Flux application is a critical step in Surface Mount Technology (SMT) for PCB manufacturing. If you're looking to improve the quality of your surface mount assembly, understanding and optimizing SMT flux application techniques can make a significant difference. Whether it's through stencil printing or precise flux dispensing, the right approach ensures strong solder joints, reduces defects, and boosts production efficiency.

In this comprehensive guide, we'll dive deep into the best flux techniques for SMT, covering everything from the basics of flux in PCB manufacturing to advanced methods for optimizing application. Our goal is to provide actionable insights for engineers and manufacturers aiming to refine their processes. Let’s explore how to achieve reliable results in surface mount assembly with effective flux management.

What Is Flux and Why Is It Essential in SMT?

Flux is a chemical agent used in soldering to clean and prepare surfaces for a strong bond. In Surface Mount Technology, it plays a vital role by removing oxides and impurities from the PCB pads and component leads. This ensures better wetting of the solder, which is crucial for creating reliable electrical connections during surface mount assembly.

Without proper flux application, issues like poor solder joints, bridging, or tombstoning can occur, leading to costly rework or product failures. Flux also helps manage heat transfer during reflow soldering, preventing damage to sensitive components. In short, mastering SMT flux application is the foundation of high-quality PCB manufacturing.

Key Challenges in SMT Flux Application

Applying flux in SMT is not without its challenges. Manufacturers often face issues that can impact the quality of the final product. Some common problems include:

- Inconsistent Coverage: Uneven flux application can lead to weak solder joints or insufficient cleaning of surfaces.

- Excess Residue: Too much flux can leave behind sticky residues that attract dust or cause electrical shorts over time.

- Compatibility Issues: Not all fluxes work well with every solder paste or PCB material, leading to defects during reflow.

- Equipment Limitations: Poorly calibrated stencil printers or dispensing tools can result in inaccurate flux placement.

Addressing these challenges requires a deep understanding of flux techniques and the right tools for the job. Let’s look at the most effective methods for SMT flux application.

Popular Flux Application Techniques for SMT

There are several methods for applying flux in surface mount assembly, each with its own advantages depending on the production scale and specific requirements. Below, we’ll cover the most widely used techniques in PCB manufacturing.

1. Stencil Printing for Flux Application

Stencil printing is one of the most common methods for applying flux in SMT. It involves using a metal stencil with precise openings to deposit flux (often mixed with solder paste) onto the PCB pads. This technique is highly efficient for high-volume production.

How It Works: A squeegee pushes the flux or solder paste through the stencil apertures, ensuring uniform application only where needed. The stencil is then removed, leaving a controlled amount of material on the board.

Benefits:

- High precision for small components with tight tolerances.

- Consistent results across large batches, with studies showing defect rates as low as 0.5% when optimized.

- Fast application, often completing a board in under 10 seconds on modern equipment.

Optimization Tips:

- Use a stencil thickness of 0.1 to 0.15 mm for fine-pitch components to avoid excess flux.

- Regularly clean the stencil to prevent clogging, which can reduce application accuracy by up to 20% over time.

- Adjust squeegee pressure (typically 2-4 kg) to match the flux viscosity for even distribution.

2. Flux Dispensing with Automated Systems

Flux dispensing involves using automated equipment to apply flux directly onto specific areas of the PCB. This method is ideal for selective soldering or rework processes where stencil printing isn’t practical.

How It Works: A dispensing nozzle, controlled by a programmable system, deposits precise droplets of flux onto the target areas. The volume and placement can be fine-tuned to match the component layout.

Benefits:

- Highly customizable for complex or irregular PCB designs.

- Reduces waste by applying flux only where needed, potentially cutting material costs by 15-25% compared to stencil printing in low-volume runs.

- Works well for mixed-technology boards with both SMT and through-hole components.

Optimization Tips:

- Set dispensing speed to 50-100 mm/s for accurate placement without overspill.

- Use a needle with a 0.2-0.4 mm diameter for fine-pitch applications to control droplet size.

- Calibrate the system regularly to maintain placement accuracy within 0.05 mm.

3. Dip Fluxing for Specific Components

Dip fluxing is less common in full SMT assembly but is useful for specific components or rework. In this method, component leads or PCB areas are dipped into a flux reservoir before soldering.

How It Works: The PCB or component is carefully lowered into a thin layer of flux, coating only the necessary areas. Excess flux is often removed to prevent residue buildup.

Benefits:

- Simple and low-cost for small-scale or manual operations.

- Effective for targeted applications, such as connectors or large components.

Optimization Tips:

- Control immersion time to 1-2 seconds to avoid excess flux absorption.

- Use a low-residue flux to minimize cleaning requirements post-soldering.

