In the world of electronics manufacturing, automating through-hole assembly has become a game-changer for improving efficiency, precision, and reliability in PCB production. If you're looking to understand how technologies like through-hole component insertion machines, wave soldering automation, selective soldering equipment, automated optical inspection for through-hole, and robotic through-hole assembly can transform your manufacturing process, you're in the right place. This blog dives deep into these cutting-edge solutions, offering practical insights and detailed explanations to help you stay ahead in the industry.

At its core, through-hole assembly involves mounting electronic components by inserting their leads through pre-drilled holes on a printed circuit board (PCB) and soldering them in place. While surface mount technology (SMT) has gained popularity, through-hole technology (THT) remains essential for applications requiring high durability and reliability, such as in automotive, aerospace, and industrial electronics. Automating this process reduces human error, speeds up production, and ensures consistent quality. Let's explore the technologies and equipment driving this automation revolution.

What Is Through-Hole Assembly and Why Automate?

Through-hole assembly is a traditional method of PCB manufacturing where components like resistors, capacitors, and connectors are placed on a board by inserting their leads through drilled holes. These leads are then soldered to pads on the opposite side, creating strong mechanical and electrical connections. Unlike SMT, which uses smaller components placed directly on the board's surface, THT is preferred for components that need to withstand high stress or heat.

Automating through-hole assembly offers several advantages. Manual insertion and soldering are time-consuming and prone to errors, especially in high-volume production. Automation ensures precision in component placement, consistent soldering quality, and faster turnaround times. It also reduces labor costs and minimizes defects, which can be critical in industries where reliability is non-negotiable. With advancements in technology, automated systems can now handle complex assemblies with ease, making them indispensable for modern manufacturing.

Key Technologies in Automating Through-Hole Assembly

The automation of through-hole assembly relies on several specialized technologies and equipment. Each plays a unique role in streamlining the process, from component insertion to final inspection. Below, we break down the most important systems driving this transformation.

1. Through-Hole Component Insertion Machines

Through-hole component insertion machines are at the heart of automating the placement of components on PCBs. These machines are designed to handle a wide range of components, from axial and radial types to more complex connectors. They use precise mechanisms to insert component leads into pre-drilled holes at high speeds, often achieving rates of thousands of components per hour.

Modern insertion machines are equipped with programmable settings to accommodate different board layouts and component sizes. Some advanced models feature vision systems to detect hole positions and ensure accurate placement, reducing the risk of misalignment. For example, high-end machines can achieve placement accuracy within 0.1 mm, which is crucial for dense PCB designs. By automating this step, manufacturers can significantly boost throughput while maintaining quality.

