Overview

In power transmission networks, overhead insulated cables are a primary medium for energy delivery, and their condition directly affects supply reliability. As operating environments become more complex, partial discharge monitoring has become a core method for assessing cable insulation performance. This article focuses on the transient earth voltage detection principle and analyzes the technical characteristics and engineering applications of partial discharge sensors for overhead insulated cables.

Transient Earth Voltage Detection Principle

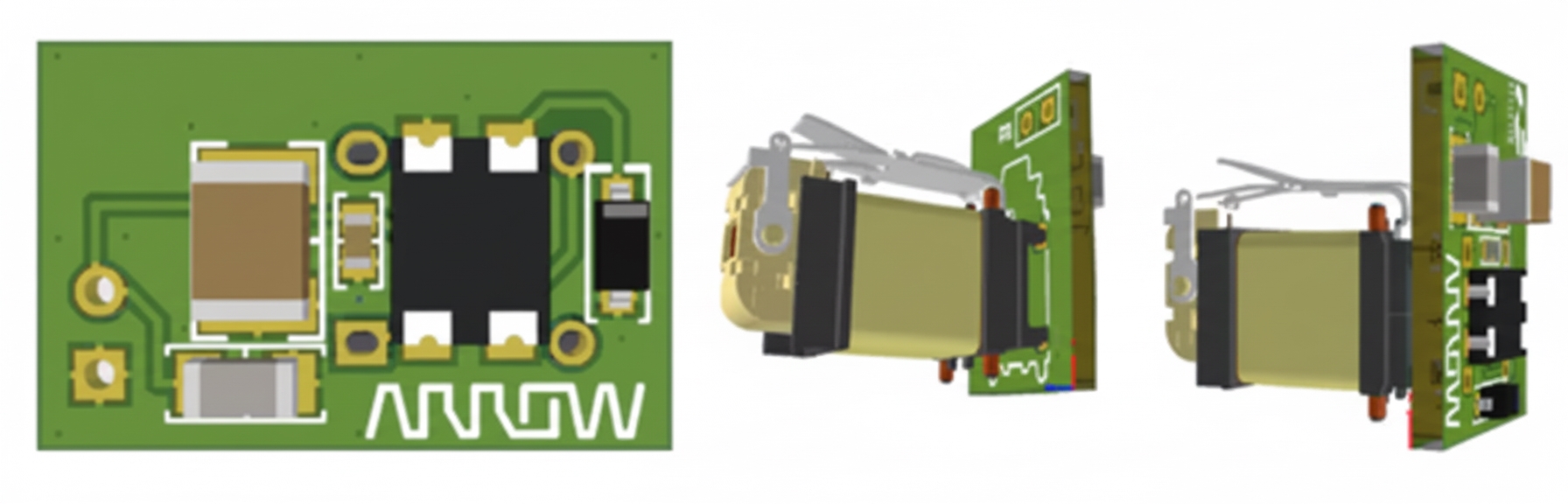

Transient earth voltage detection is based on electromagnetic coupling. A sensor's internal high-sensitivity capacitive coupling unit captures partial discharge signals generated at cable joints, terminations, and similar locations. When insulation defects cause partial discharge, transient voltage pulses occur between the metallic shield and grounded structures. The sensor couples these pulses and converts them into measurable electrical signals. A non-intrusive magnetic mounting method fixes the sensor to the cable metal shield surface via a strong magnetic base, enabling real-time monitoring without de-energizing the line, which is especially suitable for retrofitting energized lines.

Signal Acquisition and Processing

The sensor uses a wideband design to accurately capture the ultra-high-frequency electromagnetic pulses generated by different types of partial discharge. An internal adaptive filtering algorithm dynamically adjusts detection thresholds according to the local electromagnetic environment, effectively suppressing environmental noise. Time-frequency joint analysis techniques separate normal operational electromagnetic pulses from fault discharge signals, ensuring monitoring data are accurate and reliable.

Mechanical and Environmental Design

The modular design encapsulates each functional unit independently and connects them via standardized interfaces, supporting hot-plug maintenance. The enclosure is made of high-strength, weather-resistant composite material and is certified to a protection rating suitable for outdoor harsh environments. Built-in temperature compensation and humidity monitoring units mitigate the effects of ambient temperature and humidity changes on detection sensitivity, ensuring continuous and comparable data across different environmental conditions.

Data Analysis and Diagnostics

An intelligent data analysis platform supports time-space synchronization of multi-sensor data and 3D visualization. Machine learning algorithms model historical discharge data to predict cable insulation aging trends, providing a basis for condition-based maintenance. The diagnostic system automatically generates reports that include severity and trend assessments, helping operations staff quickly locate fault sources and improve fault response efficiency.

Operational Impact

By applying transient earth voltage detection, partial discharge sensors help shift maintenance from reactive repair to proactive prevention. Their non-intrusive installation, wideband detection, and diagnostic capabilities offer a technical path for continuous cable insulation condition awareness and contribute to improved grid maintenance automation. With deeper integration of IoT and artificial intelligence technologies, the field is expected to see broader development prospects.

ALLPCB

ALLPCB