When charging a phone, have you wondered how chargers precisely control current to prevent battery damage? During fast charging of electric vehicles, what ensures charging efficiency and safety? The answer lies with an "invisible guardian" — the current sensor. This technical device is already present throughout daily life. Here is a 3-minute look at how it works.

Fundamentals: Difference Between Current Sensors and Ammeters

Many people confuse current sensors with ammeters, but their core functions differ significantly. An ammeter only displays the current value, while a current sensor performs "sensing + conversion" — it accurately detects changes in the current flowing through a conductor and converts them into signals such as voltage or current that control systems can process. These signals provide data for control-system outputs.

Academic literature shows that current sensors are used across automotive electronics, industrial control, medical equipment, and consumer electronics. From a home's variable-speed air conditioner to precision instruments in hospitals, from photovoltaic power plants to urban rail power networks, current sensors play a monitoring role in many systems.

Principle: Magnetic-Field Based Current Detection Methods

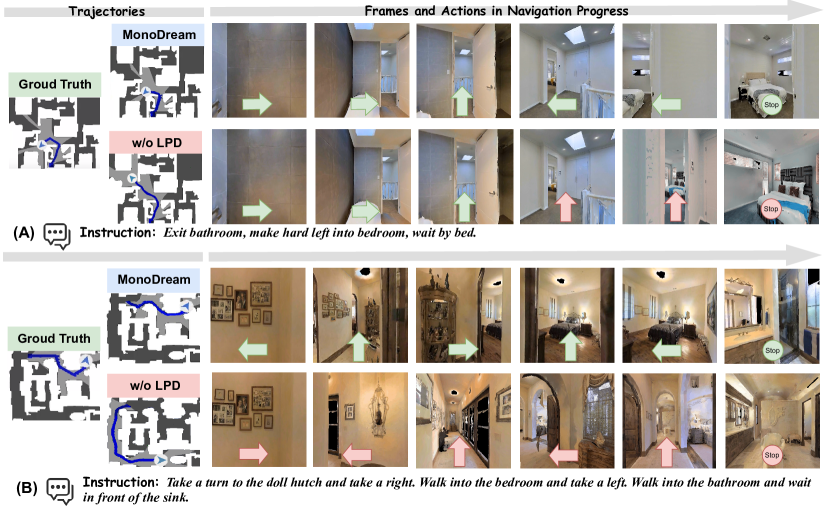

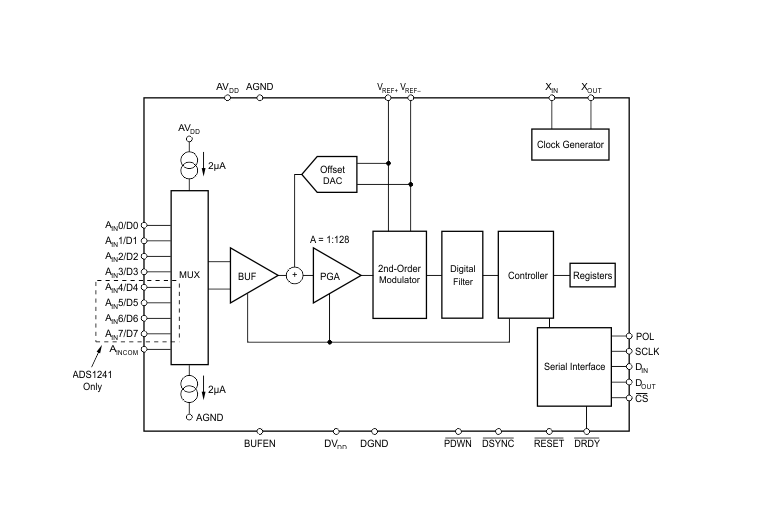

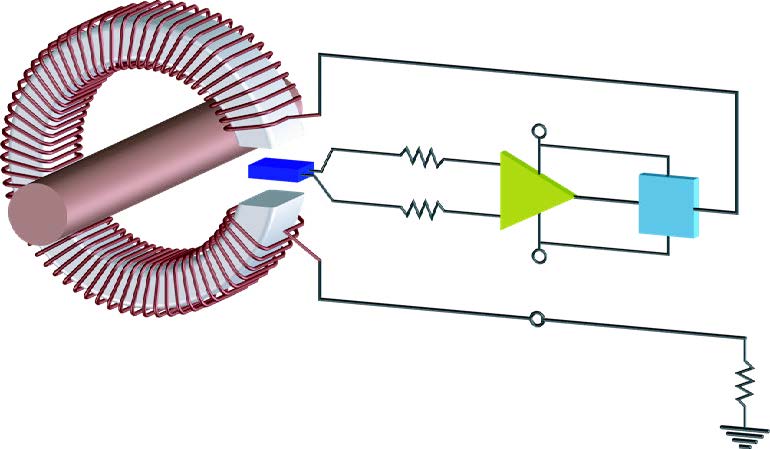

Current sensors detect the otherwise invisible current by exploiting the physics principle that a current-carrying conductor generates a magnetic field, and the field strength is directly related to the current magnitude. By measuring this magnetic field, the sensor can infer the current. Main sensor types, classified by detection technique, include:

- Hall-effect sensors: a versatile baseline. These use Hall elements to convert magnetic-field strength into a voltage signal. Their advantages include small size and relatively low cost, and they can measure both AC and DC currents. They are widely used in phone chargers, household appliances, and other consumer scenarios. Note that temperature can introduce small measurement errors, so product-level calibration is necessary.

- Current transformers: standard for high-voltage scenarios. As a traditional current-detection technology, current transformers provide strong electrical isolation and enable safe measurement in high-voltage, high-current environments, making them fundamental in power grids and industrial motor systems. Their limitations include suitability only for AC measurement and relatively larger size.

