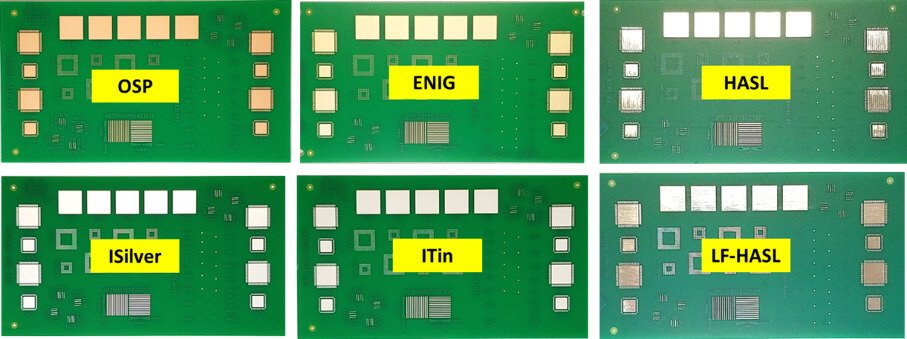

When it comes to surface mount technology (SMT) assembly, selecting the right surface finish for your printed circuit board (PCB) is a critical decision. Two popular options, immersion tin and organic solderability preservative (OSP), often come up in discussions due to their cost-effectiveness and compatibility with SMT processes. So, which one is better for your project? In short, immersion tin offers superior shelf life and durability for multiple reflow cycles, making it ideal for complex assemblies, while OSP is an eco-friendly, low-cost option best suited for simpler designs with quick turnaround times. In this detailed guide, we’ll dive deep into the differences between immersion tin and OSP, focusing on their impact on solder paste application, component placement, reflow profiles, and solder joint quality to help you make an informed choice.

Introduction to Surface Finishes in SMT Assembly

Surface finishes play a vital role in PCB manufacturing, especially in SMT assembly. They protect the exposed copper on the board from oxidation and ensure proper solderability during the assembly process. A good surface finish enhances the quality of solder joints, supports accurate component placement, and withstands the thermal stresses of reflow soldering. Among the many options available, immersion tin and OSP stand out for their unique benefits and challenges. Understanding how these finishes perform in SMT processes like solder paste application and reflow profiling is key to achieving reliable results. Let’s break down each finish and compare their characteristics for SMT applications.

What is Immersion Tin?

Immersion tin, sometimes referred to as white tin, is a surface finish applied to PCBs through an electroless chemical process. This method deposits a thin layer of tin—typically between 0.8 to 1.2 micrometers—over the copper pads. The result is a flat, uniform surface that protects the copper from oxidation and provides excellent solderability for SMT assembly. According to industry standards like IPC-4554, this thickness range ensures reliable solder joints while minimizing the risk of tin whisker growth, a phenomenon that can cause short circuits over time.

Immersion tin is particularly valued in applications requiring multiple reflow cycles, as it maintains its solderability even after prolonged storage. Its durability makes it a preferred choice for complex designs with fine-pitch components, where precision in component placement and solder joint quality is paramount.

What is OSP (Organic Solderability Preservative)?

OSP, or organic solderability preservative, is an organic coating applied to PCB copper pads to prevent oxidation. This finish forms a thin, transparent layer—often less than 0.5 micrometers thick—that acts as a barrier until the soldering process. During reflow, the OSP layer breaks down, allowing the solder paste to bond directly with the underlying copper. This makes OSP a cost-effective and environmentally friendly option, as it contains no heavy metals and requires minimal equipment maintenance.

OSP is widely used in high-volume production where boards are assembled shortly after manufacturing. However, its shelf life is shorter compared to immersion tin, typically around 6 to 12 months, and it may not withstand multiple reflow cycles as effectively, which can impact solder joint quality in complex assemblies.

Comparing Immersion Tin and OSP for SMT Assembly

To choose the right surface finish for your SMT project, it’s essential to evaluate how immersion tin and OSP perform across key aspects of the assembly process. Below, we’ll compare them based on solder paste application, component placement, reflow profile compatibility, and solder joint quality.

1. Solder Paste Application

Solder paste application is the first step in SMT assembly, where a mixture of solder alloy and flux is applied to the PCB pads using a stencil. The surface finish influences how evenly the paste adheres and spreads. Immersion tin provides a smooth, metallic surface that promotes consistent solder paste deposition, reducing the risk of defects like insufficient solder or bridging. Its tin layer also interacts well with common solder alloys like SAC305 (Sn96.5Ag3.0Cu0.5%), ensuring good wetting during reflow.

OSP, on the other hand, relies on the organic coating to protect the copper until soldering. While it generally supports adequate solder paste application, the organic layer can sometimes lead to uneven wetting if not handled properly. This is especially true if the board has been stored for too long, as the OSP coating may degrade, impacting paste adhesion.

