If you're searching for clarity on ASTM soldering standards for PCB assembly, you've come to the right place. ASTM standards provide critical guidelines for ensuring solder joint reliability, optimizing reflow and wave soldering processes, and testing solder paste. In this comprehensive guide, we'll break down the key ASTM standards relevant to PCB soldering and assembly, helping you achieve high-quality, reliable results in your projects. Whether you're focused on solder joint reliability per ASTM guidelines, reflow soldering process control, or wave soldering standards, this blog covers it all with actionable insights.

Introduction to ASTM Standards in PCB Soldering and Assembly

When it comes to manufacturing printed circuit boards (PCBs), quality and reliability are non-negotiable. Soldering, a fundamental process in PCB assembly, directly impacts the performance and longevity of electronic devices. This is where ASTM International standards come into play. ASTM, formerly known as the American Society for Testing and Materials, develops globally recognized standards to ensure consistency, safety, and quality across industries, including electronics manufacturing.

For PCB soldering and assembly, ASTM standards offer detailed specifications for materials, processes, and testing methods. These standards help engineers and manufacturers maintain solder joint reliability, control soldering processes like reflow and wave soldering, and evaluate critical materials such as solder paste. By adhering to ASTM guidelines, you can minimize defects, improve product durability, and meet industry expectations.

In this ultimate guide, we'll dive deep into the specific ASTM standards that apply to PCB soldering and assembly. We'll explore their role in ensuring solder joint reliability, optimizing reflow soldering process control, defining wave soldering standards, and conducting solder paste testing. Let's get started with the fundamentals.

What Are ASTM Soldering Standards for PCB Assembly?

ASTM soldering standards for PCB assembly are a set of guidelines and test methods designed to ensure the quality and reliability of soldered connections on circuit boards. These standards cover everything from the materials used in soldering to the processes and testing protocols that verify the integrity of solder joints.

Some key ASTM standards relevant to PCB assembly include:

- ASTM B579: Focuses on electrodeposited coatings of tin-lead alloys, often used in soldering applications for PCBs.

- ASTM B678: Provides test methods for assessing the solderability of metallic-coated products, which is crucial for ensuring proper bonding during PCB assembly.

- ASTM E1335: Outlines test methods for evaluating the performance of solder paste, a critical material in surface mount technology (SMT) assembly.

These standards are essential for manufacturers aiming to produce high-quality PCBs with reliable solder joints. By following ASTM guidelines, you can reduce the risk of common issues like cold solder joints, insufficient wetting, or thermal stress failures. In the following sections, we'll explore how these standards apply to specific aspects of PCB soldering and assembly.

Solder Joint Reliability Under ASTM Standards

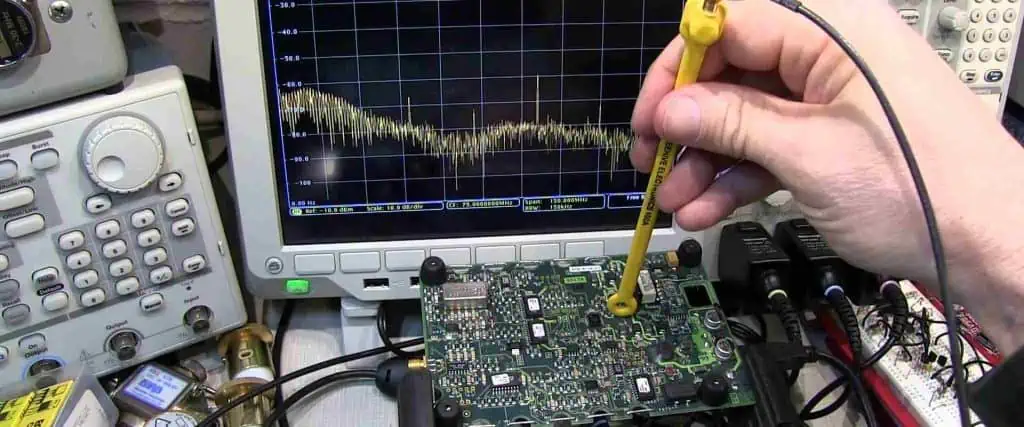

Solder joint reliability is a critical concern in PCB assembly, as the strength and durability of these joints determine the overall performance of electronic devices. ASTM standards provide detailed test methods and criteria to evaluate and ensure solder joint reliability under various conditions.

One key aspect of solder joint reliability per ASTM guidelines is thermal cycling testing. This process subjects solder joints to repeated temperature changes to simulate real-world operating conditions. ASTM standards specify acceptable limits for thermal stress and fatigue, helping manufacturers identify potential weaknesses in their soldering processes. For instance, a typical thermal cycling test might range from -40°C to 125°C over 1000 cycles to assess joint durability.