2. Wave Soldering Automation

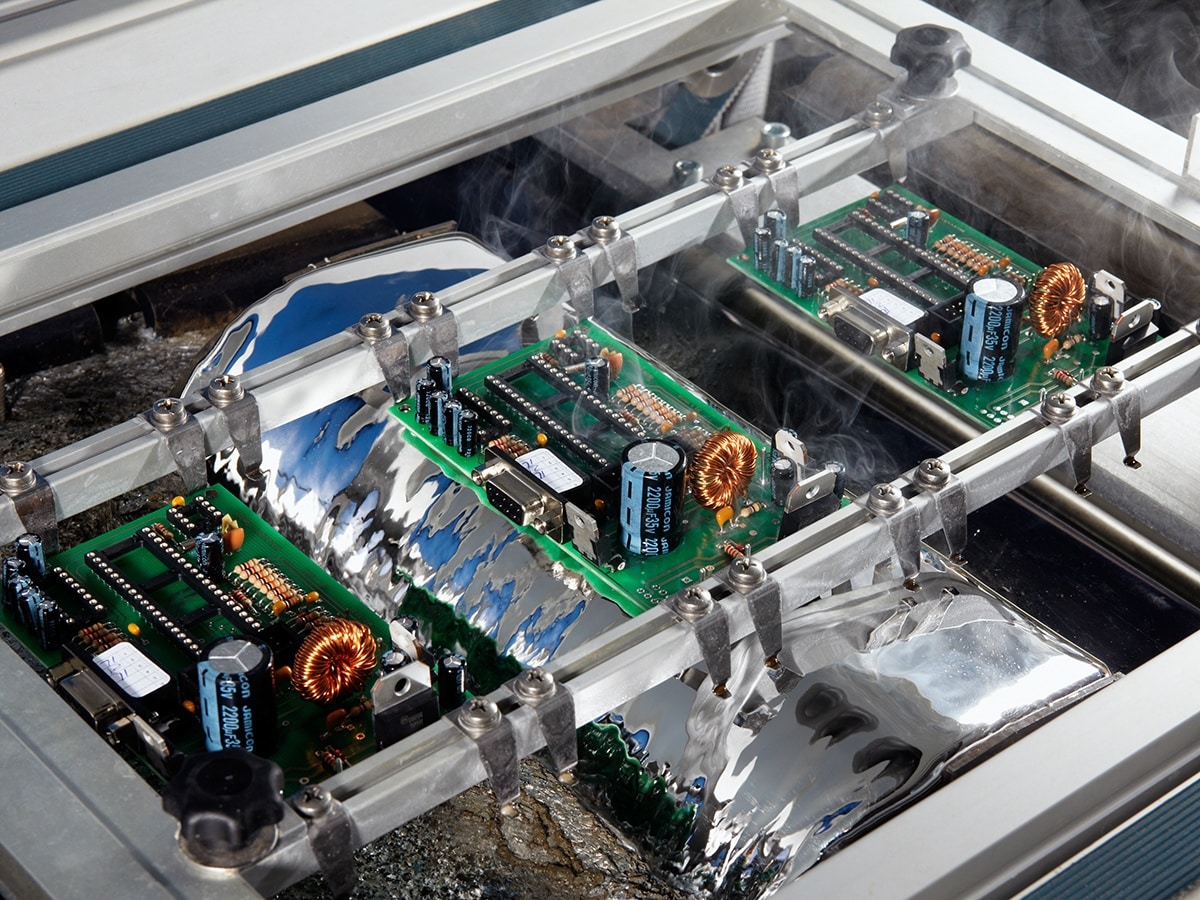

Wave soldering is a widely used technique for soldering through-hole components on PCBs. In this process, a PCB is passed over a wave of molten solder, which adheres to the exposed leads and pads, creating reliable connections. Automating wave soldering takes this process to the next level by integrating conveyor systems, precise temperature controls, and flux application mechanisms.

Automated wave soldering systems ensure uniform solder joints by maintaining consistent wave height and temperature, often within a range of 250-260°C for lead-free solder. They also minimize defects like solder bridges or insufficient wetting by using advanced fluxing techniques. For high-volume production, these systems can process hundreds of boards per hour, making them ideal for industries with large-scale needs.

3. Selective Soldering Equipment

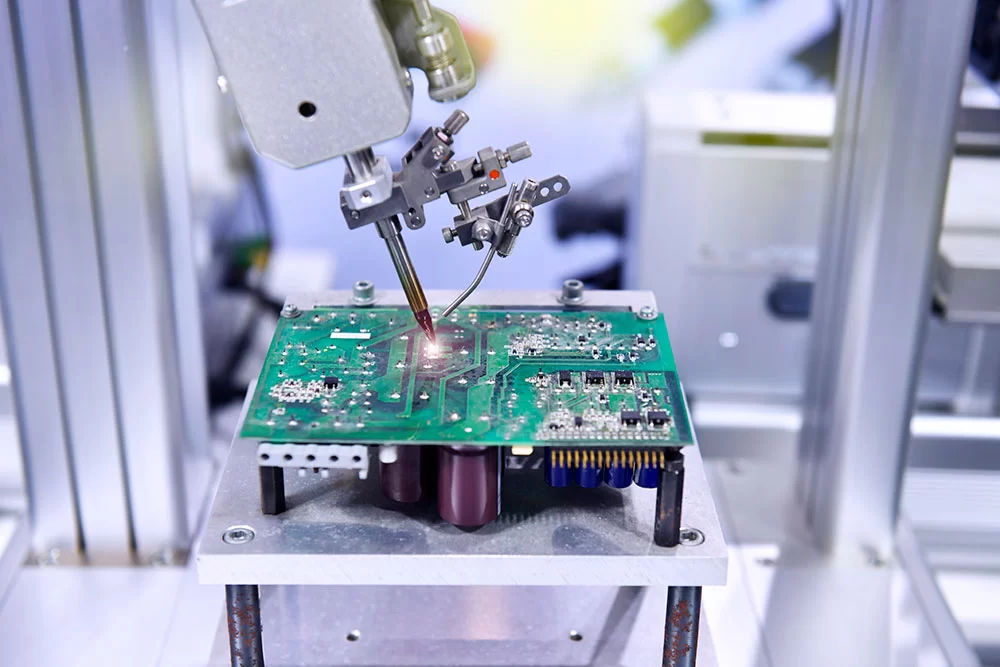

While wave soldering is effective for full-board soldering, selective soldering equipment is designed for precision. This technology targets specific areas of a PCB, soldering only the through-hole components without affecting nearby surface mount components or sensitive areas. It's particularly useful for mixed-technology boards where SMT and THT coexist.

Selective soldering systems use mini-wave or laser soldering heads to apply solder with pinpoint accuracy. They often include programmable nozzles and real-time monitoring to adjust soldering parameters, ensuring optimal results. For instance, a typical selective soldering machine can maintain a positional accuracy of ±0.05 mm, which is essential for intricate designs. This automation reduces thermal stress on the board and improves overall quality.

4. Automated Optical Inspection for Through-Hole

Quality control is a critical step in PCB assembly, and automated optical inspection (AOI) systems are indispensable for through-hole assemblies. AOI uses high-resolution cameras and advanced algorithms to inspect solder joints, component placement, and board integrity after assembly. For through-hole components, AOI can detect issues like insufficient solder, misaligned leads, or missing components with high accuracy.

