In the world of electronics manufacturing, thermal profiling is a critical process for ensuring the quality and reliability of printed circuit boards (PCBs) during soldering. But why is calibration so important in thermal profiling? Simply put, calibration ensures that the temperature data collected during the soldering process is accurate, helping manufacturers avoid defects, maintain consistent performance, and meet industry standards like those for lead-free soldering. Without proper calibration, issues like thermocouple wear and drift can lead to inaccurate data trends, compromising the entire production process.

In this blog, we'll dive deep into the significance of calibration in thermal profiling, exploring how it impacts thermocouples, ensures consistent performance, and supports modern soldering techniques. Whether you're an engineer or a manufacturer, understanding these concepts can help you optimize your PCB assembly process.

What is Thermal Profiling and Why Does It Matter?

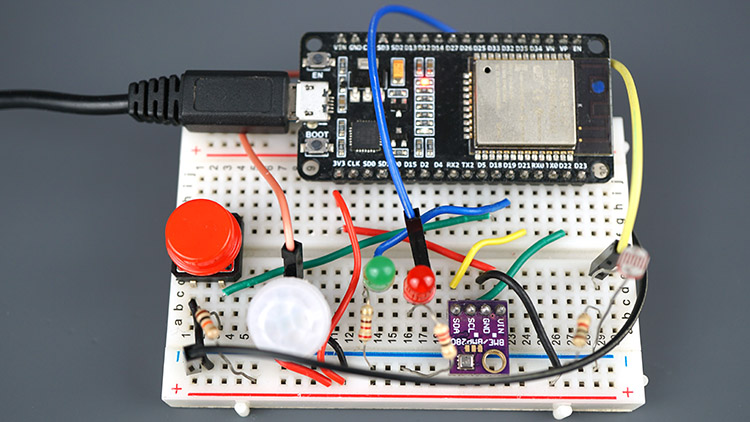

Thermal profiling is the process of measuring and recording the temperature changes a PCB undergoes during soldering, especially in reflow ovens used for surface-mount technology (SMT). This data helps manufacturers ensure that the soldering process meets the specific requirements for forming strong, reliable solder joints without damaging components.

The importance of thermal profiling lies in its ability to prevent common issues like insufficient soldering, overheating, or component damage. For instance, if the peak temperature during reflow soldering is too low, the solder may not melt properly, leading to weak joints. On the other hand, temperatures that are too high can damage sensitive components or cause delamination of the PCB. Accurate thermal profiling helps strike the right balance, ensuring both quality and efficiency.