Additionally, ASTM standards like ASTM B678 help evaluate solderability by measuring the wetting behavior of solder on component leads and PCB pads. Poor wetting can lead to weak joints, increasing the risk of failure. By adhering to these standards, manufacturers can ensure that solder forms strong, reliable bonds with minimal defects.

Implementing ASTM standards for solder joint reliability also involves mechanical testing. This includes shear and pull tests to measure the strength of solder joints under physical stress. For example, a shear test might apply a force of up to 5 kg to a soldered component to ensure it withstands handling and operational stresses.

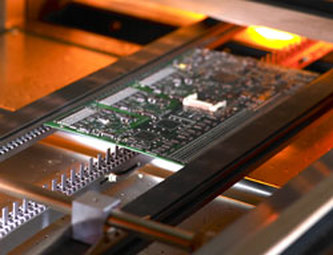

Reflow Soldering Process Control with ASTM Guidelines

Reflow soldering is a widely used technique in surface mount technology (SMT) for attaching components to PCBs. It involves applying solder paste, placing components, and heating the assembly in a reflow oven to melt the solder and form strong joints. Controlling the reflow soldering process is crucial for achieving consistent results, and ASTM standards provide valuable guidance in this area.

ASTM standards indirectly support reflow soldering process control by defining material properties and testing methods that influence the process. For example, ASTM E1335 helps evaluate the performance of solder paste under reflow conditions, ensuring it melts and flows properly at specified temperatures. A typical reflow profile for lead-free solder paste might include a preheat stage at 150-180°C for 60-90 seconds, a peak temperature of 235-245°C, and a time above liquidus of 30-60 seconds.

By following ASTM guidelines for material testing, manufacturers can optimize their reflow profiles to prevent common defects like tombstoning, where components lift off the board, or insufficient soldering due to low temperatures. Proper process control also minimizes thermal stress on components, extending the lifespan of the assembled PCB.

To achieve effective reflow soldering process control, manufacturers should regularly test solder paste viscosity and printability as per ASTM methods. For instance, a solder paste with a viscosity of 800-1000 kcps (kilo centipoise) is often ideal for stencil printing in reflow soldering, ensuring precise application and uniform joints.

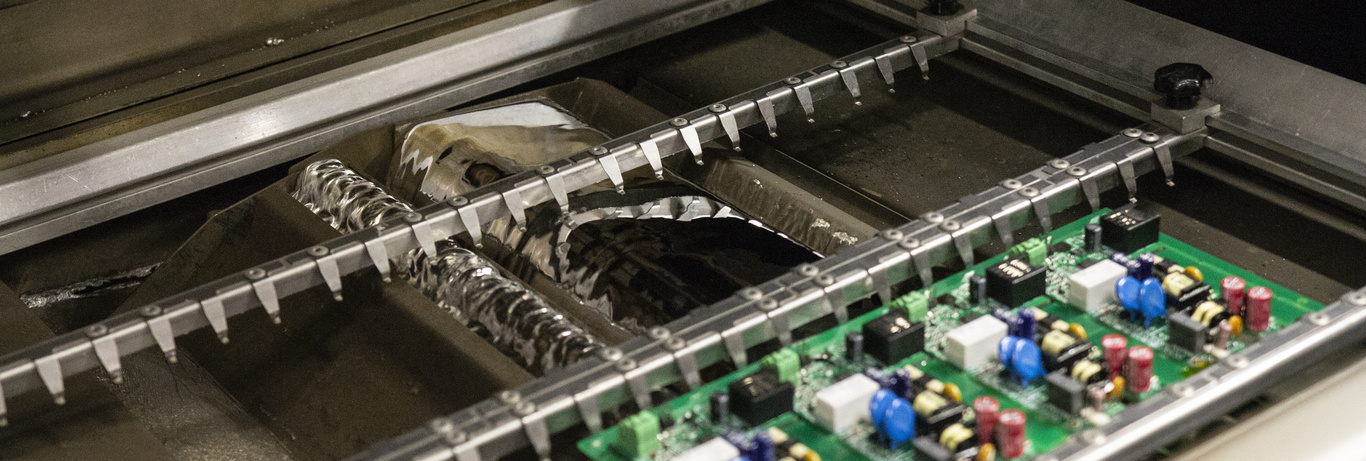

Wave Soldering Standards and Best Practices

Wave soldering is another common method used in PCB assembly, particularly for through-hole components. In this process, a wave of molten solder passes over the bottom of the PCB, creating joints between component leads and the board. ASTM standards play a vital role in defining wave soldering standards to ensure consistent quality and reliability.