Choosing the Right Flux for SMT Applications

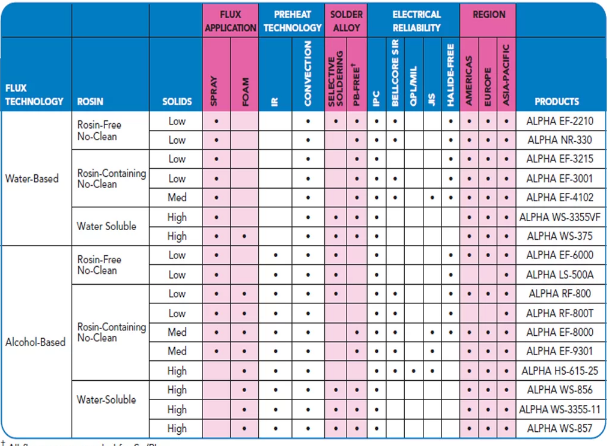

Not all fluxes are created equal, and selecting the right type is just as important as the application method. Fluxes are categorized based on their activity level and composition, which affect their performance in PCB manufacturing.

Types of Flux:

- Rosin-Based Flux: Offers good cleaning and wetting properties, ideal for general-purpose SMT. However, it often leaves a residue that may require cleaning.

- No-Clean Flux: Designed to leave minimal residue, reducing post-soldering cleanup. It’s widely used in high-volume production, with over 60% of manufacturers preferring it for SMT.

- Water-Soluble Flux: Highly active for tough oxides but requires thorough cleaning to prevent corrosion. Best for controlled environments.

Selection Tips:

- Match the flux activity to the solderability of your components. For example, use low-activity no-clean flux for pre-tinned surfaces to avoid over-activation.

- Consider the reflow profile—some fluxes degrade above 260°C, leading to defects if not matched to your process.

- Test compatibility with your solder paste, as mismatched materials can increase voiding rates by up to 30%.

Best Practices for Optimizing Flux Techniques in SMT

To achieve the best results in surface mount assembly, follow these proven practices for flux application. These tips are based on industry standards and can significantly reduce defect rates in PCB manufacturing.

- Maintain Equipment: Regularly inspect and clean stencil printers and dispensing nozzles. A study found that unmaintained equipment can increase flux misplacement by 18% over a single shift.

- Control Environment: Keep humidity between 40-60% and temperature at 20-25°C in the assembly area. Excess moisture can alter flux viscosity, affecting application consistency.

- Monitor Flux Volume: Use automated inspection systems to check flux thickness post-application. Aim for a uniform layer of 0.05-0.1 mm to balance cleaning and residue risks.

- Train Staff: Ensure operators understand flux properties and equipment settings. Proper training can cut application errors by nearly 40%, based on manufacturing feedback.

- Test and Iterate: Run small batches with new flux or techniques before full production. Document results to identify optimal settings, such as stencil aperture ratios or dispensing speeds.

Advanced Tools for SMT Flux Application

Modern technology offers advanced tools to enhance flux application precision in SMT. Investing in these can improve efficiency and reduce costs over time.

- Automated Optical Inspection (AOI): Post-application AOI systems can detect flux coverage issues with 99% accuracy, allowing immediate corrections before reflow.

- Jet Dispensing Systems: These non-contact dispensers apply flux at speeds up to 200 droplets per second, ideal for high-speed production with complex layouts.

- Laser-Cut Stencils: Offering aperture precision within 0.01 mm, laser-cut stencils ensure uniform flux application even for 0.4 mm pitch components.

Common Defects Caused by Poor Flux Application and How to Fix Them

Even with the best techniques, defects can occur if flux application isn’t optimized. Here are some frequent issues in surface mount assembly and their solutions.

- Solder Bridging: Caused by excess flux or solder paste connecting adjacent pads. Reduce flux volume and ensure stencil apertures are correctly sized (typically 1:1 ratio to pad size).

- Insufficient Wetting: Results from too little flux or low activity. Switch to a higher-activity flux and verify application coverage using inspection tools.

- Residue Buildup: Often linked to rosin-based fluxes. Transition to no-clean options or implement a post-soldering cleaning process with isopropyl alcohol.

The Future of Flux Application in SMT

As PCB manufacturing evolves, so do flux techniques. Emerging trends include the use of low-temperature fluxes for heat-sensitive components and eco-friendly formulations to meet regulatory standards. Additionally, advancements in automation, such as AI-driven dispensing systems, promise to further refine precision, potentially reducing flux-related defects by up to 50% in the next decade.

Staying ahead means adopting these innovations while maintaining a strong foundation in current best practices. By focusing on both, manufacturers can ensure consistent quality in surface mount assembly.

Conclusion: Mastering SMT Flux Application for Better Results

Optimizing flux application techniques is a game-changer for Surface Mount Technology. Whether you rely on stencil printing for high-volume runs or precise flux dispensing for complex designs, the right approach can minimize defects, improve solder joint reliability, and streamline your PCB manufacturing process.

Start by evaluating your current flux techniques and identifying areas for improvement. Test different methods, maintain your equipment, and choose the right flux for your specific needs. With these steps, you’ll be well on your way to achieving top-tier results in surface mount assembly. Trust in proven practices and innovative tools to elevate your production quality to new heights.

ALLPCB

ALLPCB