Modern AOI systems can scan a PCB in under 10 seconds, even for complex designs with hundreds of components. They often use 3D imaging to assess solder joint shapes and detect defects that 2D systems might miss. By automating inspection, manufacturers can catch defects early, reducing rework costs and ensuring compliance with industry standards like IPC-A-610.

5. Robotic Through-Hole Assembly

Robotic through-hole assembly represents the future of automation in PCB manufacturing. These systems use robotic arms equipped with grippers or specialized tools to handle component insertion, soldering, and even board handling. Unlike traditional insertion machines, robotic systems offer greater flexibility, adapting to varying component shapes and board layouts without extensive reconfiguration.

Advanced robotic systems integrate machine vision and AI to optimize placement and soldering processes in real time. For example, some robots can adjust insertion force based on component resistance, preventing damage to delicate parts. They can also achieve speeds of up to 5 components per second, rivaling dedicated insertion machines while offering more versatility. This technology is ideal for low-to-medium volume production with frequent design changes.

Benefits of Automating Through-Hole Assembly

Automating through-hole assembly brings a host of benefits that can transform your manufacturing process. Let's look at some of the key advantages:

- Increased Efficiency: Automated systems can operate 24/7 with minimal downtime, significantly increasing production rates compared to manual assembly. For instance, a fully automated line can produce thousands of boards per day.

- Improved Quality: Precision equipment reduces human error, ensuring consistent component placement and soldering. This leads to fewer defects and higher reliability, critical for applications like medical devices.

- Cost Savings: While the initial investment in automation is significant, the reduction in labor costs and rework expenses offers long-term savings. Automation also lowers the cost per unit in high-volume production.

- Scalability: Automated systems can easily scale to meet growing demand, whether you're producing small batches or mass quantities.

- Safety: Automation minimizes human exposure to hazardous processes like soldering, improving workplace safety.

Challenges in Automating Through-Hole Assembly

Despite its many benefits, automating through-hole assembly comes with challenges that manufacturers must address. Understanding these hurdles can help you make informed decisions when adopting automation.

- High Initial Costs: Equipment like through-hole component insertion machines and selective soldering systems can be expensive, often costing tens of thousands of dollars. Small manufacturers may struggle with the upfront investment.

- Complexity in Setup: Configuring automated systems for specific PCB designs requires technical expertise and time. Frequent design changes can slow down production if reprogramming is needed.

- Limited Flexibility: Some automated systems are optimized for high-volume, repetitive tasks and may not adapt well to custom or low-volume projects without additional investment in versatile equipment like robotic systems.

- Maintenance Needs: Automated equipment requires regular maintenance to ensure optimal performance. Downtime for repairs can disrupt production if not managed properly.

Choosing the Right Automation Solution for Your Needs

Selecting the right technologies and equipment for automating through-hole assembly depends on several factors, including production volume, budget, and design complexity. Here are some tips to guide your decision:

- Assess Your Volume: For high-volume production, wave soldering automation and dedicated insertion machines offer the best efficiency. For smaller runs or mixed-technology boards, consider selective soldering equipment and robotic systems.

- Evaluate Component Types: Ensure the equipment you choose can handle the range of components in your designs, from standard resistors to complex connectors.

- Prioritize Quality Control: Investing in automated optical inspection for through-hole assemblies is essential, especially for industries with strict reliability standards.

- Plan for Growth: Choose scalable solutions that can accommodate future increases in production or changes in design requirements.

Future Trends in Through-Hole Assembly Automation

The field of through-hole assembly automation is evolving rapidly, driven by advancements in technology. Here are some trends to watch:

- Integration of AI and IoT: Future systems will use artificial intelligence to optimize processes in real time, while Internet of Things (IoT) connectivity will enable remote monitoring and predictive maintenance.

- Enhanced Robotics: Robotic through-hole assembly systems will become more affordable and versatile, making them accessible to smaller manufacturers.

- Green Manufacturing: Automation will focus on reducing waste and energy consumption, with systems designed for eco-friendly soldering materials and processes.

- Advanced Inspection: Automated optical inspection for through-hole will incorporate machine learning to detect even subtle defects, further improving quality control.

Conclusion

Automating through-hole assembly is a powerful way to enhance efficiency, quality, and scalability in PCB manufacturing. Technologies like through-hole component insertion machines, wave soldering automation, selective soldering equipment, automated optical inspection for through-hole, and robotic through-hole assembly are transforming the industry, offering solutions for a wide range of production needs. By understanding the benefits, challenges, and future trends of these systems, you can make informed decisions to optimize your manufacturing process.

Whether you're a small-scale operation or a large-volume producer, the right automation tools can help you achieve consistent results and stay competitive in a fast-paced market. Embracing these advancements ensures that your through-hole assemblies meet the highest standards of reliability and performance, no matter the application.

ALLPCB

ALLPCB