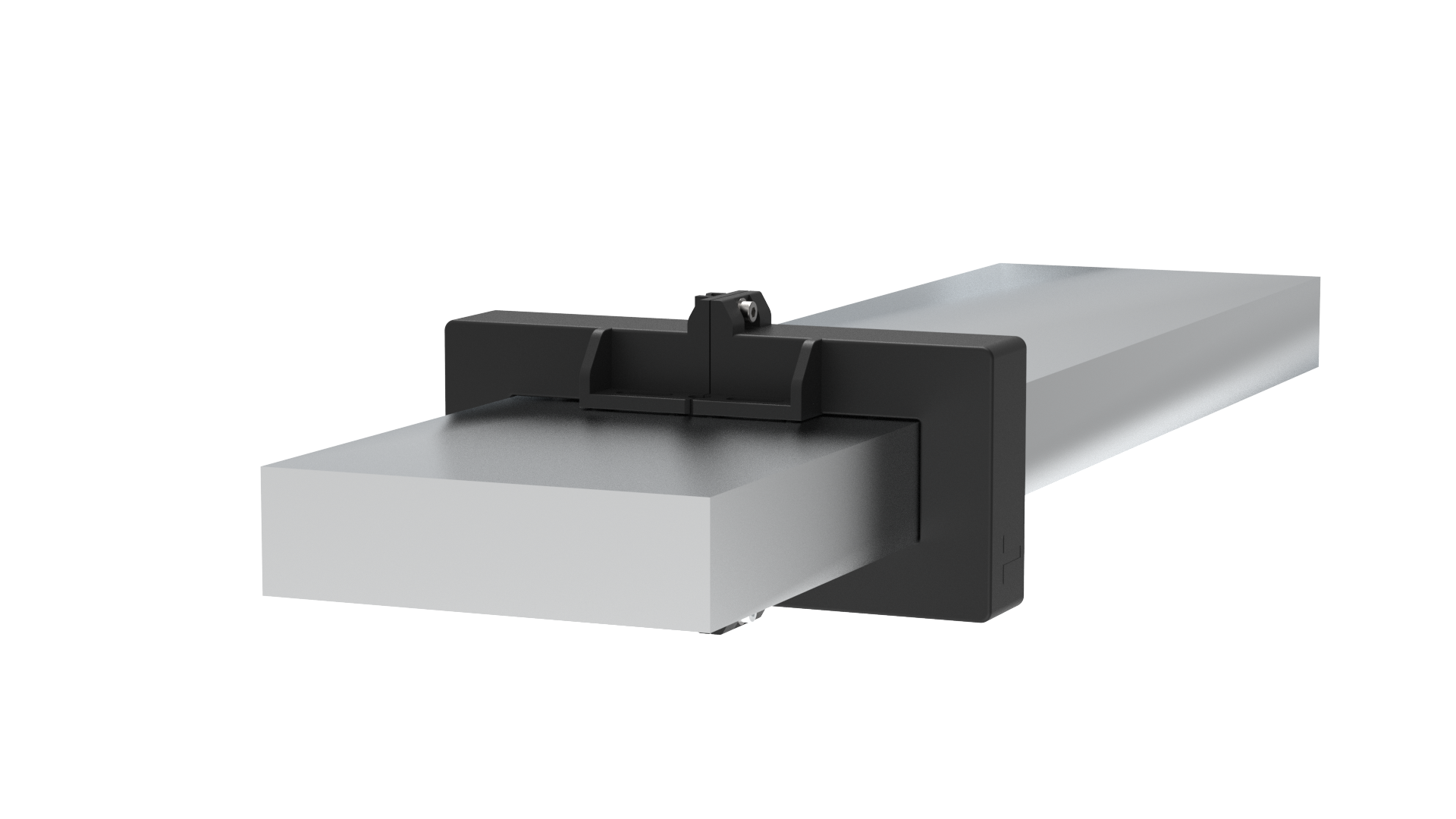

- Magnetoresistive sensors: miniaturized modern option. Newer sensors based on tunnel magnetoresistance (TMR) achieve non-contact measurement with a miniaturized form factor and support live installation, meeting trends toward intelligence and miniaturization in power systems.

Applications: Key Use Cases for Current Sensors

The technical characteristics of current sensors make them responsible for critical detection tasks in many fields, directly affecting equipment safety and operational efficiency. Key application scenarios include:

- Electric vehicles: charging safety and state-of-charge measurement. During fast charging, current sensors monitor the charging-circuit current in real time. If an overload is detected, the sensor signals the control system to open the circuit, preventing battery overcharge and related safety incidents. Accurate tracking of current during charge and discharge also supports state-of-charge (SOC) calculations, improving range display accuracy.

- Photovoltaic power plants: efficiency monitoring. When solar panels generate power, current sensors monitor the current of each string. If a panel is shaded and its current deviates, the system can respond to minimize the impact and maintain overall plant efficiency.

- Power systems: stable monitoring under extreme conditions. Modern optical current sensors exhibit strong environmental adaptability. In a wide temperature range, for example from -40°C to 40°C, some sensors maintain measurement error below 0.2%, exceeding typical industry requirements. This stability ensures reliable grid monitoring across different climates and supports grid reliability.

Conclusion: Technical Value and Development Significance

In essence, current sensors are core components that make current measurable and controllable, providing the basic data required for precise control of electrical equipment. The evolution from traditional current transformers to magnetoresistive sensors and the expanded applications from industrial production to consumer devices reflect the broader shift toward finer, more intelligent power-system control. In both daily electricity use and industrial production, accurate current measurement directly safeguards electrical safety and equipment efficiency.

ALLPCB

ALLPCB