In the fast-paced world of electronics manufacturing, ensuring the reliability of printed circuit boards (PCBs) is essential. One of the most critical aspects of this process is inspecting Ball Grid Array (BGA) and Micro-BGA components for hidden defects. X-ray inspection stands out as a powerful tool for detecting issues like solder ball defects that are invisible to the naked eye. This blog dives deep into why X-ray inspection is a vital quality control step for BGA and Micro-BGA assemblies, exploring its advantages and how it helps maintain high standards in PCB production.

If you're looking for a quick answer, X-ray inspection is critical for BGA and Micro-BGA components because it reveals hidden defects under the package, such as voids, cracks, or poor solder connections, ensuring the reliability of high-density electronics. Now, let’s explore this topic in detail to understand the importance of BGA inspection, Micro-BGA inspection, solder ball defects, hidden defects, and the specific advantages of X-ray technology in quality control.

What Are BGA and Micro-BGA Components?

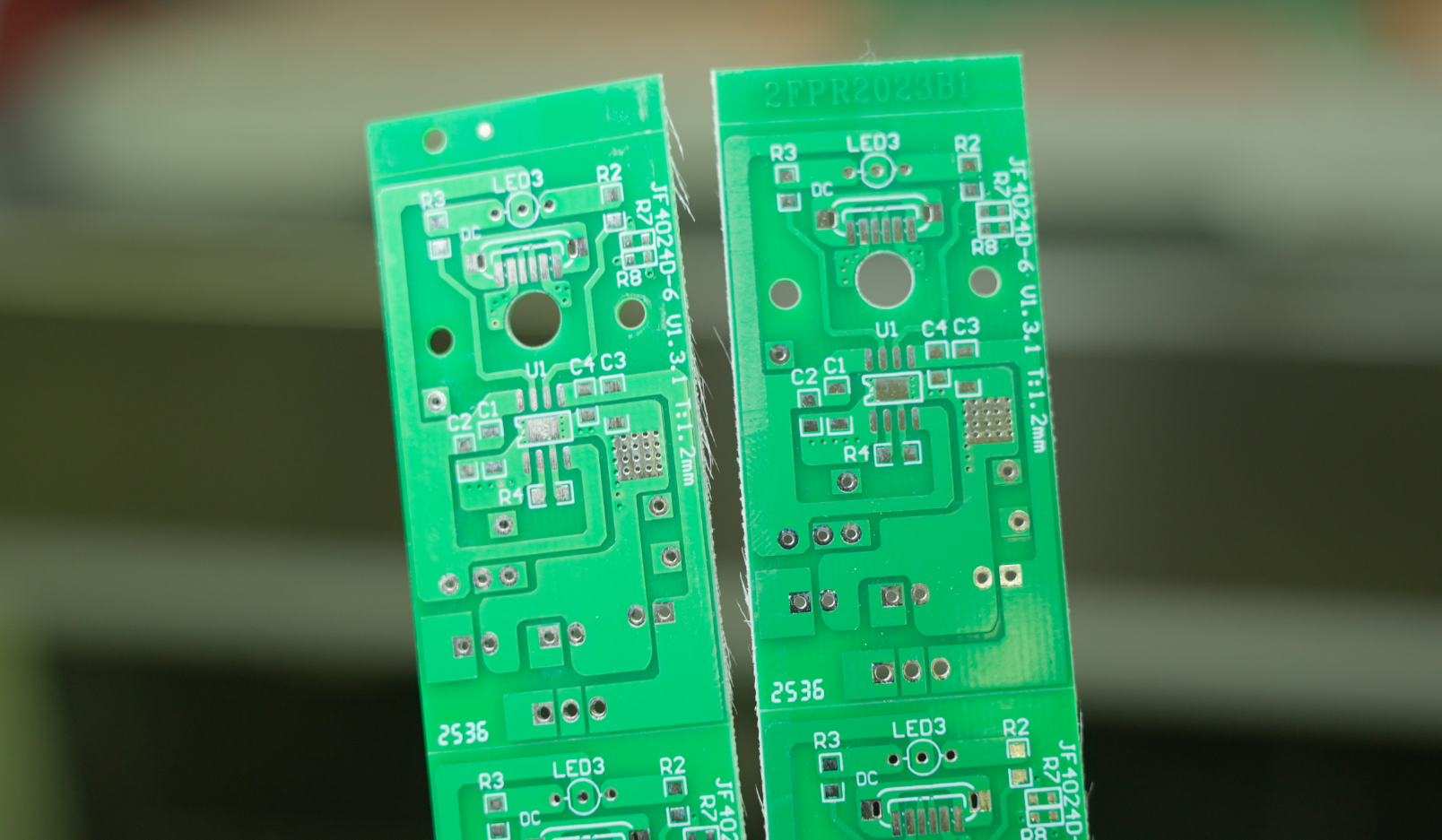

Ball Grid Array (BGA) is a surface-mount packaging technology widely used in modern electronics. Unlike traditional components with visible leads, BGA packages have an array of tiny solder balls on the underside that connect the component to the PCB. This design allows for a high number of connections—often exceeding 200 solder balls—making it ideal for complex, high-density devices like microprocessors and graphics chips.

Micro-BGA is a smaller version of BGA, designed for even more compact applications. With solder balls often less than 0.3 mm in diameter and pitches as tight as 0.4 mm, Micro-BGA components are common in smartphones, wearables, and other miniature devices. While these technologies enable incredible performance in small spaces, they also present unique challenges in inspection due to their hidden connections.

Why Is Inspection Crucial for BGA and Micro-BGA?

The solder balls in BGA and Micro-BGA components are hidden beneath the package, making visual inspection impossible. Defects in these connections can lead to device failure, reduced performance, or safety risks, especially in critical industries like aerospace, medical, and automotive. Common issues include:

- Solder Ball Defects: These include voids (air bubbles within the solder), cracks, or insufficient solder volume, which can weaken the connection.

- Hidden Defects: Misalignments, bridging (solder connecting adjacent balls), or incomplete reflow can occur without any visible signs on the surface.

- Head-in-Pillow Defects: A specific issue where the solder ball and paste fail to fully merge, creating a weak joint that looks fine externally but fails under stress.

Without proper inspection, these issues can go undetected until the device fails in the field, leading to costly recalls or repairs. This is where advanced inspection techniques, particularly X-ray inspection, become indispensable for ensuring quality.

The Challenges of BGA and Micro-BGA Inspection

