If you’re an electrical engineer working on medical devices, you’ve likely asked: What are the best biocompatible PCB materials for pacemakers? The short answer is that materials like polyimide, Rogers laminates, and certain ceramics are top choices due to their biocompatibility, high reliability, and ability to withstand the harsh environment of the human body. Selecting the right pacemaker PCB substrate is critical for ensuring long-term performance and patient safety. In this guide, we’ll dive deep into biocompatible PCB materials for pacemakers, explore pacemaker PCB substrate selection criteria, discuss Rogers materials for pacemaker PCBs, evaluate polyimide PCB for medical implants, and cover material certification for pacemaker PCBs. Let’s get started with everything you need to know to make informed decisions.

Why Material Selection Matters for Pacemaker PCBs

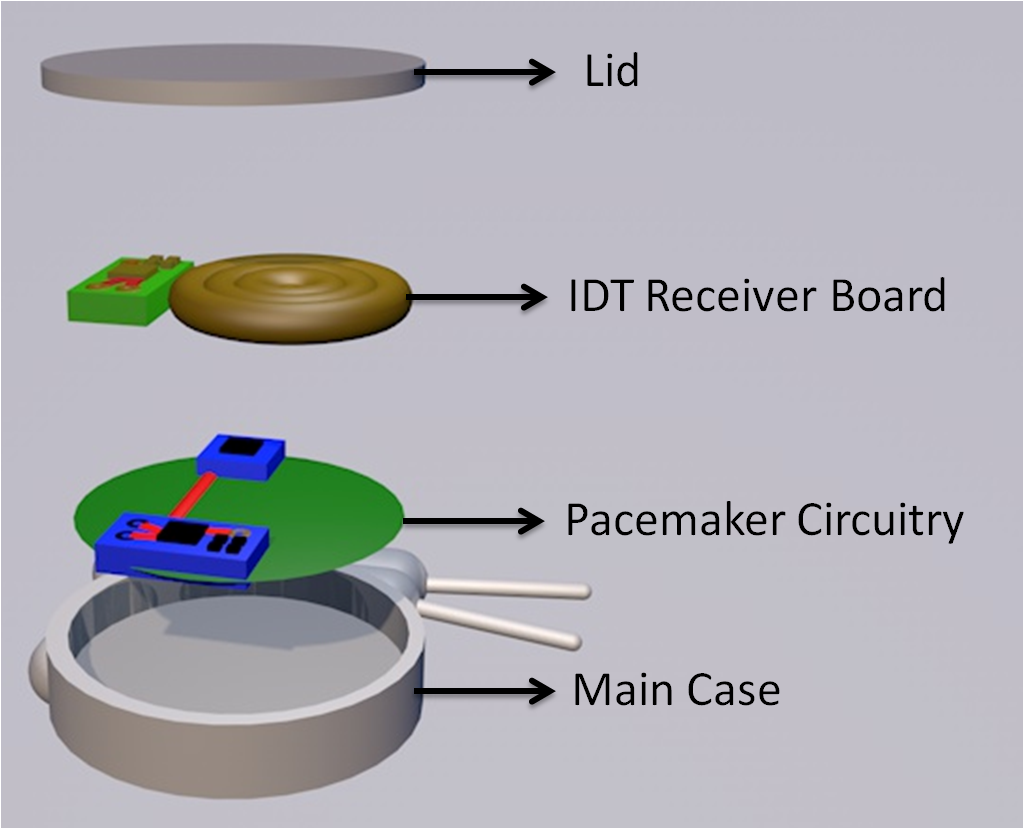

Designing printed circuit boards (PCBs) for pacemakers isn’t just about functionality—it’s about life and death. Pacemakers are implantable medical devices that regulate heartbeats, and their PCBs must operate flawlessly for years inside the human body. This means the materials used must be biocompatible (non-toxic to the body), durable under physiological conditions (like moisture and temperature fluctuations), and capable of maintaining electrical performance with minimal signal loss. A poor material choice could lead to device failure, immune reactions, or even patient harm.

As an engineer, your goal is to balance electrical performance with biocompatibility and reliability. For instance, a typical pacemaker PCB needs to handle low-power signals with impedances often in the range of 50-100 ohms while ensuring no degradation over time. Let’s break down the key considerations and materials that meet these stringent requirements.

