The terms air-to-open and air-to-close describe the overall behavior of a control valve assembly. As diaphragm air pressure increases, a valve that opens progressively is called air-to-open; one that closes progressively is called air-to-close. Without a signal, an air-to-open valve remains closed, while an air-to-close valve remains fully open.

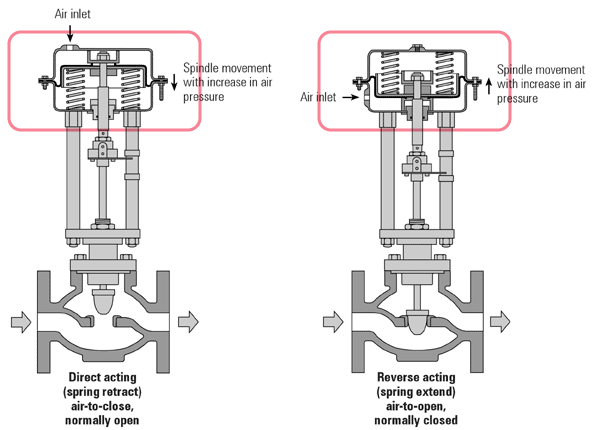

Direct-acting and reverse-acting refer to the pneumatic diaphragm actuator itself. When air is applied to the top of the diaphragm and the stem moves downward, the actuator is direct-acting. When air is applied to the bottom of the diaphragm and the stem moves upward, the actuator is reverse-acting.

Flow-to-open and flow-to-close describe the process fluid direction relative to the valve. If the fluid through the throttling orifice flows in the direction that tends to open the valve, the valve is flow-to-open. If the flow tends to push the valve toward the closed position, it is flow-to-close.

1. Forms of Pneumatic Actuator Action

- Actuator direct and reverse action. When the actuator input air pressure increases and the stem moves downward, the actuator is direct-acting. If increasing input pressure causes the stem to move upward, the actuator is reverse-acting.

- Valve plug orientation. The valve plug can be installed in direct or reverse orientation. If the plug moving downward reduces the flow area, the valve is installed in direct orientation. If the plug moving downward increases the flow area, it is reverse orientation.

- Actuator function as air-to-open or air-to-close. An actuator whose output causes the valve to open as signal pressure increases is air-to-open. Conversely, if increasing signal pressure causes the valve to close, it is air-to-close.

For small-diameter control valves, air-to-open or air-to-close behavior is usually achieved by changing the actuator action (direct or reverse). For large-diameter valves, the valve plug orientation (direct or reverse installation) is typically changed to achieve the desired air-to-open or air-to-close behavior.

2. Positioner

The positioner is used together with a pneumatic diaphragm actuator.

- Direct-acting positioner: when the input signal increases, the output pressure to the diaphragm increases.

- Reverse-acting positioner: when the input signal increases, the output pressure to the diaphragm decreases.

Combining actuator and positioner actions determines the overall action: a direct-acting actuator with a direct-acting positioner gives direct action; a direct-acting actuator with a reverse-acting positioner gives reverse action; a reverse-acting actuator with a direct-acting positioner gives reverse action; a reverse-acting actuator with a reverse-acting positioner gives direct action.

3. FC (Fail Close) and FO (Fail Open)

The choice between air-to-open and air-to-close is made from a safety perspective for the process. When the air supply is lost, it must be determined whether a closed or open valve position is safer.

Air-to-open means the valve is fully closed when air is lost; the valve opens only when air is supplied. Without a signal the valve is closed; as the input signal increases, the valve opens progressively until it is fully open at maximum signal. Because the valve closes on loss of air, air-to-open valves are sometimes called fail-close (FC).

Air-to-close behaves oppositely. As air pressure increases the valve moves toward closed; when air pressure decreases or is absent the valve moves toward open until fully open. Because the valve opens on loss of air, this type is sometimes called fail-open (FO).

Pneumatic valves can be used for on/off isolation, interlock actions, or throttling control. They offer relatively fast response and, with different accessories, can implement various control strategies.

Air-to-open valves increase flow area as signal pressure increases; air-to-close valves decrease flow area as signal pressure increases.

ALLPCB

ALLPCB