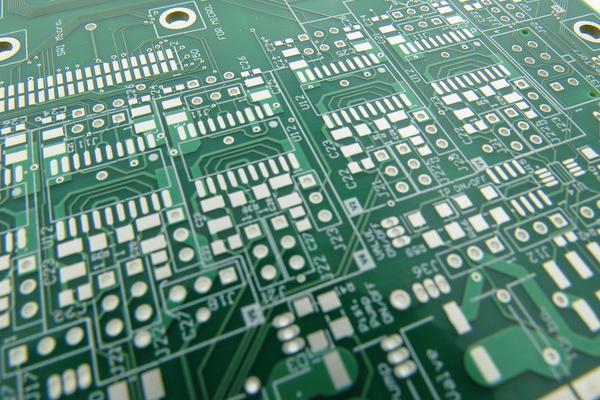

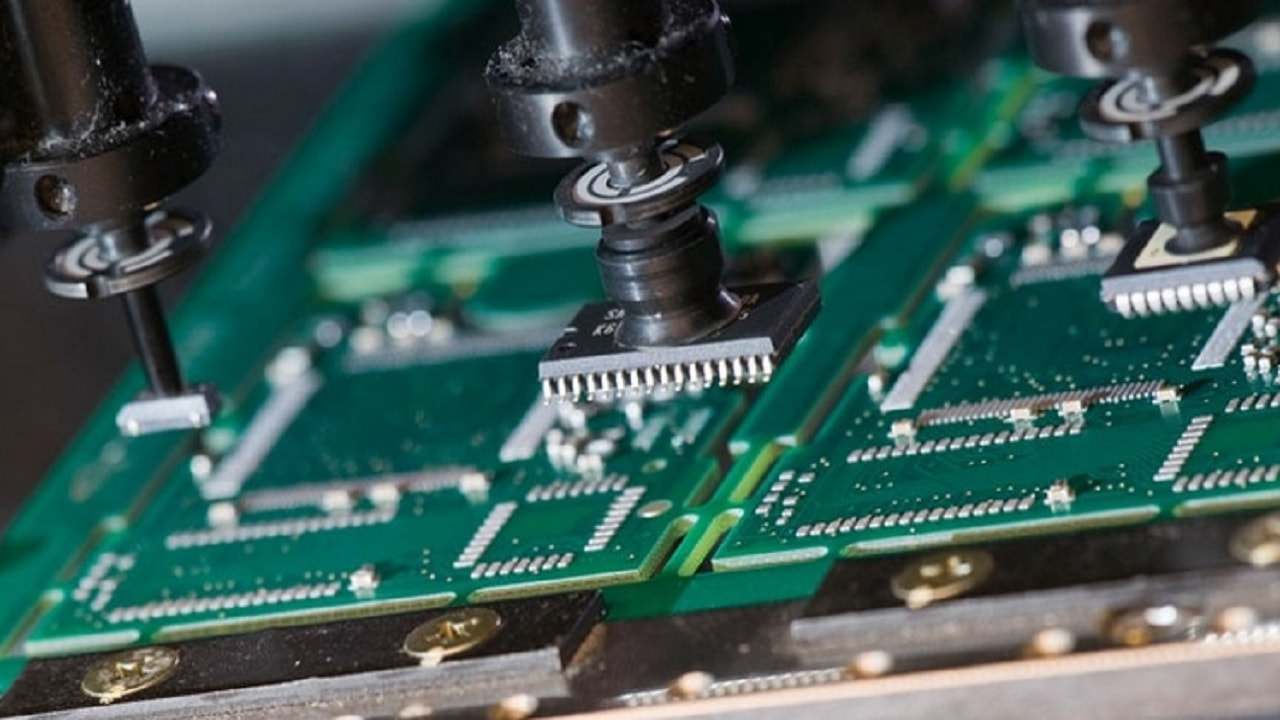

2. Component Placement

Accurate component placement is critical in SMT assembly, especially for fine-pitch components like QFPs or BGAs. The surface finish affects how components sit on the pads before reflow. Immersion tin’s flat, robust surface offers excellent stability for components, minimizing misalignment during placement. Its durability also ensures that pads remain intact even under slight mechanical stress from pick-and-place machines.

OSP provides a coplanar surface as well, which aids in component placement. However, its organic nature makes it more sensitive to handling. Fingerprints, moisture, or other contaminants can degrade the coating, potentially causing issues with component alignment or adhesion before reflow. Proper storage and handling are crucial when using OSP to maintain placement accuracy.

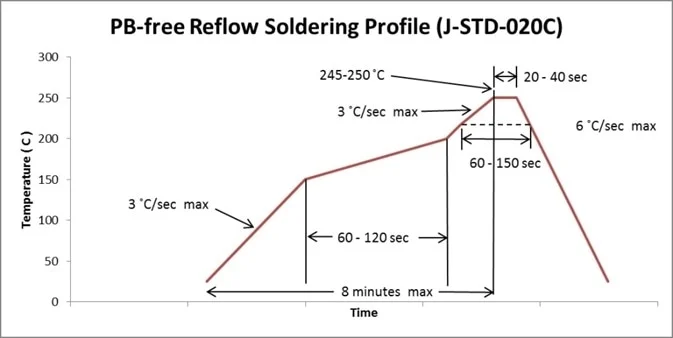

3. Reflow Profile Compatibility

The reflow profile—the temperature curve used to melt and solidify solder paste—must be tailored to the surface finish to avoid defects. Immersion tin is highly compatible with standard reflow profiles for both lead-free and leaded solders. It can withstand peak temperatures of 260°C for lead-free processes and maintains solderability through multiple reflow cycles, making it suitable for double-sided assemblies or rework.