ASTM B678, which focuses on solderability testing, is particularly relevant for wave soldering. This standard helps determine whether component leads and PCB pads can be adequately wetted by molten solder during the wave soldering process. Proper wetting is essential for forming strong, defect-free joints. For example, a solderability test might involve dipping a component lead into molten solder at 235°C for 5 seconds to check for complete coverage.

Wave soldering standards also emphasize the importance of controlling process parameters like solder temperature, conveyor speed, and flux application. A typical wave soldering setup might maintain a solder pot temperature of 250-260°C for lead-free alloys, with a contact time of 2-4 seconds between the PCB and the solder wave. Adhering to ASTM guidelines for material preparation and testing helps manufacturers fine-tune these parameters for optimal results.

By following wave soldering standards, you can avoid issues like bridging, where excess solder connects adjacent pads, or insufficient soldering due to poor flux activation. Regular testing of materials and process monitoring are key to maintaining high-quality output in wave soldering.

Solder Paste Testing Under ASTM Standards

Solder paste is a critical material in SMT assembly, acting as both an adhesive and a conductor during the reflow process. Testing solder paste for quality and performance is essential to ensure reliable soldering, and ASTM standards provide standardized methods for these evaluations.

ASTM E1335 is a key standard for solder paste testing, covering aspects like slump, tackiness, and solder ball formation. Slump testing, for instance, measures how much the solder paste spreads after printing, which affects the precision of component placement. A slump value of less than 0.2 mm is often considered acceptable for fine-pitch applications.

Tackiness testing under ASTM guidelines evaluates the ability of solder paste to hold components in place before reflow. A tack force of 1-2 grams is typically sufficient to secure small components during handling. Additionally, solder ball testing checks for the formation of unwanted solder balls during reflow, which can cause short circuits. ASTM standards specify acceptable limits, often requiring fewer than 5 solder balls per square inch after reflow.

By conducting solder paste testing per ASTM standards, manufacturers can select the right paste for their specific applications and avoid common soldering defects. Regular testing also helps maintain consistency across production batches, ensuring uniform quality in PCB assembly.

Why Adhering to ASTM Standards Matters for PCB Manufacturers

Following ASTM standards in PCB soldering and assembly offers several benefits for manufacturers. First, it ensures product reliability by minimizing defects and failures in solder joints. This is especially important for industries like aerospace, automotive, and medical, where even a single failed connection can have serious consequences.

Second, ASTM standards help manufacturers meet regulatory and customer requirements. Many clients specify compliance with industry standards as a condition for contracts, and adhering to ASTM guidelines demonstrates a commitment to quality and professionalism.

Finally, using ASTM standards streamlines the manufacturing process by providing clear, repeatable methods for testing and process control. This reduces variability, improves yield rates, and lowers production costs over time. For example, consistent solder paste testing can prevent rework rates from exceeding 2-3%, saving significant time and resources.

Practical Tips for Implementing ASTM Standards in PCB Soldering

Implementing ASTM standards in your PCB soldering and assembly processes doesn't have to be complicated. Here are some practical tips to get started:

- Invest in Training: Ensure your team is familiar with relevant ASTM standards and testing methods. Regular training sessions can keep everyone updated on best practices.

- Use Certified Materials: Source solder paste, flux, and other materials from suppliers that meet ASTM specifications to guarantee quality from the start.

- Monitor Process Parameters: Use data logging tools to track temperatures, times, and other variables during reflow and wave soldering. Compare these against ASTM-recommended limits for consistency.

- Conduct Regular Testing: Perform solderability, slump, and tackiness tests as per ASTM guidelines to catch issues early and maintain quality control.

- Document Results: Keep detailed records of test results and process adjustments to identify trends and improve over time.

By integrating these practices into your workflow, you can achieve reliable, high-quality soldering results while staying compliant with ASTM standards.

Conclusion: Elevate Your PCB Assembly with ASTM Standards

ASTM standards are invaluable tools for ensuring quality and reliability in PCB soldering and assembly. From guaranteeing solder joint reliability to optimizing reflow soldering process control and defining wave soldering standards, these guidelines cover every aspect of the soldering process. Solder paste testing under ASTM standards further ensures that materials perform as expected, reducing defects and improving overall product quality.

By understanding and implementing ASTM soldering standards for PCB assembly, manufacturers can produce durable, high-performing electronic products that meet industry demands. Whether you're a seasoned engineer or new to PCB manufacturing, following these standards is a proven way to enhance your processes and deliver exceptional results.

At ALLPCB, we're committed to supporting your PCB assembly needs with resources and expertise aligned with industry standards. Explore our services to see how we can help you achieve soldering excellence in your next project.

ALLPCB

ALLPCB