Selecting a reliable multi-layer PCB assembly partner is crucial for ensuring the success of your electronic projects. To make the right choice, focus on evaluating their PCB manufacturing capabilities, experience with quality PCB assembly, relevant PCB certifications, and the range of PCB assembly services they offer. Partnering with a trusted PCB manufacturer can save time, reduce costs, and guarantee high-performance boards for complex applications.

In this comprehensive guide, we’ll walk you through the essential steps and factors to consider when choosing a multi-layer PCB assembly partner. From technical expertise to quality control processes, we’ll cover everything you need to know to make an informed decision that aligns with your project needs.

Why Choosing the Right Multi-Layer PCB Assembly Partner Matters

Multi-layer PCBs are the backbone of modern electronics, used in everything from smartphones to medical devices and aerospace systems. These boards, often consisting of 4 to 16 layers or more, handle high-density components and complex circuits with tight impedance control (typically within ±10% tolerance, e.g., 50 ohms for high-speed signals). A single defect or delay in assembly can lead to costly redesigns or project setbacks.

Partnering with a reliable PCB manufacturer ensures that your multi-layer boards meet stringent performance and reliability standards. A capable partner not only provides quality PCB assembly but also streamlines production, reduces errors, and supports your project from prototype to full-scale manufacturing.

Key Factors to Consider When Selecting a PCB Assembly Partner

Finding the right partner for PCB assembly services requires a detailed evaluation of several critical factors. Below, we break down the most important aspects to guide your decision-making process.

1. Assess Their PCB Manufacturing Capabilities

The foundation of a reliable multi-layer PCB assembly partner lies in their PCB manufacturing capabilities. Not all manufacturers can handle the complexity of multi-layer boards, which often require precise layer stacking, blind and buried vias, and controlled impedance for signal integrity (e.g., maintaining 100 ohms for differential pairs in high-speed designs).

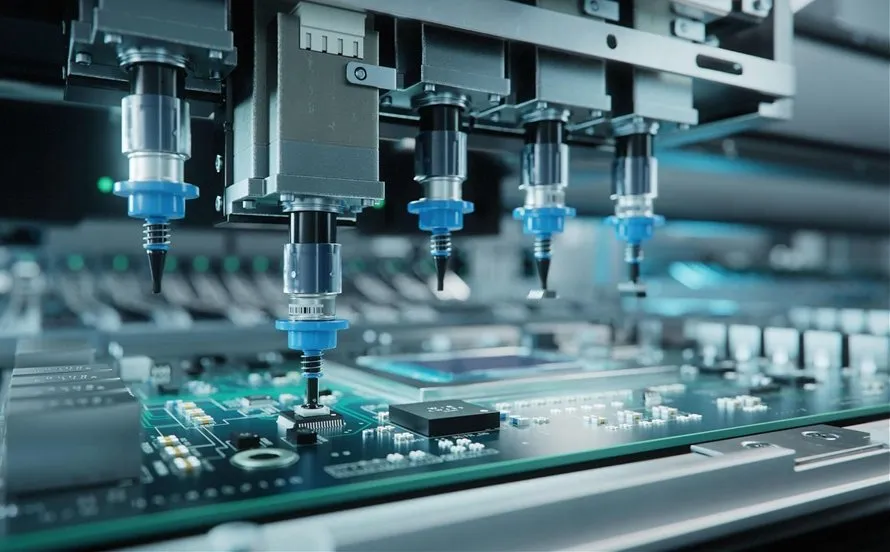

Look for a partner with advanced equipment, such as high-speed surface-mount technology (SMT) lines capable of placing components with pitches as fine as 0.3mm. Their facilities should also include automated optical inspection (AOI) systems to detect defects and X-ray machines for inspecting hidden solder joints in ball grid array (BGA) components. A manufacturer that can produce boards with up to 20 layers or more demonstrates the technical expertise needed for demanding projects.

Additionally, check if they support specialized materials like high-frequency laminates (with dielectric constants as low as 2.2 for RF applications) or high-Tg materials (glass transition temperatures above 170°C) for thermal stability. These capabilities ensure your multi-layer PCBs perform reliably under challenging conditions.

2. Evaluate Experience in Quality PCB Assembly

Quality PCB assembly is non-negotiable when it comes to multi-layer boards. Errors in soldering, component placement, or via drilling can compromise the entire board’s functionality, especially in applications requiring high-speed data transfer (up to 10 Gbps or higher).

Choose a partner with a proven track record in assembling complex multi-layer designs. They should have experience handling fine-pitch components (down to 0.4mm spacing) and mixed technologies, such as combining SMT with through-hole (THT) components. A reliable partner will also offer functional testing to verify that the assembled board meets your specifications before shipment.

Look for detailed case studies or testimonials showcasing their ability to deliver defect-free boards for industries like telecommunications, automotive, or medical, where reliability is critical. A partner with a defect rate below 1% (measured by defective parts per million, or DPM) indicates a strong commitment to quality.

3. Verify Relevant PCB Certifications

PCB certifications are a clear indicator of a manufacturer’s adherence to industry standards and quality control. Certifications demonstrate that the partner follows strict guidelines for design, manufacturing, and assembly processes, ensuring consistent results for your multi-layer PCBs.

Some key certifications to look for include:

- ISO 9001: Confirms a robust quality management system for consistent production.

- IPC-A-610: Sets standards for acceptable electronic assembly workmanship, critical for multi-layer boards.

- RoHS Compliance: Ensures the use of environmentally safe materials, avoiding hazardous substances.

- IATF 16949: Specific to automotive applications, guaranteeing high reliability for safety-critical systems.

- AS9100: Relevant for aerospace and defense, focusing on stringent quality and safety requirements.