OSP also works well with typical reflow profiles, with the organic layer dissipating at temperatures above 150°C, allowing direct copper-to-solder bonding. During reflow, tin and copper atoms form a Cu6Sn5 intermetallic compound (IMC) at the interface, which is essential for strong solder joints. However, OSP’s performance can degrade if the board undergoes multiple reflow cycles, as the exposed copper may oxidize without the protective coating, leading to poor wetting.

4. Solder Joint Quality

Solder joint quality determines the reliability and longevity of an SMT assembly. Immersion tin excels in this area due to its consistent tin layer, which forms a strong IMC with solder alloys. The tin-copper interface minimizes voiding and ensures robust mechanical and electrical connections. Studies suggest that immersion tin can achieve defect rates as low as 0.5% in high-volume SMT production when paired with optimized reflow profiles.

OSP can produce high-quality solder joints as well, particularly in single-reflow applications. The direct copper-solder bond results in a reliable IMC layer, with defect rates often below 1% under ideal conditions. However, its shorter shelf life and sensitivity to handling can lead to oxidation, increasing the risk of weak joints or solderability issues if not managed properly.

Pros and Cons of Immersion Tin for SMT Assembly

Pros:

- Long shelf life (up to 12-18 months), ideal for delayed assembly.

- Supports multiple reflow cycles without degradation.

- Excellent for fine-pitch components due to flat, durable surface.

- Consistent solderability, reducing defect rates in solder paste application.

Cons:

- Higher cost compared to OSP due to chemical deposition process.

- Risk of tin whisker growth over time, though minimized with proper thickness control (0.8-1.2 μm).

Pros and Cons of OSP for SMT Assembly

Pros:

- Low-cost and environmentally friendly, free of heavy metals.

- Provides a coplanar surface for accurate component placement.

- Simple process requiring minimal equipment maintenance.

Cons:

- Shorter shelf life (6-12 months), not ideal for long-term storage.

- Sensitive to handling and environmental conditions, risking oxidation.

- Limited suitability for multiple reflow cycles, impacting solder joint quality in complex assemblies.

Which Surface Finish Should You Choose for SMT Assembly?

Deciding between immersion tin and OSP depends on your project’s specific requirements. If you’re working on a complex design with fine-pitch components, multiple reflow cycles, or a need for extended shelf life, immersion tin is likely the better choice. Its durability and consistent performance across SMT processes like solder paste application and reflow ensure high solder joint quality, even in demanding applications.

On the other hand, if cost savings and environmental impact are priorities, and your project involves quick assembly turnaround with simpler designs, OSP offers a practical solution. Its low cost and ease of use make it a go-to option for high-volume production, provided proper storage and handling practices are followed to maintain solderability.

Consider factors like production volume, assembly timeline, and component complexity when making your decision. For instance, in automotive or medical electronics where reliability is non-negotiable, immersion tin’s robustness might outweigh its higher cost. Conversely, for consumer electronics with short product cycles, OSP’s affordability could be more advantageous.

Best Practices for SMT Assembly with Immersion Tin and OSP

To maximize the benefits of either surface finish, follow these best practices during SMT assembly:

- For Immersion Tin: Monitor tin thickness during manufacturing to stay within the 0.8-1.2 μm range, reducing the risk of tin whiskers. Use X-ray fluorescence analysis if possible to verify thickness, as recommended by industry standards.

- For OSP: Store boards in a controlled environment (temperature below 30°C, humidity below 60%) to prevent coating degradation. Minimize handling to avoid contamination of the organic layer.

- For Both: Optimize your reflow profile to match the surface finish and solder alloy. For lead-free soldering, aim for a peak temperature of 245-260°C with a time above liquidus (TAL) of 30-60 seconds to ensure proper wetting and IMC formation.

Conclusion

Choosing between immersion tin and OSP for SMT assembly involves weighing their strengths and limitations in the context of your specific project needs. Immersion tin stands out for its durability, long shelf life, and suitability for complex assemblies, making it a reliable choice for high-stakes applications. OSP, with its cost-effectiveness and eco-friendly nature, is perfect for simpler designs and fast-paced production environments, provided handling and storage are managed carefully.

By understanding how these surface finishes impact solder paste application, component placement, reflow profiles, and solder joint quality, you can make a decision that enhances the performance and reliability of your SMT assemblies. Whether you prioritize robustness or affordability, both immersion tin and OSP have a place in modern PCB manufacturing, and selecting the right one can significantly improve your production outcomes.

ALLPCB

ALLPCB