Inspecting BGA and Micro-BGA components is no easy task. Traditional methods like optical or visual inspection fall short because they cannot see beneath the component. Even advanced magnification tools have limitations due to the risk of electrostatic discharge (ESD) damage or the inability to access hidden areas. Additionally, the small size of Micro-BGA solder balls and tight spacing make it difficult to detect defects without specialized equipment.

For instance, a typical BGA might have a pitch (distance between solder balls) of 0.8 mm, while a Micro-BGA could go down to 0.4 mm. At these scales, even a tiny void or misalignment—sometimes as small as 0.1 mm—can cause a failure. This level of precision demands a non-destructive testing method that can penetrate the component and reveal internal structures, which is exactly what X-ray inspection offers.

What Is X-ray Inspection and How Does It Work?

X-ray inspection is a non-destructive testing method that uses X-ray radiation to create detailed images of a PCB’s internal structures. The technology works by passing X-rays through the board and components, capturing differences in density to produce a grayscale image. Dense materials like solder appear darker, while less dense areas like voids or air gaps appear lighter, making defects easy to spot.

In the context of BGA and Micro-BGA inspection, X-ray systems can reveal the condition of solder balls hidden beneath the package. They can detect issues like voids, cracks, misalignments, and bridging with high accuracy. Modern X-ray equipment often includes 2D and 3D imaging capabilities, allowing for a comprehensive view of the solder joints from multiple angles.

For example, a 2D X-ray image might show a solder ball with a void occupying 20% of its volume, indicating a potential weak point. A 3D computed tomography (CT) scan can go further, providing a cross-sectional view to pinpoint the exact location of the defect within the ball. This level of detail is critical for high-reliability applications where even small flaws can lead to failure.

Key Advantages of X-ray Inspection for BGA and Micro-BGA

X-ray inspection offers several unique benefits that make it a cornerstone of quality control in PCB manufacturing. Below are some of the most significant advantages, particularly when it comes to BGA inspection and Micro-BGA inspection.

1. Detection of Hidden Defects

The primary advantage of X-ray inspection is its ability to reveal hidden defects beneath BGA and Micro-BGA packages. Issues like solder ball defects, voids, and incomplete joints are invisible to optical methods but can be clearly identified using X-ray imaging. This ensures that even the smallest flaws—down to a few micrometers—are caught before they cause problems.

2. Non-Destructive Testing

Unlike destructive testing methods that require cutting or breaking the PCB, X-ray inspection is completely non-destructive. This means you can inspect every board in a batch without damaging any, maintaining production efficiency while ensuring quality. For high-value assemblies, this is a game-changer.

