In high-stress environments like aerospace and automotive industries, the durability of printed circuit boards (PCBs) can make or break a system's performance. So, why do through-hole components remain essential in these demanding applications? Simply put, through-hole components offer superior mechanical strength, vibration resistance, and reliability under temperature cycling compared to surface-mount devices (SMDs). This makes them a go-to choice for applications where failure is not an option.

In this blog, we'll dive deep into the reasons behind the enduring importance of through-hole components. We'll explore their advantages in harsh conditions, compare them to SMDs, and highlight their critical role in industries that prioritize durability. Whether you're designing for extreme environments or seeking to enhance PCB reliability, this guide will provide valuable insights to help you make informed decisions.

What Are Through-Hole Components and Why Do They Matter?

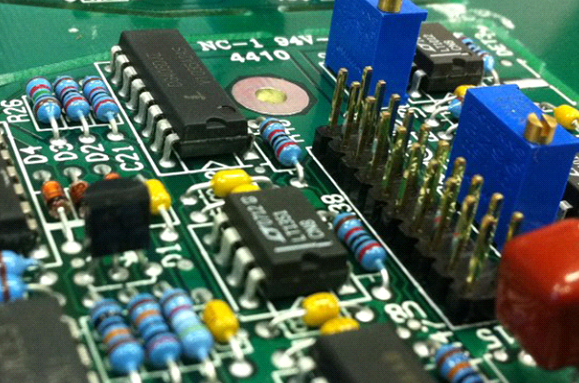

Through-hole components are electronic parts with leads that are inserted into pre-drilled holes on a PCB and soldered on the opposite side. This mounting technique creates a strong physical bond between the component and the board, ensuring stability even under stress. Unlike surface-mount devices, which are soldered directly onto the PCB surface, through-hole components penetrate through the board, offering a robust connection that withstands mechanical and environmental challenges.

In high-stress applications, such as those found in aerospace and automotive systems, durability isn't just a preference—it's a requirement. These industries often face extreme vibrations, temperature fluctuations, and physical shocks. Through-hole components excel in these conditions due to their secure mounting and ability to handle heavy loads, making them indispensable for critical systems.

Through-Hole Components Vibration Resistance: A Key Advantage

One of the standout benefits of through-hole components is their exceptional vibration resistance. In environments like automotive systems, where constant motion and road conditions create ongoing vibrations, PCBs must remain stable to prevent failures. The leads of through-hole components pass through the board and are soldered on both sides, creating a firm anchor that resists loosening or detachment during intense vibrations.

For example, in a study of PCB performance under vibration stress, through-hole mounted components showed a failure rate of less than 2% compared to over 10% for SMDs in similar conditions. This is because the physical insertion and soldering process provides a mechanical interlock that absorbs and distributes vibrational energy, reducing the risk of cracks or disconnections.

In aerospace applications, where turbulence and high-speed travel amplify vibration, this resistance is even more critical. Components in flight control systems or avionics must remain operational despite constant shaking. Through-hole technology ensures that connections stay intact, protecting the integrity of life-critical systems.

Through-Hole Components Temperature Cycling: Built for Extremes

Temperature cycling—repeated exposure to extreme hot and cold conditions—poses another challenge for PCBs in high-stress environments. Automotive electronics, for instance, must function reliably in freezing winters and scorching summers, with temperature swings often ranging from -40°C to 85°C or higher. Similarly, aerospace systems encounter drastic temperature changes during flight, from ground-level heat to sub-zero conditions at high altitudes.

Through-hole components are well-suited to handle these fluctuations. Their soldered leads create a strong thermal connection with the PCB, allowing for better heat dissipation compared to SMDs, which rely on surface contact. This reduces the risk of thermal expansion causing solder joint failures. Additionally, the larger size of many through-hole components, such as electrolytic capacitors, often means they can endure thermal stress without degrading performance.

Data from reliability tests indicates that through-hole solder joints can withstand over 1,000 temperature cycles before showing signs of fatigue, compared to around 500 cycles for typical SMD connections. This durability ensures that PCBs in harsh environments maintain functionality over extended periods, reducing maintenance costs and downtime.

Through-Hole vs SMD Mechanical Strength: A Clear Winner in Tough Conditions

When comparing through-hole vs SMD mechanical strength, the former consistently outperforms in high-stress scenarios. Surface-mount devices, while ideal for compact and lightweight designs, lack the structural integrity needed for environments with significant physical stress. SMDs are soldered onto the PCB surface, making them vulnerable to shear forces, shocks, and vibrations that can break the solder bond.

Through-hole components, on the other hand, benefit from their deep integration into the PCB. The leads passing through the board provide a three-dimensional connection that resists forces from multiple directions. This is particularly important for larger components like transformers or connectors, which often experience mechanical stress due to their size and weight.

