Overview

In power grid operations, partial discharge (PD) is an early indicator of insulation degradation in electrical equipment. The timeliness and accuracy of PD monitoring data directly affect the safety margin of the power system. Real-time PD monitoring sensors for the power grid serve as key state-awareness devices, continuously capturing small discharge signals inside equipment to support maintenance decision making. This article analyzes the practical value of these sensors from the perspectives of technical characteristics, application scenarios, and technical optimization.

Sensing Capabilities

The core of PD monitoring is accurate capture of high-frequency electrical signals, ultrasound, and electromagnetic emissions. Sensors use built-in wideband detection units that cover signal bands from tens of kilohertz to several gigahertz, enabling monitoring of different discharge types such as surface discharge, internal discharge, and corona discharge. Data acquisition modules employ adaptive filtering algorithms to extract valid signals under strong electromagnetic interference. Digital signal processing techniques are then used for noise suppression and feature extraction, ultimately generating quantifiable PD amplitude, occurrence frequency, and phase information.

Application Scenarios in Power Grids

In grid environments, real-time monitoring sensors provide multi-dimensional risk control. Deployed on transformers, switchgear, cable joints, and other key equipment, sensors can form comprehensive monitoring networks that dynamically track PD activity. For example, during transformer operation PD data can reflect aging of the insulation oil-paper system and serve as auxiliary validation for oil chromatography. In high-voltage cable lines, real-time monitoring data can help locate insulation defects and guide maintenance personnel for targeted live-line testing or local repairs.

Technical Optimization

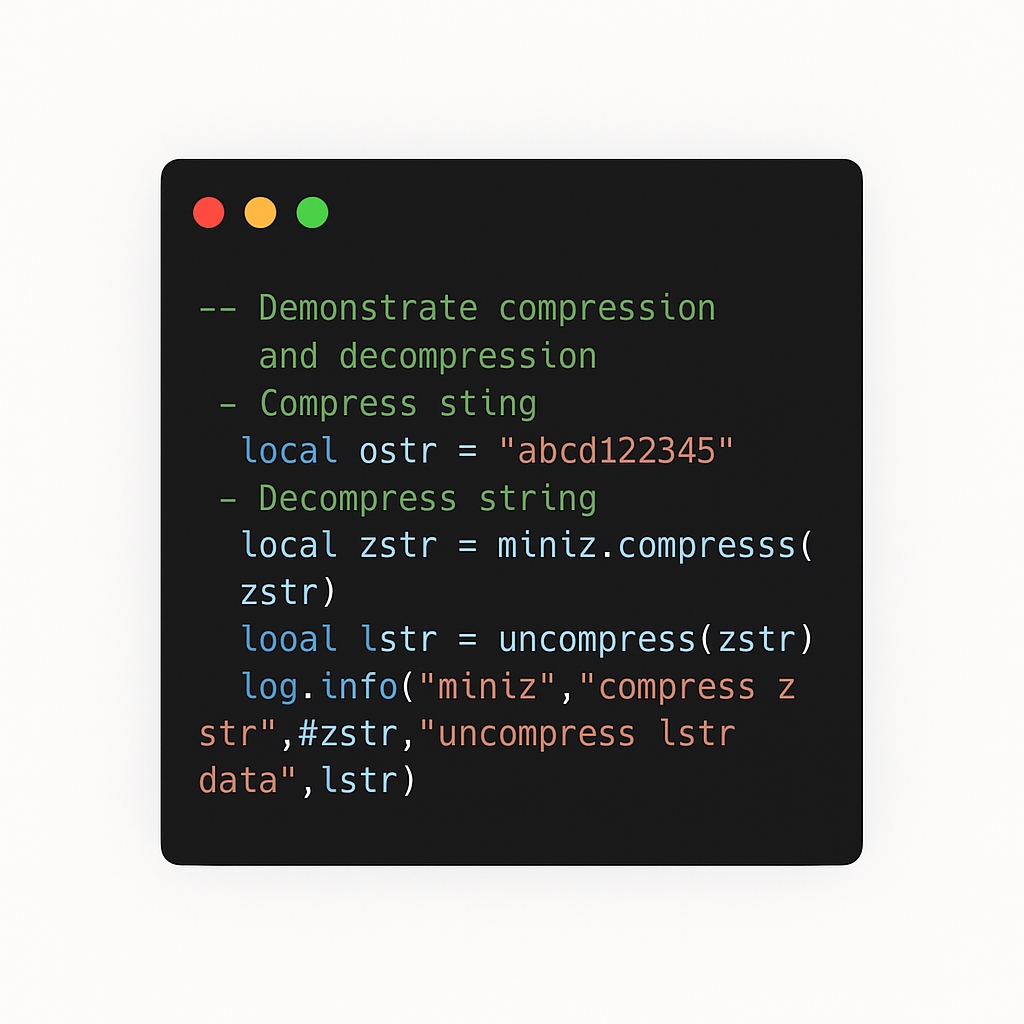

Sensors must balance sensitivity and interference immunity. Industrial environments contain substantial power-frequency interference, switching overvoltages, and other noise sources, so sensors typically use shielded structural designs and differential signal acquisition to improve signal-to-noise ratio. Integration of edge computing modules provides basic local data processing capabilities, enabling local data compression, abnormal-event triggering, and preliminary diagnostics. These functions reduce data transmission load and improve response time.

Integration with Monitoring Platforms

In maintenance practice, sensors should form a collaborative system with intelligent monitoring platforms. Through standardized communication protocols, monitoring data can be integrated into grid dispatch centers or equipment health management systems for visualization and trend analysis. Combined with historical operation data and operating parameters, maintenance personnel can build correlation models between PD activity and equipment condition to quantify fault risk and optimize maintenance strategies.

Future Directions

As digital twin and artificial intelligence technologies converge, PD monitoring sensors are expected to evolve toward greater intelligence. Building device digital twin models enables dynamic simulation and risk prediction of PD activity. Combined with machine learning algorithms, these capabilities can improve the proactiveness and accuracy of grid maintenance.

Conclusion

Real-time PD monitoring sensors are core equipment for power equipment state awareness. Through ongoing technical innovation and scenario adaptation they provide reliable support for secure grid operation and serve as a key technical foundation for building a state-awareness system for the smart grid.

ALLPCB

ALLPCB