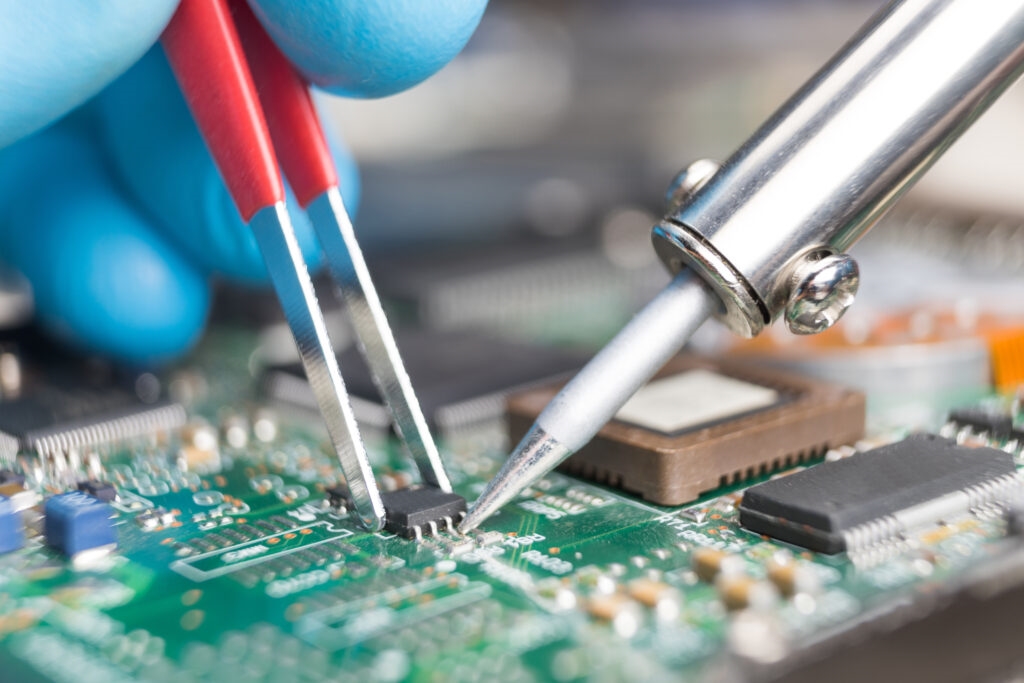

The Role of Thermocouples in Thermal Profiling

Thermocouples are the primary sensors used to measure temperature during thermal profiling. These devices consist of two different metal wires joined at one end, generating a voltage based on the temperature difference between the junction and the other end. This voltage is then converted into a temperature reading.

In a typical reflow soldering setup, multiple thermocouples are attached to different points on a PCB to capture temperature data across the board. This data is used to create a thermal profile, which maps out how the board heats up and cools down during the soldering process. However, thermocouples are not immune to issues like wear and drift, which can skew the data and lead to inaccurate profiles.

For example, a thermocouple exposed to repeated high-temperature cycles may experience material degradation, causing its readings to drift over time. If a thermocouple reads just 5°C lower than the actual temperature during lead-free soldering (which often requires peak temperatures around 240-260°C), it could result in incomplete solder melting and defective joints.

Understanding Wear and Drift in Thermocouples

Wear and drift are two major challenges that affect the accuracy of thermocouples in thermal profiling. Wear refers to the physical degradation of the thermocouple due to repeated exposure to high temperatures, mechanical stress, or environmental factors. Drift, on the other hand, is the gradual shift in a thermocouple's output over time, leading to inaccurate temperature readings.

Consider a manufacturing line running lead-free soldering processes daily. The thermocouples used may be subjected to temperatures exceeding 250°C for hours. Over weeks or months, the metal wires in the thermocouple can oxidize or undergo structural changes, causing drift. A study in industrial settings has shown that uncalibrated thermocouples can drift by as much as 3-5°C after 100 hours of continuous use at high temperatures, which is significant in precision processes like PCB assembly.

If this drift goes unnoticed, the thermal profile data becomes unreliable. This can lead to improper oven settings, resulting in defective products or even costly rework. Regular calibration is the key to detecting and correcting these issues before they impact production.

Why Calibration is Essential for Consistent Performance

Calibration is the process of comparing a thermocouple's readings to a known temperature standard and adjusting it to ensure accuracy. In thermal profiling, calibration is not just a one-time task; it’s a routine necessity to maintain consistent performance across production runs.

Without calibration, even small errors in temperature measurement can compound over time, leading to inconsistent soldering results. For instance, a 2°C error in the preheat zone might seem minor, but it can affect how evenly the board heats up, potentially causing thermal stress or uneven solder paste activation. Over multiple production batches, these inconsistencies can lead to higher defect rates, impacting both cost and reputation.

Calibration also ensures compliance with industry standards, especially for processes like lead-free soldering, which require tighter temperature controls due to higher melting points (typically 217-220°C for lead-free solder alloys compared to 183°C for traditional leaded solder). By regularly calibrating thermocouples, manufacturers can trust their thermal profiles to meet these stringent requirements, ensuring reliable and repeatable results.

Data Trends and the Impact of Calibration

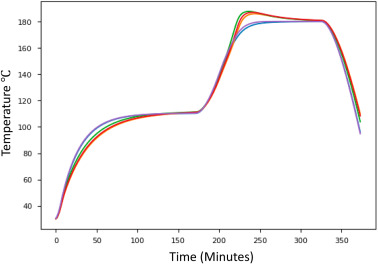

One of the most valuable aspects of thermal profiling is the ability to analyze data trends over time. By collecting and reviewing temperature data from multiple production runs, manufacturers can identify patterns, optimize oven settings, and predict potential issues before they occur. However, the reliability of these data trends depends entirely on the accuracy of the thermocouples used.

Imagine a scenario where a thermocouple drifts by 1°C per week due to wear. Over a month, the recorded data could be off by 4°C or more, leading to misleading trends. If a manufacturer relies on this data to adjust oven settings, they might inadvertently lower the temperature, thinking the profile is running too hot, when in reality, it’s the opposite. This can result in cold solder joints or other defects that are hard to trace back to the root cause.