Key Criteria for Pacemaker PCB Substrate Selection

When selecting a substrate for a pacemaker PCB, you’re not just picking a material—you’re ensuring the device’s long-term success. Here are the critical factors to consider during pacemaker PCB substrate selection:

- Biocompatibility: The material must not trigger immune responses or release toxic substances. It should comply with standards like ISO 10993, which tests for cytotoxicity and irritation.

- Electrical Performance: Low dielectric constant (Dk) and loss tangent (Df) are essential for minimizing signal loss, especially for high-frequency signals in modern pacemakers. For example, a Dk below 3.5 and Df below 0.005 are often ideal.

- Mechanical Stability: The substrate must resist cracking or delamination under stress. Pacemakers endure constant movement with each heartbeat, so flexibility and durability are key.

- Thermal Resistance: The material must handle body temperature (around 37°C) and potential localized heat from circuitry without degrading.

- Chemical Resistance: Exposure to bodily fluids like blood or saline can corrode materials. Substrates must resist moisture absorption and chemical breakdown.

- Miniaturization: Pacemakers are small, so the PCB substrate must support fine-line traces (often below 50 microns) for compact designs.

With these criteria in mind, let’s explore the top materials used in biocompatible PCB materials for pacemakers.

Top Biocompatible PCB Materials for Pacemakers

1. Polyimide PCB for Medical Implants

Polyimide is a go-to material for medical implant PCBs, including pacemakers, due to its flexibility and biocompatibility. Often used in flexible and rigid-flex PCBs, polyimide can bend without breaking, making it ideal for devices that conform to the body’s shape or endure constant motion.

- Key Benefits: Polyimide has a high thermal stability (up to 260°C), excellent chemical resistance, and a low dielectric constant (around 3.4), ensuring minimal signal interference.

- Applications: It’s widely used in pacemaker leads and interconnects where space is tight, and flexibility is needed.

- Challenges: Polyimide can be more expensive than traditional FR-4 materials, and its moisture absorption (around 1-3%) requires careful encapsulation to prevent long-term degradation.

For engineers, polyimide is a reliable choice when designing polyimide PCB for medical implants, especially when paired with proper hermetic sealing to protect against bodily fluids.

2. Rogers Materials for Pacemaker PCBs

Rogers Corporation offers high-performance laminates that are increasingly popular in medical device design, including Rogers materials for pacemaker PCBs. Materials like Rogers RO3000 and RO4000 series are known for their low dielectric loss and consistent performance at high frequencies.

- Key Benefits: Rogers materials typically have a dielectric constant between 3.0 and 3.5 and a loss tangent as low as 0.001, making them excellent for maintaining signal integrity in compact pacemaker circuits. They also offer good thermal stability and low moisture absorption (less than 0.1%).

- Applications: These materials are ideal for RF components in pacemakers, such as wireless communication modules for remote monitoring.

- Challenges: Cost is a significant barrier, as Rogers laminates are pricier than standard materials. Additionally, their rigidity may limit use in flexible designs.

For high-frequency applications in pacemakers, Rogers materials are often the best choice, though you’ll need to weigh cost against performance needs.

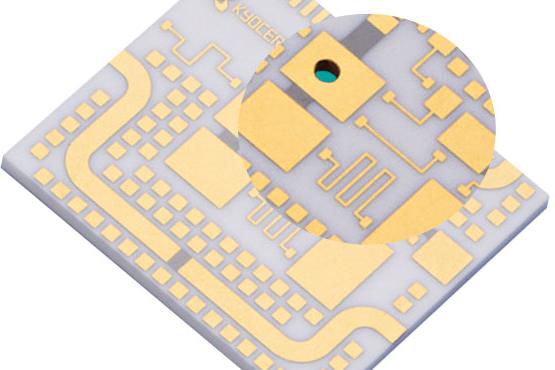

3. Ceramic Substrates for High-Reliability

Ceramic substrates, such as alumina (Al2O3) and aluminum nitride (AlN), are used in pacemakers for their exceptional reliability and biocompatibility. These materials are often chosen for hybrid circuits or when extreme durability is required.

- Key Benefits: Ceramics offer excellent thermal conductivity (up to 30 W/mK for AlN), high mechanical strength, and near-zero moisture absorption. Their dielectric constant can range from 8 to 10, suitable for specific high-density designs.

- Applications: Used in power management circuits within pacemakers where heat dissipation is critical.

- Challenges: Ceramics are brittle and expensive to process, often requiring specialized manufacturing techniques.

Ceramics are a niche but powerful option for engineers prioritizing reliability over flexibility in biocompatible PCB materials for pacemakers.

