1. Breaker usage categories

Breakers are classified as CAT A and CAT B. CAT A molded-case breakers are typically used as incoming or branch breakers in distribution panels; most molded-case breakers are marked CAT A. CAT B breakers are mainly used as low-voltage incoming main switches; many air circuit breakers fall into CAT B and are usually installed in distribution rooms or main switchgear.

2. Residual current protection: RCBO, RCCB, RCD

RCBO (Residual Current operated Circuit-breaker with Integral Overcurrent protection) is a residual-current operated device that can also provide overload and/or short-circuit protection, such as an integrated residual-current circuit breaker.

RCCB (Residual Current operated Circuit-breaker) is a residual-current device that does not provide overload or short-circuit protection, commonly referred to as a residual-current switch.

RCD (Residual Current Device) refers to residual-current operated protective devices whose detection, decision, and disconnection functions are independent of the supply voltage, for example residual-current operated accessories.

3. What do 10/350 and 8/20 mean for surge protectors?

Both parameters describe lightning current waveform shapes, expressed as time versus current curves. The 10/350 us waveform is typical for a lightning stroke directly striking ground or power conductors, representing direct lightning current and usually called a direct strike waveform.

The 8/20 us waveform represents an induced electromagnetic pulse overvoltage caused by a lightning strike to ground; it describes the current curve when the induced overvoltage breaks down or damages equipment and is commonly called an induced lightning waveform.

Surge protector current ratings (expressed in kA) are specified with reference to their corresponding waveform type.

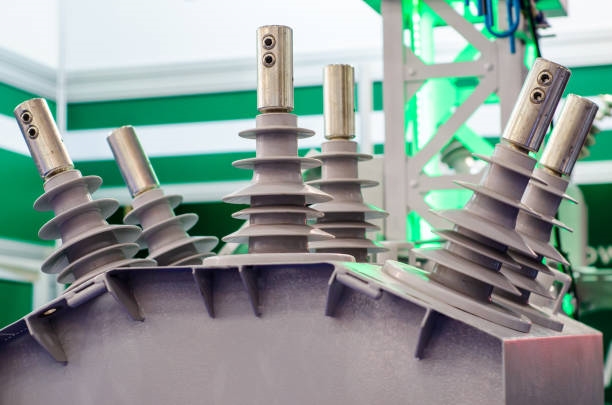

4. IP protection ratings for high-voltage switchgear

IP ratings indicate the enclosure's protection against access to hazardous parts and the ingress of solid foreign objects. Common designations are:

- IP1X: Protects against solid objects greater than 50 mm in diameter; prevents access to large parts of the body to live parts inside the cabinet.

- IP2X: Protects against solid objects greater than 12.5 mm in diameter; prevents finger access to live parts inside the cabinet.

- IP3X: Protects against solid objects greater than 2.5 mm in diameter; prevents access by tools or wires to live parts inside the cabinet.

- IP4X: Protects against solid objects greater than 1 mm in diameter; prevents access by small tools or wires to live parts inside the cabinet.

- IP5X: Dust-protected; limited ingress of dust is permitted but it does not interfere with satisfactory operation, and access to live parts is fully protected.

- IP6X: Dust-tight; no ingress of dust and full protection against access to live parts.

Understanding these ratings helps select an appropriate level of enclosure protection for switchgear applications.

5. Transformer hum during operation: causes and mitigation

Transformer noise, if left unaddressed, can eventually lead to operational issues. The noise mainly originates from magnetostriction in the core laminations (and electromagnetic forces where air gaps are present). Other sources include electromagnetic forces on windings and vibration transmitted through transformer accessories, including resonant conditions.

On-site noise troubleshooting should first identify the noise source. In dry-type transformers, noise often comes from resonance between the core and the enclosure; in some cases, loose fasteners can generate noise. Inspect and correctly tighten all fasteners and components, including rods, shims, base bolts, enclosure connection bolts, and fan components. Remove any foreign objects from fan housings and check for rotor imbalance. For resonance-related noise, secure the resonant parts or add damping elements such as rubber pads to reduce or eliminate the noise.

ALLPCB

ALLPCB