluminum PCBs can manage the heat generated by high-frequency signals, ensuring consistent performance.

Furthermore, advancements in manufacturing processes are making aluminum PCBs more accessible. Improved techniques for bonding dielectric layers and etching copper traces are reducing production costs, which could lead to wider adoption across mid-range and budget-friendly products in the coming years.

Advanced PCB Materials: Why Aluminum Stands Out

While FR4 remains the standard for many low-cost applications, advanced PCB materials like aluminum are gaining ground in high-performance scenarios. Aluminum’s thermal conductivity is a key differentiator, but it also offers other benefits, such as lightweight construction and resistance to mechanical stress. These properties are crucial in industries like automotive, where weight reduction directly impacts fuel efficiency.

Compared to other metal core materials like copper, aluminum strikes a balance between performance and cost. Copper has higher thermal conductivity (around 400 W/m·K), but it’s heavier and more expensive. Aluminum, with a conductivity of 200 W/m·K, provides a cost-effective alternative without sacrificing too much performance. This makes it an attractive option for large-scale production.

In addition, aluminum PCBs can be combined with innovative materials like ceramic-filled dielectrics for even better thermal and electrical isolation. These hybrid designs are pushing the boundaries of what’s possible, allowing engineers to tackle more complex challenges in power electronics and renewable energy systems.

Innovations in PCB Design: Leveraging Aluminum for Better Results

Innovations in PCB design are unlocking new possibilities for aluminum-based boards. One such innovation is the use of multi-layer aluminum PCBs, which combine the thermal benefits of aluminum with the complexity of multi-layer circuits. These designs are ideal for compact devices that require both high power and intricate wiring, such as advanced medical equipment.

Another area of progress is in surface treatments and finishes. New coating technologies are improving the corrosion resistance of aluminum PCBs, making them suitable for outdoor and marine applications. For example, anodized aluminum surfaces can withstand salt spray tests for over 1,000 hours, ensuring long-term reliability in tough environments.

Design software advancements are also playing a role. Modern tools allow engineers to simulate heat flow and optimize the placement of components on aluminum PCBs before production. This reduces trial-and-error costs and ensures that thermal management is built into the design from the start. By integrating simulation with real-world testing, designers can achieve temperature reductions of up to 20% in critical areas.

Challenges and Limitations of Aluminum PCBs

Despite their many advantages, aluminum PCBs are not without challenges. One limitation is their higher cost compared to standard FR4 boards. While manufacturing improvements are narrowing this gap, aluminum PCBs can still be 20-30% more expensive, which may deter their use in cost-sensitive projects.

Another issue is their rigidity. Unlike flexible PCBs, aluminum boards are less adaptable to curved or dynamic designs, limiting their use in certain wearable or foldable devices. Additionally, while aluminum is excellent for heat dissipation, it’s not as effective for electrical insulation, requiring careful selection of dielectric layers to prevent short circuits.

However, ongoing research and development are addressing these drawbacks. For instance, hybrid PCBs that combine aluminum with flexible substrates are being explored to offer the best of both worlds. As these solutions mature, the scope of aluminum PCB applications will likely expand.

Applications of Aluminum PCBs in Modern Industries

Aluminum PCBs are already making a significant impact across various industries. In LED lighting, they’re widely used to manage the heat generated by high-brightness LEDs, ensuring consistent output and longevity. A typical LED driver board on aluminum can operate at temperatures up to 85°C without performance loss, compared to just 60°C on FR4.

In the automotive sector, aluminum PCBs are critical for electric vehicle battery management systems (BMS). These systems generate substantial heat during charging and discharging cycles, and aluminum’s ability to handle thermal loads of over 100 W ensures safety and efficiency. Similarly, in renewable energy, solar inverters rely on aluminum PCBs to dissipate heat from power conversion circuits.

Industrial automation is another area where aluminum shines. Robotics and motor control systems often operate in high-temperature environments, and aluminum PCBs provide the durability and thermal stability needed for continuous operation. Their ability to withstand vibrations and shocks also adds to their appeal in such settings.

Conclusion: The Road Ahead for Aluminum PCBs

Aluminum PCBs are proving to be a game-changer in thermal management, offering unmatched heat dissipation, durability, and versatility. As aluminum PCB market trends show steady growth, and with the future of PCB technology leaning toward high-performance and sustainable solutions, it’s clear that aluminum will play a central role. From advanced PCB materials to innovations in PCB design, the evolution of aluminum-based boards is paving the way for more reliable and efficient electronics.

For engineers and designers, the message is clear: aluminum PCBs are not just a trend but a long-term solution for tackling thermal challenges. Whether you’re working on LED systems, automotive electronics, or industrial automation, incorporating aluminum into your designs can elevate performance and reliability. As technology advances, we can expect even more exciting developments in thermal management solutions, with aluminum PCBs leading the charge.

ALLPCB

ALLPCB