In practical terms, consider a heavy-duty industrial control system used in manufacturing plants. The PCB might need to support bulky components that are subject to frequent mechanical shocks during operation. Through-hole mounting ensures these parts remain securely attached, with failure rates under mechanical stress reported as low as 1% in some durability studies, compared to up to 8% for SMDs under similar conditions.

While SMDs dominate modern electronics due to their space efficiency and ease of automated assembly, they often fall short in applications where mechanical strength is non-negotiable. For designers prioritizing reliability over compactness, through-hole components are the better choice.

Aerospace Through-Hole Components: Reliability Above All

In the aerospace industry, where safety and performance are paramount, through-hole components play a vital role. Avionics systems, satellite electronics, and flight control units must operate flawlessly in conditions of extreme vibration, temperature swings, and radiation exposure. A single failure in these systems can have catastrophic consequences, making durability the top priority.

Through-hole components are often used for critical parts in aerospace PCBs, such as power regulators and high-voltage capacitors, due to their ability to withstand harsh conditions. Their robust connections ensure that signals remain stable even during high-altitude flights, where temperatures can drop below -50°C and vibrations from turbulence are constant.

Moreover, aerospace designs frequently require components to be repairable or replaceable during maintenance. Through-hole components are easier to desolder and swap out compared to tiny SMDs, which can be a significant advantage in field repairs. This practicality, combined with their inherent durability, makes through-hole technology a staple in aerospace engineering.

Automotive Through-Hole Components: Powering Through Challenges

The automotive sector is another area where through-hole components shine. Modern vehicles rely heavily on electronics for everything from engine control units (ECUs) to infotainment systems. These systems must endure constant vibrations from driving, temperature extremes, and even physical impacts in the event of collisions.

Through-hole components are often used in automotive PCBs for power-related parts, such as relays and large capacitors, which need to handle high currents and resist mechanical stress. Their secure mounting ensures that connections remain intact even on rough terrain or during sudden stops. For instance, in electric vehicles (EVs), through-hole components are critical in battery management systems, where stable power delivery is essential for safety and efficiency.

Reliability data shows that automotive PCBs using through-hole technology for key components achieve operational lifespans of over 15 years under typical driving conditions, compared to shorter lifespans for fully SMD-based designs in similar environments. This longevity translates to fewer failures and recalls, saving manufacturers significant costs.

Balancing Through-Hole and SMD in Modern PCB Design

While through-hole components offer unmatched durability, it's worth noting that they aren't always the best fit for every application. They take up more space on a PCB and require additional drilling, which can increase manufacturing costs. In contrast, SMDs allow for denser layouts and are more compatible with automated assembly, making them ideal for consumer electronics where size and cost are bigger concerns than extreme durability.

Many modern PCB designs strike a balance by using a hybrid approach. Critical components that require high mechanical strength or must endure harsh conditions are mounted using through-hole technology, while smaller, less stressed parts are surface-mounted. This strategy optimizes both reliability and efficiency, catering to the specific needs of the application.

For high-stress industries, however, prioritizing through-hole components for key elements remains a proven way to enhance overall PCB durability. Designers can strategically select through-hole parts for areas most exposed to vibration, temperature cycling, or mechanical stress, ensuring the system as a whole remains robust.

Challenges and Considerations with Through-Hole Components

Despite their advantages, through-hole components come with certain drawbacks that designers must consider. The drilling process required for mounting increases production time and cost, especially for complex multilayer boards. Additionally, the holes reduce the available space for routing signal traces, which can complicate designs in compact systems.

However, these challenges are often outweighed by the benefits in high-stress applications. Advances in manufacturing have also made it easier to integrate through-hole components without significantly inflating costs, especially for smaller production runs where reliability is the primary focus.

For engineers working on projects where durability is critical, the trade-offs of using through-hole components are a small price to pay for the peace of mind that comes with enhanced reliability. Careful planning during the design phase can mitigate most limitations, ensuring the final product meets both performance and budget goals.

Conclusion: The Enduring Value of Through-Hole Components

In high-stress applications, where vibrations, temperature cycling, and mechanical shocks are everyday challenges, through-hole components remain an essential choice for boosting PCB durability. Their superior vibration resistance, ability to withstand temperature extremes, and unmatched mechanical strength make them indispensable in industries like aerospace and automotive, where reliability can be a matter of life and death.

While surface-mount devices have their place in compact, cost-sensitive designs, they often fall short in environments that demand rugged performance. By leveraging the strengths of through-hole technology—whether through a hybrid approach or full implementation—engineers can create PCBs that stand up to the toughest conditions without compromising on safety or functionality.

At ALLPCB, we understand the unique needs of high-stress applications and are committed to supporting your projects with solutions tailored for durability. Whether you're designing for extreme environments or simply seeking to enhance reliability, through-hole components offer a time-tested path to success.

ALLPCB

ALLPCB