If you're exploring options for your next printed circuit board (PCB) design and wondering about the benefits and drawbacks of a white solder mask, you're in the right place. A white solder mask offers unique advantages like enhanced reflectivity for LED lighting and improved aesthetics, but it also comes with challenges such as higher cost and potential durability issues. In this comprehensive guide, we'll dive deep into the pros and cons of using a white solder mask, explore its best use cases, and help you decide if it's the right choice for your project. Whether you're focused on PCB aesthetics, solder mask contrast, or specific applications like PCB LED lighting, we've got you covered with practical insights and actionable advice.

What Is a White Solder Mask?

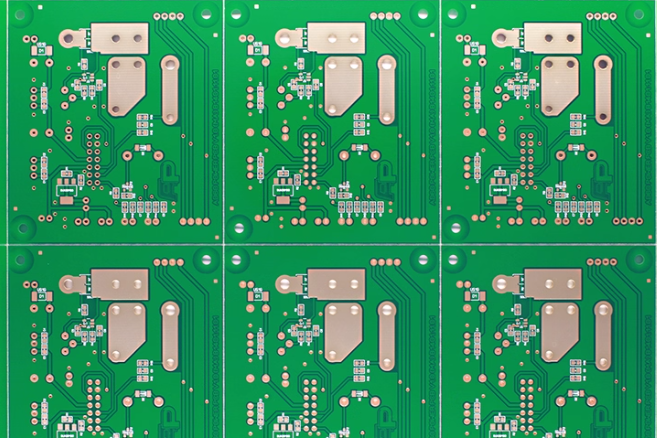

A solder mask is a protective layer applied to a PCB to prevent solder from bridging between conductive traces and to shield the board from environmental damage. While the traditional green solder mask is the most common, other colors like blue, red, black, and white are also available. A white solder mask, as the name suggests, is a white-colored coating that not only serves the functional purpose of protection but also provides distinct visual and performance benefits.

Unlike darker colors, a white PCB stands out due to its clean, modern look and its ability to reflect light. This makes it a popular choice in specific industries where appearance and light management are critical. But before we get into the details of its applications, let’s break down the key advantages and disadvantages of opting for a white solder mask in your PCB design.

Pros of Using a White Solder Mask

Choosing a white solder mask for your PCB can offer several benefits, especially in specific applications. Here are the main advantages that make it a compelling option for many engineers and designers.

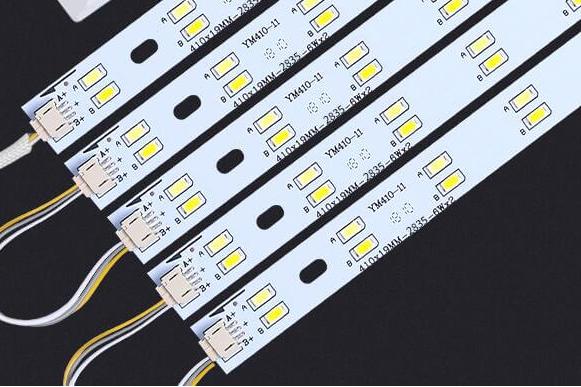

1. Enhanced Reflectivity for LED Lighting

One of the standout benefits of a white solder mask is its high reflectivity, which is particularly valuable in PCB LED lighting applications. When used in LED boards, the white surface reflects more light compared to darker solder masks like green or black. This can improve the overall brightness and efficiency of the lighting system by up to 10-15%, depending on the design and materials used. For instance, in automotive lighting or commercial LED fixtures, this increased reflectivity can help achieve a cleaner, brighter white light output without the yellowish tint that darker masks might cause due to light absorption.

2. Improved Aesthetics for Modern Designs

PCB aesthetics matter more than ever, especially in consumer electronics where the look of a product can influence buyer decisions. A white PCB offers a sleek, professional appearance that stands out from the traditional green boards. This modern look is often preferred in devices like smart home gadgets, wearable tech, and high-end audio equipment, where the internal components might be visible through transparent casings or during marketing displays.

3. Better Solder Mask Contrast for Inspection

Solder mask contrast refers to how well the markings, traces, and components stand out against the background color of the PCB. With a white solder mask, silkscreen markings (usually in black) are much easier to read compared to darker masks. This improved visibility can speed up manual inspections and troubleshooting by as much as 20%, reducing errors during assembly and quality control processes. This is especially useful in complex designs with dense component layouts.

4. Thermal Management Benefits

While not as significant as reflectivity, a white solder mask can contribute to better thermal management in some scenarios. Its lighter color reflects heat rather than absorbing it, which can help keep the PCB cooler under high-power conditions. This is particularly relevant in LED applications where heat dissipation is a constant concern, potentially extending the lifespan of components by reducing thermal stress.

Cons of Using a White Solder Mask

While a white solder mask has distinct advantages, it’s not without its challenges. Understanding these drawbacks will help you make an informed decision for your PCB design.

1. Higher Cost Compared to Standard Colors

One of the primary downsides of a white solder mask is its cost. Due to the specialized materials and manufacturing processes required, white solder masks can be 10-30% more expensive than standard green masks. This price difference can add up quickly in large-scale production runs, making it less economical for budget-conscious projects where aesthetics or reflectivity are not critical.