Calibration helps maintain the integrity of data trends by ensuring that every temperature reading is accurate. With calibrated thermocouples, manufacturers can confidently use historical data to fine-tune their processes, reduce variability, and improve overall product quality.

Calibration Challenges in Lead-Free Soldering

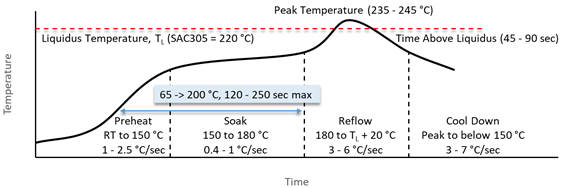

Lead-free soldering, which became widespread after the Restriction of Hazardous Substances (RoHS) directive, presents unique challenges for thermal profiling and calibration. Lead-free solder alloys, such as SAC305 (Sn96.5Ag3.0Cu0.5), have higher melting points and narrower process windows compared to traditional leaded solders. This means that even a small deviation in temperature can lead to soldering defects like insufficient wetting or thermal damage to components.

For example, the typical reflow profile for lead-free soldering requires a peak temperature between 240°C and 260°C, with a time above liquidus (TAL) of 30-90 seconds. If a thermocouple is not properly calibrated and underreads by just 3°C, the solder may not fully melt, resulting in poor joint formation. Conversely, an overreading thermocouple could push the temperature beyond safe limits, risking damage to heat-sensitive components.

Calibration is especially critical in lead-free soldering because of these tight tolerances. Regular checks and adjustments ensure that thermocouples provide accurate readings, allowing manufacturers to maintain precise control over the reflow process and meet regulatory standards.

Best Practices for Calibrating Thermocouples in Thermal Profiling

To maximize the benefits of calibration in thermal profiling, manufacturers should follow these best practices:

- Schedule Regular Calibration: Depending on usage, thermocouples should be calibrated every 3-6 months or after a set number of production cycles. High-volume production environments may require more frequent checks.

- Use Traceable Standards: Calibration should be performed using equipment traceable to national or international standards to ensure accuracy. This provides a reliable reference point for temperature measurements.

- Monitor for Wear: Inspect thermocouples for signs of physical damage or wear, such as frayed wires or oxidized tips, which can affect performance. Replace damaged sensors promptly.

- Document Results: Keep detailed records of calibration results and any adjustments made. This helps track drift over time and informs future maintenance schedules.

- Train Staff: Ensure that technicians are trained in proper calibration techniques and understand the importance of accurate thermal profiling for overall product quality.

By incorporating these practices, manufacturers can minimize the risks associated with inaccurate temperature measurements and maintain a high level of control over their soldering processes.

How Calibration Supports Long-Term Efficiency

Beyond immediate quality improvements, calibration in thermal profiling contributes to long-term efficiency in PCB manufacturing. Accurate temperature data reduces the likelihood of defects, minimizing the need for rework or scrap, which can be costly in terms of both time and materials. For instance, a single batch of defective PCBs due to poor soldering can cost thousands of dollars in rework, not to mention the potential loss of customer trust.

Additionally, consistent thermal profiles supported by calibrated thermocouples enable manufacturers to optimize oven settings for energy efficiency. By avoiding unnecessary overheating or extended cycle times, companies can reduce energy consumption while still achieving high-quality results. This is particularly important in high-volume production, where even small savings per cycle can add up significantly over time.

Calibration also plays a role in predictive maintenance. By monitoring data trends from calibrated thermocouples, manufacturers can identify when oven performance starts to deviate from the norm, allowing for proactive repairs before major issues arise. This approach helps avoid unplanned downtime and keeps production lines running smoothly.

Conclusion: Prioritizing Calibration for Better Thermal Profiling

Thermal profiling is a cornerstone of reliable PCB assembly, and calibration is the foundation that ensures its accuracy. From combating thermocouple wear and drift to maintaining consistent performance and supporting lead-free soldering, calibration is essential for producing high-quality electronics. By prioritizing regular calibration and following best practices, manufacturers can trust their thermal profiles, optimize their processes, and deliver products that meet the highest standards.

Understanding the importance of calibration in thermal profiling empowers engineers and manufacturers to tackle challenges head-on, ensuring that every solder joint is strong and every component is protected. With accurate data trends and precise temperature control, the path to efficient, defect-free production becomes clearer than ever.

ALLPCB

ALLPCB