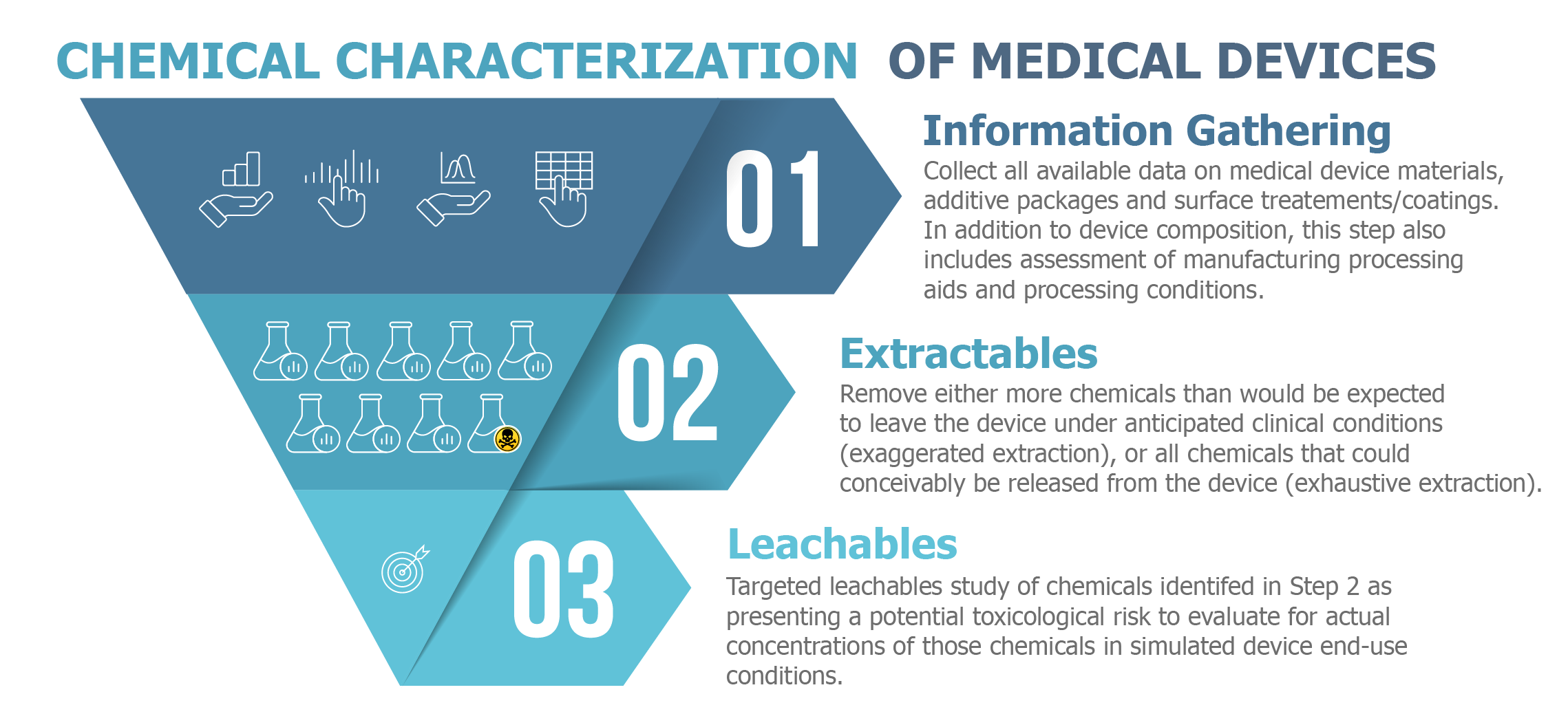

Material Certification for Pacemaker PCBs: Ensuring Compliance

One of the most critical aspects of designing pacemaker PCBs is ensuring that materials meet regulatory standards. Material certification for pacemaker PCBs isn’t just a checkbox—it’s a guarantee of patient safety. Here are the key certifications and standards to focus on:

- ISO 10993: This standard evaluates biocompatibility through tests for cytotoxicity, sensitization, and irritation. All materials in contact with the body, directly or indirectly, must pass these tests.

- FDA Guidelines: In the U.S., the Food and Drug Administration requires detailed documentation on material safety and performance for Class III devices like pacemakers.

- RoHS Compliance: While not directly related to biocompatibility, Restriction of Hazardous Substances (RoHS) compliance ensures that harmful substances like lead are absent from the PCB.