3. High Precision for Small Components

With Micro-BGA components featuring solder balls as small as 0.2 mm, precision is everything. X-ray systems can achieve resolutions in the micrometer range, making them ideal for detecting tiny defects in tight spaces. This is especially important as electronics continue to shrink in size.

4. Comprehensive Analysis with 3D Imaging

Advanced X-ray systems offer 3D imaging and CT scanning, providing a detailed view of solder joints from all angles. This capability is particularly useful for complex BGA assemblies with multiple layers or stacked components, where 2D images might miss critical defects.

5. Improved Yield and Cost Savings

By catching defects early in the manufacturing process, X-ray inspection helps reduce the risk of field failures and costly rework. For example, identifying a batch of boards with 10% voiding in solder balls during production allows for immediate corrective action, saving thousands of dollars in potential recalls.

Common Solder Ball Defects Detected by X-ray Inspection

Solder ball defects are a leading cause of BGA and Micro-BGA failures. X-ray inspection excels at identifying these issues, allowing manufacturers to address them before they impact performance. Here are some of the most common defects detected:

- Voids: Air bubbles or gaps within the solder ball, often caused by trapped flux or improper reflow. Voids larger than 25% of the solder ball volume can significantly weaken the joint.

- Cracks: Fractures in the solder ball due to thermal stress or mechanical shock. These can lead to intermittent connections or complete failure.

- Bridging: Unintended connections between adjacent solder balls, often caused by excess solder or misalignment, leading to short circuits.

- Insufficient Solder: Solder balls that are too small or poorly formed, resulting in weak or unreliable connections.

- Misalignment: Solder balls that are not properly aligned with the PCB pads, reducing contact area and risking open circuits.

Each of these defects can be clearly visualized using X-ray inspection, providing manufacturers with the data needed to refine their processes and improve quality.

How X-ray Inspection Fits Into the Quality Control Process

X-ray inspection is typically integrated into the quality control workflow during or after the soldering process. Here’s how it fits into the broader manufacturing process:

- Post-Reflow Inspection: After BGA and Micro-BGA components are soldered to the PCB, X-ray inspection is used to check the integrity of the solder joints. This is the most common stage for detecting defects like voids or bridging.

- Sample Testing: For large production runs, X-ray inspection may be applied to a sample of boards to verify process consistency, reducing inspection time while maintaining quality.

- Failure Analysis: If a board fails during functional testing, X-ray inspection can be used to identify the root cause, such as a cracked solder ball or misalignment.

- Process Optimization: Data from X-ray inspections can be used to fine-tune soldering parameters, such as reflow temperature profiles, to minimize defects in future runs.

By incorporating X-ray inspection at these stages, manufacturers can achieve higher reliability and consistency in their PCB assemblies.

Choosing the Right X-ray Inspection System

Not all X-ray inspection systems are created equal. When selecting equipment for BGA and Micro-BGA inspection, consider the following factors:

- Resolution: Look for systems with high resolution (below 5 micrometers) to detect tiny defects in Micro-BGA components.

- Imaging Capabilities: Opt for systems with both 2D and 3D imaging to provide a complete view of solder joints.

- Throughput: For high-volume production, choose a system with fast scanning speeds to avoid bottlenecks.

- Software Features: Advanced analysis software can automatically detect and measure defects, improving efficiency and reducing human error.

Investing in the right X-ray system ensures that hidden defects are caught early, protecting the quality of your final product.

Conclusion: The Importance of X-ray Inspection in PCB Manufacturing

In the world of high-density electronics, BGA and Micro-BGA components are essential for creating powerful, compact devices. However, their hidden solder connections pose significant challenges for quality control. X-ray inspection has emerged as a critical tool for detecting solder ball defects and other hidden issues, ensuring the reliability and performance of PCBs.

With its ability to provide detailed, non-destructive imaging, X-ray technology offers unmatched advantages for BGA inspection and Micro-BGA inspection. From identifying tiny voids to preventing costly field failures, it plays a vital role in modern manufacturing. By integrating X-ray inspection into the quality control process, manufacturers can achieve higher yields, lower costs, and greater confidence in their products.

At ALLPCB, we understand the importance of precision and reliability in PCB assembly. Our commitment to advanced inspection techniques like X-ray ensures that every board meets the highest standards of quality. Whether you're working on consumer electronics or critical applications, trust us to deliver flawless results with every project.

ALLPCB

ALLPCB