In the world of hotel room control systems, ensuring optimal signal integrity in PCB layouts is crucial for seamless operation. These systems manage everything from lighting and HVAC to door access and entertainment, requiring high-speed data transfer and minimal interference. So, how can you design a PCB layout for hotel room control systems that guarantees reliable performance? The answer lies in mastering techniques like high-speed PCB layout, impedance control, signal routing strategies, ground plane design, and minimizing EMI (electromagnetic interference). In this blog, we'll dive deep into these concepts, offering practical tips and detailed insights to help engineers create robust designs for hotel automation.

Why Signal Integrity Matters in Hotel Room Control Systems

Hotel room control systems rely on complex electronics to communicate between sensors, controllers, and actuators. A single glitch or signal delay can disrupt operations, leading to guest dissatisfaction or system failures. Signal integrity ensures that data signals travel without distortion, noise, or loss, maintaining the reliability of high-speed communications. For PCBs in these environments, factors like crosstalk, reflections, and EMI can degrade performance if not addressed during the design phase. Let's explore the key techniques to optimize your PCB layout for signal integrity, tailored specifically for hotel room control applications.

Understanding the Challenges in Hotel Room Control PCBs

Hotel room control systems often integrate multiple functions on a single PCB, including power management, communication protocols (like I2C or SPI), and wireless connectivity (such as Wi-Fi or Zigbee). These mixed-signal designs face unique challenges:

- High-Speed Signals: Data rates can exceed 100 Mbps for modern control systems, increasing the risk of signal degradation.

- Mixed Signals: Analog and digital signals on the same board can interfere with each other without proper isolation.

- Compact Designs: Space constraints in hotel room devices demand tight layouts, making EMI and crosstalk more likely.

- Environmental Noise: Hotels are full of potential EMI sources, from electrical appliances to wireless networks.

Addressing these challenges requires a strategic approach to PCB layout. Let's break down the essential techniques for achieving optimal signal integrity.

Key Techniques for High-Speed PCB Layout in Hotel Room Control Systems

High-speed PCB layout is the foundation of signal integrity. At data rates above 50 MHz, even small design flaws can cause signal reflections or timing issues. Here are some proven strategies for designing high-speed layouts:

- Minimize Trace Lengths: Keep signal traces as short as possible to reduce propagation delay and signal loss. For instance, a trace longer than 1 inch for a 100 MHz signal can introduce noticeable delays.

- Avoid Sharp Corners: Use 45-degree angles or rounded corners instead of 90-degree bends to prevent signal reflections. Sharp corners act as impedance discontinuities, disrupting high-speed signals.

- Maintain Consistent Trace Widths: Uniform trace widths prevent impedance mismatches. For a 50-ohm characteristic impedance (common in high-speed designs), calculate trace width based on your PCB stack-up and dielectric constant, typically around 6-8 mils for a standard FR-4 board.

Mastering Impedance Control for Reliable Signal Transmission

Impedance control is critical for ensuring that signals travel without reflections in high-speed PCB layouts. Mismatched impedance can cause signal distortion, especially in hotel room control systems where fast data transfer is essential for real-time responses. Here's how to achieve proper impedance control:

- Calculate Characteristic Impedance: Target a specific impedance value, such as 50 ohms for single-ended signals or 100 ohms for differential pairs, based on your design requirements. Use online calculators or simulation tools to determine trace width and spacing for your PCB material (e.g., FR-4 with a dielectric constant of 4.2).

- Use Controlled Stack-Up: Design your PCB stack-up with consistent layer thickness and dielectric materials. For example, a 4-layer board with signal layers on top and bottom, and power/ground planes in between, helps maintain impedance stability.

- Route Differential Pairs: For high-speed communication like USB or Ethernet in hotel control systems, route differential pairs with equal lengths and tight coupling to maintain impedance and reduce noise. A spacing of 5-10 mils between pair traces often works well for 100-ohm impedance.

By prioritizing impedance control, you ensure that signals arrive at their destination without distortion, even at speeds exceeding 100 Mbps.

Signal Routing Strategies to Prevent Crosstalk and Noise

Effective signal routing strategies are essential to avoid crosstalk and maintain signal integrity in hotel room control PCBs. Crosstalk occurs when adjacent traces interfere with each other, especially in high-speed designs. Follow these tips for clean signal routing:

- Space Traces Apart: Maintain a minimum spacing of 3 times the trace width (3W rule) between high-speed traces to reduce crosstalk. For a 6-mil trace, this means at least 18 mils of separation.

- Separate Analog and Digital Signals: Route analog and digital traces on different layers or areas of the board to prevent interference. For example, keep sensor inputs (analog) away from microcontroller data lines (digital).

- Use Guard Traces: Place grounded guard traces between sensitive high-speed lines to act as a shield against crosstalk. Connect these traces to the ground plane with vias at regular intervals (every 0.5 inches or so).

- Route Over Ground Planes: Ensure high-speed traces are routed over continuous ground planes to provide a return path and minimize loop inductance.

Implementing these routing strategies ensures that signals in your hotel room control system remain clear and free from interference, even in compact designs.