- IPC Standards: Standards like IPC-6013 for flexible PCBs ensure manufacturing quality and reliability, which are critical for medical applications.

As an engineer, always request material datasheets and certification reports from suppliers. For instance, when using polyimide or Rogers materials, confirm that they’ve been tested under ISO 10993 protocols. Partnering with manufacturers who specialize in medical-grade materials can save time and reduce risks.

Comparing Material Options: Which Is Best for Your Design?

Choosing between polyimide, Rogers materials, and ceramics depends on your specific design needs. Here’s a quick comparison to guide your pacemaker PCB substrate selection:

| Material | Biocompatibility | Flexibility | Dielectric Constant (Dk) | Cost | Best Use Case |

|---|---|---|---|---|---|

| Polyimide | High (with proper coating) | Excellent | ~3.4 | Moderate to High | Flexible circuits, leads |

| Rogers Laminates | High (certified grades) | Low (rigid) | 3.0-3.5 | High | High-frequency, RF modules |

| Ceramics | Very High | None (brittle) | 8-10 | Very High | Power management, hybrid circuits |

This table can help you narrow down options based on electrical requirements, mechanical constraints, and budget. For instance, if your pacemaker design prioritizes wireless communication, Rogers materials might be worth the investment for their low signal loss.

Practical Tips for Engineers Designing Pacemaker PCBs

Here are some actionable tips based on industry practices to help you succeed in designing pacemaker PCBs:

- Test Early and Often: Prototype your PCB with candidate materials and test them under simulated body conditions (e.g., saline solutions at 37°C) to identify potential failures.

- Collaborate with Material Suppliers: Companies like Rogers Corporation or DuPont (for polyimide) often provide technical support and medical-grade material options tailored for implants.

- Prioritize Encapsulation: Even biocompatible materials can degrade over time. Use hermetic sealing or parylene coatings to protect against moisture and ions in the body.

- Stay Updated on Standards: Regulatory requirements evolve. Keep an eye on updates to ISO 10993 or FDA guidelines to ensure compliance during material certification for pacemaker PCBs.

- Balance Cost and Performance: While high-end materials like Rogers laminates offer superior performance, consider hybrid designs (e.g., combining polyimide and FR-4) for non-critical areas to reduce costs.

Real-World Challenges in Pacemaker PCB Design

Let’s talk about real challenges engineers face. I recall a project where a team struggled with signal degradation in a pacemaker PCB after long-term exposure to bodily fluids. The initial substrate, a standard FR-4, absorbed moisture (over 2% by weight) and caused impedance mismatches, leading to unreliable pacing signals. Switching to a polyimide-based flex PCB with a parylene coating solved the issue, but it came at a higher cost and required redesigning parts of the circuit layout. This example underscores why early material testing and selecting biocompatible PCB materials for pacemakers are non-negotiable.

Another challenge is miniaturization. Modern pacemakers are shrinking, with some designs under 2 cm3. This pushes engineers to use materials that support ultra-fine traces (below 25 microns) while maintaining reliability. Polyimide and Rogers materials often shine here, but they require advanced fabrication techniques, which can strain budgets and timelines.

Future Trends in Pacemaker PCB Materials

The field of medical device design is evolving rapidly. Emerging materials like bioresorbable polymers and advanced composites are being researched for temporary implants, though they’re not yet common in pacemakers. Additionally, flexible hybrid electronics (combining rigid and flex materials) are gaining traction for their ability to integrate more functionality into smaller spaces.

Another trend is the push for sustainable materials. While not a primary concern for pacemakers, some manufacturers are exploring eco-friendly substrates that still meet biocompatibility standards. Staying ahead of these trends can give your designs a competitive edge.

Conclusion: Making the Right Choice for Pacemaker PCB Substrates

Selecting the right material for a pacemaker PCB is a complex but critical task. Whether you choose a polyimide PCB for medical implants for its flexibility, Rogers materials for pacemaker PCBs for high-frequency performance, or ceramics for unmatched reliability, your decision must prioritize biocompatibility, electrical performance, and regulatory compliance. By understanding the nuances of pacemaker PCB substrate selection and ensuring material certification for pacemaker PCBs, you can design devices that save lives with confidence.

As an electrical engineer, remember that every material choice is a trade-off between cost, performance, and manufacturability. Use the insights and tips in this guide to navigate those trade-offs and create pacemakers that stand the test of time—both in the lab and in the human body.

ALLPCB

ALLPCB