If you're new to electronics design or PCB assembly, you might be wondering, "What are SMT components, and how do I get started with them?" Surface Mount Technology (SMT) is a method for mounting electronic components directly onto the surface of a printed circuit board (PCB). This guide will introduce you to the basics of SMT components like resistors, capacitors, diodes, and transistors, helping you understand their roles and how to work with these surface mount devices in your projects.

In this comprehensive blog, we'll break down the essentials of SMT, explore the most common components, and provide practical tips for beginners. Whether you're a hobbyist or an aspiring engineer, this guide will equip you with the knowledge to confidently dive into the world of surface mount devices.

What is Surface Mount Technology (SMT)?

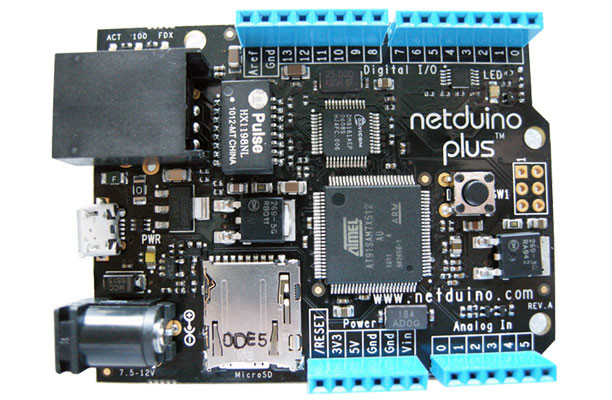

Surface Mount Technology, or SMT, is a technique used in electronics manufacturing to place components directly onto the surface of a PCB. Unlike traditional through-hole technology, where component leads are inserted into holes on the board, SMT components are soldered onto pads on the PCB's surface. This allows for smaller, more compact designs, which is why SMT is the go-to method for modern electronics like smartphones, laptops, and IoT devices.

SMT offers several advantages, including reduced board size, faster assembly, and the ability to place components on both sides of a PCB. However, working with SMT components requires precision due to their small size—some are just a few millimeters long! As a beginner, understanding the basic SMT components is the first step to mastering this technology.

Why Choose SMT Over Through-Hole Technology?

Before diving into specific SMT components, let’s look at why this technology is preferred in modern electronics:

- Smaller Size: SMT components are much smaller than through-hole components, enabling compact designs. For instance, an SMT resistor might measure just 1.6mm x 0.8mm in a 0603 package size.

- Higher Component Density: You can fit more components on a single PCB, ideal for complex circuits.

- Cost-Effective for Mass Production: Automated SMT assembly reduces labor costs in large-scale manufacturing.

- Better Performance: Shorter lead lengths in SMT components reduce parasitic inductance and capacitance, improving signal integrity at high frequencies (e.g., above 100 MHz in some designs).

While SMT may seem daunting due to the tiny size of components, the benefits make it worth learning. Let’s explore the basic SMT components you’ll encounter.

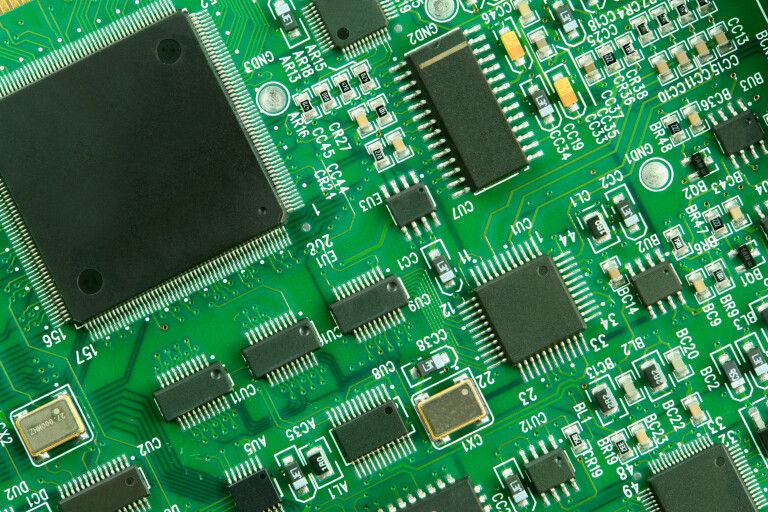

Understanding Basic SMT Components

SMT components, also known as surface mount devices (SMDs), come in various shapes and sizes, each serving a unique function in a circuit. Below, we’ll cover the most common ones—resistors, capacitors, diodes, and transistors—and explain their roles, identification, and typical applications.

