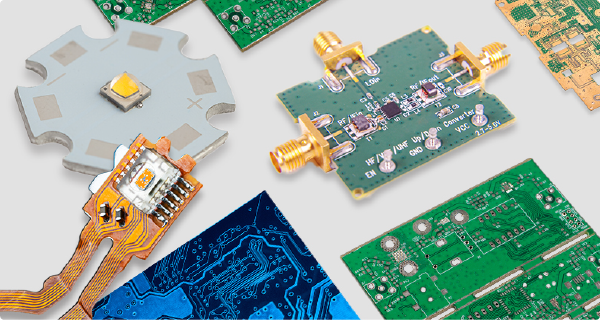

In the world of electronics manufacturing, stencil printers play a crucial role in ensuring the precision and reliability of lead-free PCB assembly. As the industry shifts away from traditional lead-based solders due to environmental and health concerns, lead-free solder paste stencil printing has become a cornerstone of modern surface mount technology (SMT). This blog post dives deep into the importance of stencil printers, the challenges of lead-free assembly, and the significance of high-temperature stencil materials in overcoming these hurdles. Whether you're an engineer or a manufacturer, understanding these elements can help optimize your PCB assembly process for better results and efficiency.

What Are Stencil Printers and Why Are They Essential?

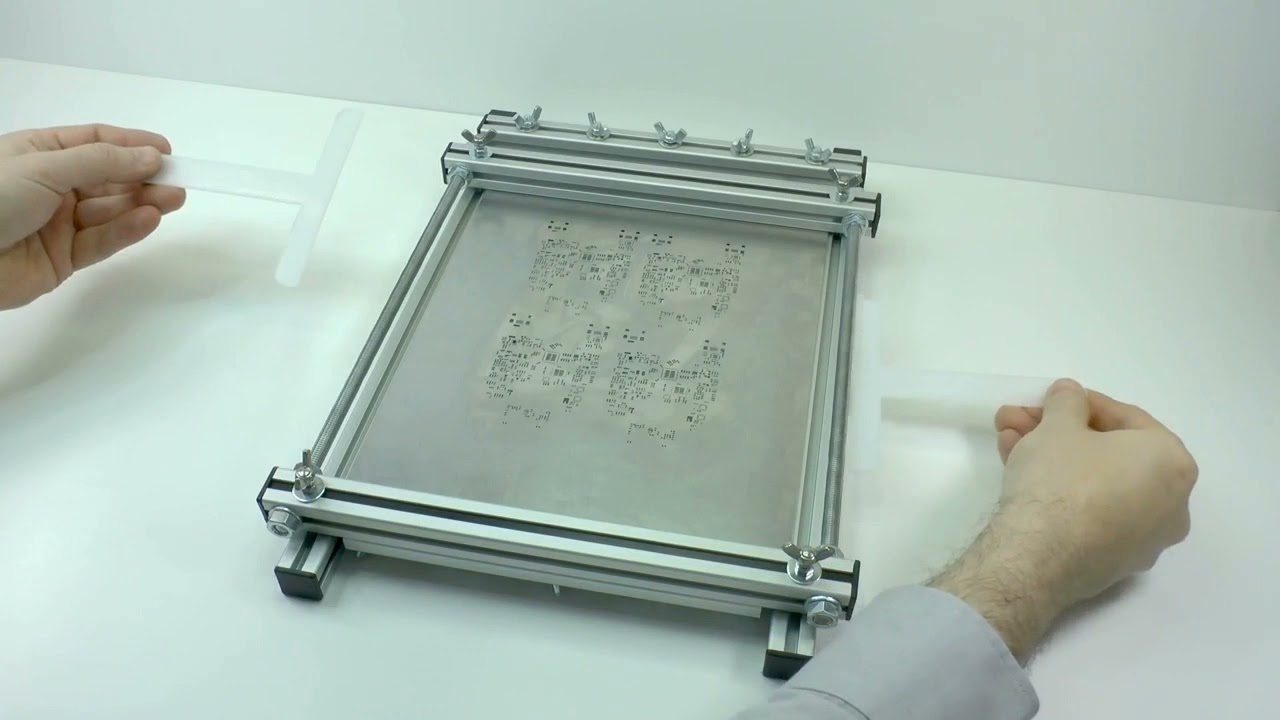

Stencil printers are specialized machines used to apply solder paste onto printed circuit boards (PCBs) during the SMT assembly process. They work by aligning a thin metal stencil, typically made of stainless steel, over the PCB. Solder paste is then spread across the stencil using a squeegee, depositing precise amounts of paste through laser-cut openings onto the board's pads where components will be placed.

In lead-free PCB assembly, stencil printers are even more critical. Lead-free solder pastes, often composed of alloys like tin-silver-copper (SAC), have different physical properties compared to traditional lead-based solders. They require precise control over deposition to prevent defects like insufficient solder or bridging. A high-quality stencil printer ensures consistent paste volume and alignment, directly impacting the quality of the final assembly.