A partner with these certifications is more likely to deliver boards that meet your performance and regulatory needs, especially for specialized industries.

4. Explore the Range of PCB Assembly Services

A comprehensive suite of PCB assembly services can simplify your project by reducing the need to coordinate with multiple vendors. Opt for a partner that offers end-to-end solutions, covering every stage from design to delivery.

Key services to look for include:

- Component Sourcing: The ability to procure high-quality components, including hard-to-find or obsolete parts, saves you time and ensures compatibility.

- Prototype Assembly: Quick-turn prototyping (within 24-48 hours for small batches) allows you to test designs before full production.

- Volume Production: Scalability to handle mid-to-high volume runs without compromising quality.

- Testing and Inspection: In-depth testing, such as in-circuit testing (ICT) and burn-in testing, to validate performance under real-world conditions.

- Box Build Assembly: Complete integration of PCBs into enclosures or final products, streamlining the final assembly process.

A partner offering these services under one roof minimizes communication gaps and accelerates your time-to-market, especially for complex multi-layer PCB projects.

5. Check Lead Times and Scalability

Lead times can make or break your project timeline. Multi-layer PCB production often takes longer due to intricate layer alignment and testing processes (standard lead times range from 2-4 weeks for small runs). A reliable PCB manufacturer should provide clear timelines and have the capacity to meet tight deadlines without sacrificing quality.

Scalability is equally important. Ensure the partner can transition seamlessly from prototype to mass production, handling order volumes that grow from a few units to thousands. Their supply chain should be robust enough to avoid delays due to component shortages, even during peak demand periods.

6. Review Quality Control Processes

Quality control (QC) is the cornerstone of quality PCB assembly. A dependable partner will have a well-documented QC process with multiple inspection points throughout manufacturing and assembly. This includes:

- Incoming Material Inspection: Verifying the quality of raw materials and components before use.

- In-Process Inspection: Monitoring each stage of assembly to catch issues early.

- Final Testing: Conducting electrical and functional tests to ensure the board performs as designed.

Traceability systems are also vital, allowing you to track every step of production and identify the source of any defects. A defect tracking system with a low failure rate (e.g., under 0.5% returns) reflects a strong QC framework.

7. Consider Technical Support and Communication

Effective communication with your PCB assembly partner can prevent misunderstandings and costly errors. Choose a manufacturer that provides dedicated technical support, ideally with engineers who can assist with design for manufacturability (DFM) reviews. A thorough DFM analysis can identify potential issues, such as improper trace widths (e.g., below 0.1mm for high-current paths), before production begins.

Ensure the partner offers clear communication channels, whether through email, phone, or a project management portal. Timely updates on production status and quick responses to concerns are signs of a reliable collaborator.

How to Shortlist Potential PCB Assembly Partners

With so many options available, narrowing down your choices can feel overwhelming. Follow these practical steps to create a shortlist of potential partners for PCB assembly services.

- Define Your Project Requirements: Outline your multi-layer PCB specifications, including layer count (e.g., 8 layers), board dimensions, and performance needs (e.g., signal speeds up to 5 Gbps).

- Research Online: Use industry forums, directories, and reviews to identify manufacturers with strong reputations for multi-layer boards.

- Request Quotes: Contact multiple vendors for detailed quotes, comparing pricing, lead times, and included services.

- Evaluate Past Work: Request samples or case studies of similar multi-layer PCB projects to assess their expertise.

- Visit Facilities (If Possible): A facility tour can provide insight into their equipment, processes, and commitment to quality.

By systematically evaluating each candidate based on the factors above, you’ll find a PCB manufacturer that aligns with your technical and business goals.

Red Flags to Watch Out For

Not all partners are created equal, and some warning signs can indicate potential issues. Be cautious of:

- Lack of Certifications: Absence of key PCB certifications like ISO 9001 or IPC standards may signal inconsistent quality.

- Vague Timelines: Unclear or overly optimistic delivery estimates can lead to delays.

- Poor Communication: Slow responses or lack of technical expertise during initial discussions are concerning.

- Limited Capabilities: If a manufacturer struggles with complex multi-layer designs or lacks advanced testing equipment, they may not meet your needs.

Steering clear of these red flags will help you avoid costly mistakes and ensure a smooth partnership.

The Benefits of Partnering with a Trusted PCB Manufacturer

Collaborating with a reliable PCB manufacturer offers numerous advantages for your multi-layer PCB projects:

- Reduced Risk: High quality PCB assembly minimizes defects and ensures boards function as intended.

- Faster Time-to-Market: Streamlined PCB assembly services and quick-turn capabilities accelerate product launches.

- Cost Efficiency: Avoiding rework and delays saves money in the long run, even if upfront costs are higher.

- Technical Expertise: Access to experienced engineers and advanced PCB manufacturing capabilities enhances design outcomes.

A trusted partner becomes an extension of your team, supporting innovation and ensuring your products meet the highest standards.

Conclusion: Make an Informed Choice for Multi-Layer PCB Success

Selecting a reliable multi-layer PCB assembly partner is a critical decision that impacts the quality, timeline, and success of your electronic projects. By focusing on PCB manufacturing capabilities, commitment to quality PCB assembly, relevant PCB certifications, and comprehensive PCB assembly services, you can find a PCB manufacturer that meets your needs.

Take the time to evaluate potential partners based on their technical expertise, quality control processes, and ability to scale with your project. A well-chosen partner will deliver high-performance multi-layer PCBs that power your innovations, from prototype to production.

At ALLPCB, we’re committed to providing top-tier solutions for multi-layer PCB assembly. With advanced technology, strict quality standards, and end-to-end services, we’re here to support your next project with precision and reliability.

ALLPCB

ALLPCB