2. Potential Durability Issues

White solder masks are often less resistant to discoloration and wear compared to darker colors. Over time, exposure to UV light, heat, and environmental factors can cause the white coating to yellow or fade, affecting both the appearance and performance of the PCB. This is a notable concern in outdoor applications or high-temperature environments where the board is under constant stress.

3. Limited Availability and Longer Lead Times

Not all PCB manufacturers offer white solder masks as a standard option, which can lead to longer lead times for production. Additionally, the specialized nature of the material might require additional processing steps, further delaying delivery. If time-to-market is a critical factor for your project, this could pose a significant challenge.

4. Challenges with Cleaning and Maintenance

A white PCB shows dirt, dust, and smudges more easily than darker colors. During assembly or in end-use environments, maintaining the clean look of a white solder mask can be difficult. This is particularly problematic in industrial settings where boards are exposed to contaminants, as frequent cleaning might risk damaging the mask or underlying traces.

Best Use Cases for White Solder Masks

Given the unique pros and cons of white solder masks, they are best suited for specific applications where their benefits outweigh the drawbacks. Below are the most common use cases where a white PCB truly shines.

1. PCB LED Lighting Applications

As mentioned earlier, white solder masks are ideal for LED lighting due to their high reflectivity. They are widely used in automotive headlights, street lighting, and residential LED fixtures to maximize light output and maintain color accuracy. For example, in a typical LED strip design, a white mask can help reflect up to 90% of the emitted light, compared to only 70-80% with a green mask, based on industry studies. This makes them a go-to choice for engineers prioritizing efficiency and brightness.

2. Consumer Electronics with Visible PCBs

In devices where the PCB is part of the visual design—such as gaming consoles, smart speakers, or fitness trackers with transparent casings—a white solder mask adds a premium, high-tech feel. The clean look aligns with modern design trends and can enhance the perceived value of the product in the eyes of consumers.

3. Prototyping and Design Validation

During the prototyping phase, the high solder mask contrast of a white PCB makes it easier to spot errors in component placement or trace routing. This can be invaluable for engineers working on intricate designs, as it reduces the likelihood of overlooking small defects during visual inspections.

4. High-End or Custom Electronics

For boutique electronics or custom projects where branding and uniqueness are key, a white solder mask can set a product apart. It’s often used in limited-edition devices or specialized equipment to create a distinctive look that reflects attention to detail and quality craftsmanship.

Comparing White Solder Mask to Other Colors

To fully understand the value of a white solder mask, it’s helpful to compare it to other common colors in terms of functionality and aesthetics. Here’s a quick overview:

- Green Solder Mask: The industry standard due to its low cost and high durability. However, it offers poor reflectivity and less appealing aesthetics compared to white.

- Black Solder Mask: Often used for high-contrast designs and to hide traces in sensitive applications. It absorbs light and heat, making it unsuitable for LED lighting.

- Blue Solder Mask: A middle ground for aesthetics, offering a modern look with decent durability. However, it lacks the reflectivity of white for lighting applications.

- Red Solder Mask: Eye-catching and used for branding, but it can make silkscreen markings harder to read and offers no specific performance benefits over white.

In summary, while other colors have their place, a white solder mask excels in applications where light reflection and visual appeal are priorities.

Tips for Implementing a White Solder Mask in Your Design

If you’ve decided that a white solder mask is the right fit for your project, here are some practical tips to ensure success:

- Choose High-Quality Materials: Opt for a solder mask with UV resistance to minimize yellowing over time. Discuss options with your PCB supplier to ensure long-term durability.

- Test Reflectivity in Prototypes: For LED applications, prototype your design with a white mask and measure light output to confirm it meets your expectations. Use a lux meter to quantify brightness improvements.

- Plan for Maintenance: If the PCB will be exposed to dirt or harsh conditions, consider additional protective coatings or enclosures to preserve the white finish.

- Account for Cost: Budget for the higher cost of a white solder mask, especially if you’re scaling up production. Weigh the added expense against the benefits for your specific use case.

Conclusion: Is a White Solder Mask Right for Your Project?

A white solder mask offers a unique blend of functionality and style, making it an excellent choice for specific PCB designs. Its advantages, such as enhanced reflectivity for PCB LED lighting, superior solder mask contrast for inspections, and modern PCB aesthetics, make it ideal for applications like LED fixtures and consumer electronics. However, the higher cost, potential durability issues, and maintenance challenges mean it’s not a one-size-fits-all solution.

When deciding whether to use a white solder mask, consider your project’s priorities. If brightness, visibility, or a premium look are critical, the benefits likely outweigh the drawbacks. On the other hand, for cost-sensitive or rugged applications, a more traditional color might be a better fit. By weighing these factors and following the tips provided, you can make an informed choice that aligns with your technical and design goals.

At ALLPCB, we’re committed to helping you bring your PCB designs to life with the right materials and finishes. Whether you’re exploring a white PCB for its aesthetic appeal or functional benefits, our team is here to support you every step of the way with high-quality manufacturing solutions tailored to your needs.