Designing a printed circuit board (PCB) for a prosthetic device requires careful selection of components to ensure reliability, safety, and performance. When choosing components for your prosthetic device PCB, prioritize factors like biocompatibility, power efficiency, durability, and compliance with medical standards. This blog dives deep into the process of selecting electronic components for prosthetics, offering practical tips on component sourcing for medical PCBs and ensuring your design meets the unique demands of medical applications.

Why Component Selection Matters for Prosthetic Device PCBs

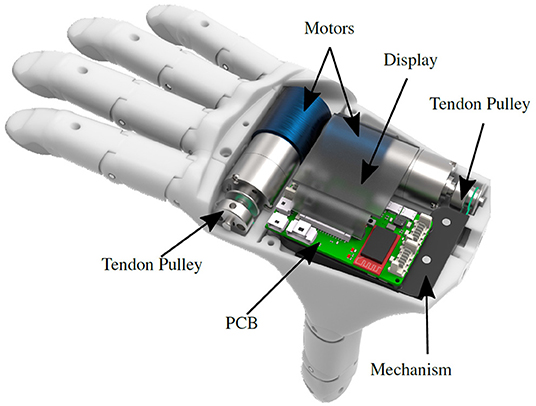

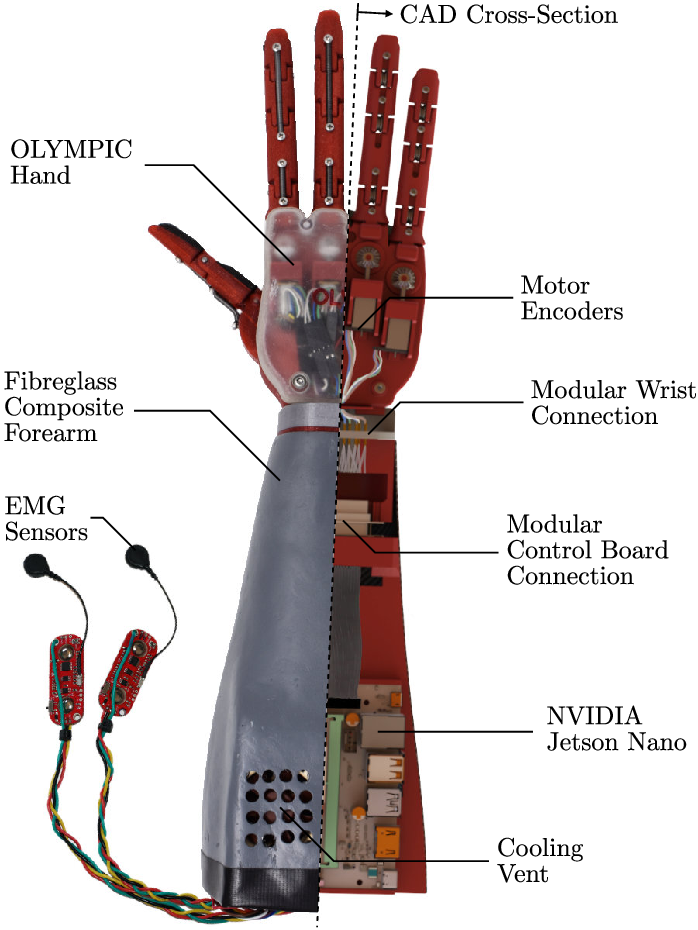

Prosthetic devices are life-changing tools that help individuals regain mobility and independence. The PCB inside these devices acts as the central nervous system, controlling motors, sensors, and communication systems. A single poorly chosen component can lead to device failure, safety risks, or discomfort for the user. Therefore, selecting the right components for your prosthetic device PCB is not just a technical decision—it’s a matter of ensuring functionality and trust.

In this guide, we’ll walk through the key considerations for choosing components, from understanding the specific needs of prosthetics to navigating medical-grade standards. Whether you’re an engineer or a designer, this blog will help you make informed decisions for your next project.

Understanding the Unique Needs of Prosthetic Device PCBs

Before diving into component selection, it’s important to understand the unique challenges of designing PCBs for prosthetics. These devices often operate in demanding conditions, requiring components that can handle:

- Compact Size: Prosthetics need lightweight and small PCBs to fit within limited space without adding bulk.

- Power Efficiency: Battery life is critical, as users rely on prosthetics for extended periods. Components must minimize power consumption.

- Durability: Components must withstand physical stress, vibrations, and environmental factors like moisture or temperature changes.

- Biocompatibility: Materials and components near the skin must avoid causing irritation or allergic reactions.

- Safety and Reliability: Failure is not an option in medical devices. Components must meet strict standards to ensure consistent performance.

Keeping these needs in mind, let’s explore the step-by-step process of selecting electronic components for prosthetics.

Step 1: Define the Functional Requirements of Your Prosthetic Device

Start by outlining the specific functions your prosthetic device PCB must support. For example:

- Will it control a motorized joint with precise movements? You’ll need microcontrollers (MCUs) with high processing power and motor drivers capable of handling specific current and voltage levels, such as 12V to 24V for small motors.

- Does it include sensors for pressure or touch feedback? Look for sensors with low noise levels and high sensitivity, like capacitive touch sensors with a signal-to-noise ratio (SNR) of at least 50:1.

- Is wireless communication required for data transfer or remote control? Choose low-power Bluetooth modules with a range of at least 10 meters and data rates supporting real-time updates (e.g., 1 Mbps).

By defining these requirements, you create a clear roadmap for component selection. This step ensures you don’t waste time or resources on parts that don’t meet your project’s needs.