1. SMT Resistors

What They Do: Resistors limit the flow of electric current in a circuit, protecting other components from damage or controlling voltage levels. In SMT designs, resistors are tiny rectangular components often marked with a numerical code to indicate their resistance value.

Identification: SMT resistors are usually black or gray and come in standard package sizes like 0402 (1.0mm x 0.5mm), 0603 (1.6mm x 0.8mm), and 0805 (2.0mm x 1.25mm). The resistance value, such as 1kΩ (1000 ohms), is often printed as a three- or four-digit code. For example, "102" means 1kΩ (10 followed by 2 zeros).

Applications: You’ll find SMT resistors in almost every circuit, from simple LED setups to complex microcontrollers, where they help manage current and voltage.

Tip for Beginners: Use a magnifying glass or a microscope to read the tiny codes on SMT resistors. If the value isn’t printed, refer to the circuit schematic or use a multimeter to measure resistance.

2. SMT Capacitors

What They Do: Capacitors store and release electrical energy, smoothing out voltage fluctuations or filtering noise in a circuit. SMT capacitors are essential for power supply stability and signal processing.

Identification: These components are often beige or brown and come in similar package sizes to resistors (e.g., 0603, 0805). Unlike resistors, most SMT capacitors don’t have their capacitance value (e.g., 10μF or 100pF) printed on them. Instead, you’ll need to refer to the PCB documentation or part list.

Applications: SMT capacitors are used in timing circuits, power decoupling (to reduce noise in power lines), and filtering high-frequency signals. For example, a 0.1μF capacitor might be placed near a microcontroller to stabilize its power supply.

Tip for Beginners: Be cautious with polarity for electrolytic SMT capacitors, as they have a positive and negative side. Look for a stripe or marking to identify the negative terminal.

3. SMT Diodes

What They Do: Diodes allow current to flow in one direction only, acting as a one-way valve for electricity. They’re used for rectification (converting AC to DC), protection, and signal modulation.

Identification: SMT diodes are small, often black or gray, and come in packages like SOD-123 or SMA. They usually have a line or band marking the cathode (negative side). Some may have a code like “1N4148” to indicate the part number.

Applications: You’ll see SMT diodes in power supplies for rectification or near sensitive components to prevent reverse voltage damage. For instance, a Schottky diode might be used in a switching power supply due to its fast switching speed (often under 10ns).

Tip for Beginners: Always double-check the orientation of a diode before soldering. Incorrect placement can cause circuit failure.

4. SMT Transistors

What They Do: Transistors act as switches or amplifiers in a circuit, controlling larger currents with smaller input signals. They’re the building blocks of digital and analog electronics.

Identification: SMT transistors often come in packages like SOT-23 (a small, three-pin package) and are marked with a code to identify the part, such as “2N3904” for an NPN transistor. They have three terminals: base, collector, and emitter (for bipolar transistors) or gate, drain, and source (for MOSFETs).

Applications: SMT transistors are used in logic circuits, power management, and signal amplification. For example, a MOSFET transistor might control a motor by switching a 12V supply with a 3.3V signal from a microcontroller.

Tip for Beginners: Check the datasheet for pin configuration, as the layout varies between transistor types. Incorrect connections can damage the component or circuit.

Common Package Sizes for SMT Components

SMT components are categorized by package sizes, which indicate their physical dimensions. Understanding these sizes helps you choose the right components for your design and soldering tools. Here are some common package sizes for surface mount devices:

- 0402: 1.0mm x 0.5mm – Very small, used in compact designs like wearables.

- 0603: 1.6mm x 0.8mm – A popular size for resistors and capacitors in general-purpose circuits.

- 0805: 2.0mm x 1.25mm – Slightly larger, easier to handle for beginners.

- 1206: 3.2mm x 1.6mm – Often used for higher-power components.

Smaller packages save space but are harder to solder by hand. If you’re just starting, opt for larger sizes like 0805 or 1206 for practice.