Ground Plane Design: The Backbone of Signal Integrity

A well-designed ground plane is vital for minimizing EMI and ensuring signal integrity in hotel room control PCBs. It provides a low-impedance return path for signals and helps shield against noise. Here's how to optimize your ground plane design:

- Use a Continuous Ground Plane: Avoid splitting the ground plane unless absolutely necessary. A solid ground plane under high-speed traces reduces EMI and provides a stable reference for signals. For a 4-layer board, dedicate an entire layer to ground.

- Place Vias Strategically: Use stitching vias to connect ground planes on different layers, keeping return paths short. Space vias every 0.2-0.5 inches near high-speed traces to minimize loop areas.

- Isolate Noisy Areas: If your PCB includes power electronics (e.g., for HVAC control), create separate ground regions for noisy components and connect them at a single point to the main ground to avoid noise coupling.

A robust ground plane design not only improves signal integrity but also reduces the risk of EMI, which is critical in hotel environments with multiple electronic devices.

Minimizing EMI in Hotel Room Control PCBs

Electromagnetic interference (EMI) can disrupt hotel room control systems, causing erratic behavior or communication failures. Minimizing EMI requires a combination of layout techniques and shielding strategies. Here are actionable steps to keep EMI in check:

- Reduce Loop Areas: Minimize the loop area between signal traces and their return paths by routing them over ground planes. Larger loops act as antennas, radiating EMI. For example, a loop area of 1 square inch can significantly increase emissions at 100 MHz.

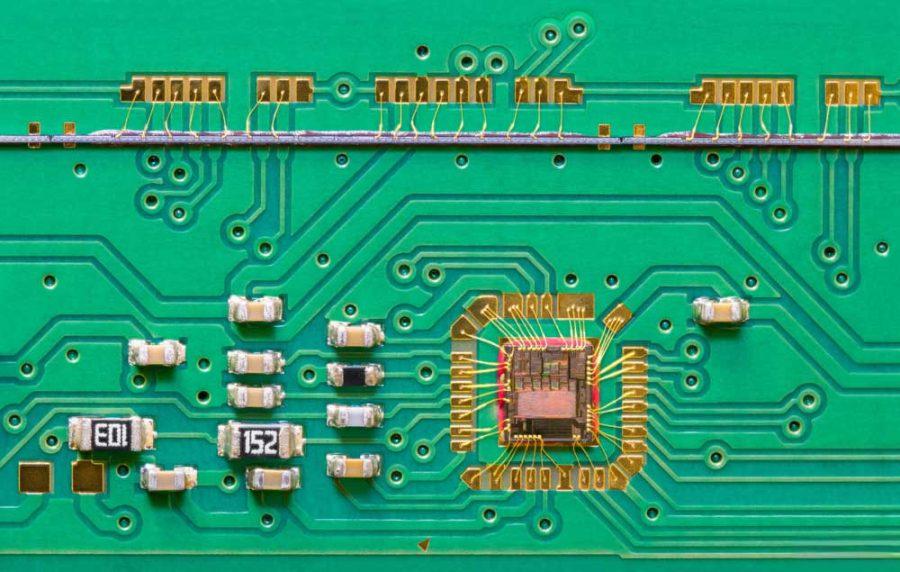

- Use Decoupling Capacitors: Place decoupling capacitors (e.g., 0.1 μF ceramic capacitors) near IC power pins to filter out high-frequency noise. Position them within 0.1 inches of the pins for maximum effectiveness.

- Shield Sensitive Components: Use metal enclosures or shielding cans around RF modules or sensitive analog circuits to block external EMI. Ensure the shield is connected to the ground plane.

- Filter Power Lines: Add ferrite beads and bypass capacitors on power entry points to suppress conducted EMI. A typical setup might include a 600-ohm ferrite bead with a 1 μF capacitor for noise filtering.

By focusing on minimizing EMI, you create a PCB design that operates reliably even in the noisy electrical environment of a hotel.

Practical Tips for Implementing These Techniques

Designing a PCB for hotel room control systems with optimal signal integrity requires attention to detail and careful planning. Here are some additional tips to bring it all together:

- Simulate Before Building: Use simulation software to analyze signal integrity, impedance, and EMI before manufacturing. Tools can predict issues like reflections or crosstalk, saving time and cost.

- Test in Real Conditions: After prototyping, test your PCB in a hotel-like environment with active electrical noise to validate performance. Measure signal quality using an oscilloscope to check for jitter or overshoot.

- Follow Industry Standards: Adhere to standards like IPC-2221 for PCB design to ensure reliability and manufacturability. These guidelines cover trace spacing, via sizes, and more.

By combining these practical steps with the techniques above, you can create a PCB layout that meets the demanding requirements of hotel room control systems.

Conclusion: Building Reliable Hotel Room Control Systems with Superior PCB Design

Designing a PCB for hotel room control systems is no small task, but focusing on signal integrity can make all the difference. By applying high-speed PCB layout techniques, mastering impedance control, using smart signal routing strategies, optimizing ground plane design, and minimizing EMI, you ensure reliable performance in even the most challenging environments. These methods not only prevent signal degradation but also enhance the overall user experience in hotel automation.

Whether you're working on a system for lighting control, access management, or HVAC automation, these layout techniques provide a solid foundation for success. With careful planning and attention to detail, your PCB designs can deliver seamless operation, keeping hotel systems running smoothly and guests satisfied. Start implementing these strategies in your next project to achieve optimal signal integrity and robust performance.

ALLPCB

ALLPCB