Step 2: Prioritize Power Efficiency and Battery Life

Power efficiency is a top priority for prosthetic devices, as users often depend on battery-powered systems for daily use. Selecting components with low power consumption can extend battery life significantly. Here’s how to approach this:

- Microcontrollers (MCUs): Opt for low-power MCUs with sleep modes that reduce current draw to microampere levels (e.g., less than 10 μA in deep sleep). Look for chips with operating voltages as low as 1.8V to 3.3V.

- Regulators: Use efficient voltage regulators with low quiescent current (e.g., under 50 μA) to minimize power loss during conversion.

- Sensors and Modules: Choose sensors and communication modules with power-saving features, such as duty-cycling, where the component only activates when needed.

For instance, a prosthetic arm might use a lithium-ion battery with a capacity of 2000 mAh. If components draw excessive power, the battery could drain in hours. By selecting energy-efficient parts, you can extend usage to a full day or more, improving user experience.

Step 3: Ensure Durability and Environmental Resistance

Prosthetic devices face physical stress and varying environmental conditions. Components on the PCB must be robust enough to handle these challenges. Consider the following:

- Temperature Range: Select components rated for a wide temperature range, such as -40°C to 85°C, to ensure functionality in hot or cold environments.

- Moisture Resistance: Look for components with conformal coatings or IP ratings (e.g., IP65 or higher) to protect against sweat or humidity.

- Shock and Vibration Tolerance: Choose parts with high mechanical stability, such as surface-mount devices (SMDs) with secure soldering points, to prevent failure during movement.

For example, a prosthetic leg used during outdoor activities might encounter rain or dust. Using components with proper environmental protection ensures the PCB remains functional over time.

Step 4: Focus on Biocompatibility and Safety Standards

Since prosthetic devices often come into close contact with the human body, biocompatibility is a critical factor in component selection. Components and materials must not cause skin irritation or toxic reactions. Additionally, they must comply with medical safety standards like ISO 13485 and IEC 60601-1, which govern medical device manufacturing.

- Material Safety: Avoid components with harmful substances like lead or certain plastics. Opt for RoHS-compliant parts to ensure safety.

- Electromagnetic Compatibility (EMC): Ensure components minimize electromagnetic interference (EMI) to avoid disrupting other medical devices or causing harm. Look for parts with shielding or low EMI emissions.

- Certification: Source components from suppliers who provide documentation proving compliance with medical-grade standards.

By adhering to these standards, you reduce the risk of regulatory issues and ensure the device is safe for end users.

Step 5: Source Components from Reliable Suppliers

Component sourcing for medical PCBs is a critical step that can impact the quality and timeline of your project. Working with trusted suppliers ensures you get authentic, high-quality parts that meet your specifications. Here are some tips for effective sourcing:

- Verify Supplier Credentials: Choose suppliers with experience in medical device components and a track record of providing certified parts.

- Check Availability: Ensure the supplier can provide consistent stock levels to avoid delays, especially for long-term production.

- Request Samples: Test components before committing to bulk orders to confirm they meet your performance and safety requirements.

- Traceability: Opt for suppliers who offer full traceability of components, so you can track the origin and batch of each part for quality assurance.

Building strong relationships with suppliers can also help you access technical support and expedite orders when needed, streamlining the development process for your prosthetic device PCB.

Step 6: Test and Validate Your Component Choices

Once you’ve selected components, rigorous testing is essential to validate their performance in real-world conditions. This step helps identify potential issues before the device reaches the user. Consider these testing methods:

- Simulation: Use software tools to simulate the PCB design and analyze how components behave under different loads and conditions.

- Prototyping: Build a prototype PCB and test it in scenarios mimicking actual use, such as repetitive motion for a prosthetic arm.

- Stress Testing: Subject components to extreme conditions (e.g., high humidity or temperature) to ensure they hold up over time.

- User Feedback: If possible, involve end users in testing to gather insights on comfort and functionality.

For example, if a sensor in a prosthetic foot fails to detect pressure accurately during testing, you can replace it with a more reliable alternative before final production. This proactive approach saves time and resources in the long run.

Common Challenges in Selecting Components for Prosthetic PCBs

Even with careful planning, engineers often face challenges when selecting electronic components for prosthetics. Being aware of these issues can help you avoid pitfalls:

- Cost vs. Quality: High-quality medical-grade components can be expensive. Balance cost with performance by prioritizing critical components (like MCUs and sensors) for higher budgets.

- Supply Chain Delays: Global shortages or shipping issues can delay projects. Plan ahead by ordering components early and maintaining backup suppliers.

- Compatibility Issues: Ensure all components work seamlessly together. For instance, a microcontroller operating at 3.3V won’t pair well with a sensor requiring 5V without proper level shifting.

Addressing these challenges upfront minimizes disruptions and keeps your project on track.

Future Trends in Prosthetic Device PCB Components

The field of prosthetics is evolving rapidly, and staying ahead of trends can give your designs a competitive edge. Here are some emerging developments in prosthetic device PCB components:

- Miniaturization: Advances in chip technology are leading to smaller, more powerful components, allowing for sleeker prosthetic designs.

- AI Integration: Components with built-in artificial intelligence capabilities are enabling smarter prosthetics that adapt to user movements in real time.

- Wireless Power: Innovations in wireless charging technology are reducing the need for bulky batteries, improving user convenience.

By keeping an eye on these trends, you can future-proof your designs and offer cutting-edge solutions to users.

Conclusion: Building Better Prosthetics with the Right Components

Choosing the right components for your prosthetic device PCB is a complex but rewarding process. By focusing on functional requirements, power efficiency, durability, biocompatibility, and reliable sourcing, you can create a PCB that powers a prosthetic device with precision and safety. Thorough testing and staying informed about industry trends further ensure your design meets both current and future needs.

ALLPCB

ALLPCB