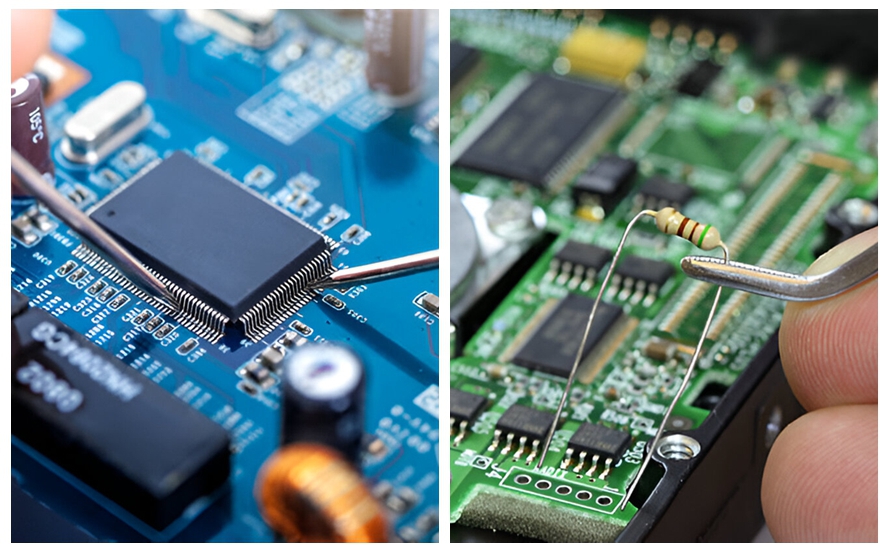

Tips for Working with SMT Components

Handling and soldering surface mount devices can be challenging due to their size, but with the right approach, you’ll get the hang of it. Here are some practical tips:

- Use the Right Tools: Invest in a fine-tip soldering iron (15-25W), tweezers, and a magnifying glass or microscope. A temperature of 300°C is often suitable for soldering SMT components, but check the component datasheet for specifics.

- Practice Soldering: Start with larger components (e.g., 1206 size) before moving to smaller ones. Use flux to improve solder flow and prevent cold joints.

- Organize Components: SMT parts are tiny and easy to lose. Use a component tray or labeled tape strips to keep them sorted.

- Read Datasheets: Always consult the datasheet for component specifications, such as voltage ratings (e.g., a capacitor rated for 16V) or current limits (e.g., a diode handling 1A).

- Double-Check Polarity: For components like diodes and capacitors, ensure correct orientation before soldering to avoid circuit issues.

Challenges of Working with SMT Components

While SMT offers many benefits, it also comes with challenges, especially for beginners:

- Small Size: Components as small as 0402 can be difficult to handle without steady hands or proper tools.

- Soldering Precision: Unlike through-hole components, SMT soldering requires accuracy to avoid bridging pads or damaging parts.

- Identification Issues: Many SMT components lack clear markings, making it hard to identify values without documentation.

To overcome these challenges, take your time, practice on scrap boards, and consider using automated assembly services for complex designs.

Applications of SMT Components in Modern Electronics

SMT components are everywhere in today’s technology. Here are a few examples of where they’re used:

- Consumer Electronics: Smartphones and tablets rely on SMT for compact, high-performance circuits.

- Automotive Systems: Engine control units (ECUs) use SMT components for reliability in harsh environments.

- Medical Devices: Wearable health monitors use tiny SMT components to save space and power.

By learning SMT, you’re preparing yourself to work on cutting-edge projects in these fields.

Conclusion: Start Your SMT Journey Today

Getting started with Surface Mount Technology doesn’t have to be intimidating. By understanding the basic SMT components—resistors, capacitors, diodes, and transistors—you’ve taken the first step toward mastering this essential skill. These surface mount devices are the foundation of modern electronics, enabling smaller, faster, and more efficient designs.

Begin with larger package sizes, practice your soldering skills, and always refer to datasheets for accurate information. As you gain confidence, you’ll be able to tackle more complex projects and bring your ideas to life on a PCB. At ALLPCB, we’re here to support your journey with resources and services tailored to your electronics needs. Dive into the world of SMT today, and watch your designs come to life!

ALLPCB

ALLPCB