The Shift to Lead-Free Solder Paste: Why It Matters

The transition to lead-free solder paste was largely driven by regulations like the Restriction of Hazardous Substances (RoHS) directive, which bans the use of lead in electronics due to its toxicity. While this shift benefits the environment and human health, it introduces several challenges in PCB assembly. Lead-free solders typically have higher melting points (around 217-221°C for SAC alloys compared to 183°C for lead-based solders), which means they require more heat during reflow. This can stress components and boards if not managed properly.

Additionally, lead-free solder pastes are often less forgiving in terms of wetting and flow characteristics. They may not spread as evenly, increasing the risk of defects like tombstoning (where components stand on end) or solder balling. This is where stencil printers shine—they provide the precision needed to deposit just the right amount of paste, reducing these risks and ensuring reliable connections.

Lead-Free Solder Paste Stencil Printing: Key Challenges

Lead-free solder paste stencil printing comes with a unique set of challenges that manufacturers must address to achieve high-quality results. Let’s explore some of the most common issues:

1. Higher Viscosity and Printability Issues

Lead-free solder pastes often have a higher viscosity due to their alloy composition and smaller particle sizes. This can make it harder for the paste to flow through the stencil apertures, especially for fine-pitch components with pad sizes as small as 0.3 mm. If the paste doesn’t release properly, it can lead to uneven deposits or clogged stencils, causing defects like insufficient solder or misalignment.

2. Sensitivity to Printing Parameters

The printing process for lead-free solder paste is highly sensitive to factors like squeegee pressure, speed, and stencil separation speed. For example, a squeegee pressure of 0.2-0.3 kg/cm is often recommended for fine-pitch applications, but even slight deviations can result in over- or under-deposition. Stencil printers must be finely tuned to maintain consistency across high-volume production runs.

3. Increased Wear on Stencils

Lead-free solder pastes can be more abrasive due to their metallic content, leading to faster wear on stencil materials. This wear can distort aperture shapes over time, reducing print accuracy. Manufacturers often need to replace stencils more frequently or invest in more durable, high-temperature stencil materials to withstand the rigors of lead-free assembly.

High-Temperature Stencil Materials: A Solution to Lead-Free Challenges

One of the key innovations in overcoming lead-free assembly challenges is the use of high-temperature stencil materials. Traditional stencils, often made from standard stainless steel, may not hold up under the thermal and mechanical stresses of lead-free soldering processes. Let’s look at how advanced materials help address these issues.

Why High-Temperature Materials Matter

Lead-free soldering requires higher reflow temperatures, often exceeding 240°C during peak reflow. While stencils aren’t directly exposed to the reflow oven, they must endure repeated thermal cycles during production as boards move through the assembly line. High-temperature stencil materials, such as specialized stainless steel alloys or nickel-based stencils, offer greater resistance to warping and deformation under these conditions.

Benefits of Advanced Stencil Materials

- Improved Durability: High-temperature materials resist wear and abrasion from lead-free solder pastes, extending stencil lifespan by up to 30% compared to standard materials.

- Better Aperture Precision: These materials maintain their shape and aperture accuracy even after thousands of print cycles, ensuring consistent solder paste deposition for fine-pitch components.

- Reduced Maintenance: With less frequent stencil replacement and cleaning, manufacturers can reduce downtime and improve overall production efficiency.

Investing in high-quality stencil materials is especially important for high-volume production environments where even minor defects can lead to significant losses. For instance, a defect rate of just 1% in a batch of 10,000 boards can result in 100 faulty units, costing time and resources to rework or scrap.

Lead-Free Assembly Challenges: How Stencil Printers Help Overcome Them

Beyond material considerations, stencil printers themselves are instrumental in tackling the broader challenges of lead-free PCB assembly. Here’s how they contribute to success:

1. Precision Control for Fine-Pitch Components

As electronics become smaller and more complex, components with ultra-fine pitch (spacing as low as 0.4 mm) are increasingly common. Stencil printers with advanced vision systems and automated alignment can achieve placement accuracy within 25 microns, ensuring solder paste is applied exactly where it’s needed. This precision is vital for preventing defects in lead-free assemblies where tolerances are tight.

2. Consistency in High-Volume Production

In high-volume manufacturing, maintaining consistency across thousands of boards is a challenge. Modern stencil printers are equipped with programmable settings to control variables like squeegee pressure (typically 0.2-0.5 kg/cm) and print speed (20-50 mm/s). This automation minimizes human error and ensures every board receives the same quality of solder paste application, even with the trickier flow properties of lead-free pastes.

3. Reducing Defects Through Closed-Loop Systems

Many advanced stencil printers feature closed-loop feedback systems that monitor paste deposition in real-time. If a print falls outside acceptable parameters—such as a paste height deviation of more than 10%—the system can automatically adjust settings or alert operators. This is particularly useful for lead-free solder pastes, which are prone to inconsistent release from stencil apertures.

Best Practices for Optimizing Stencil Printing in Lead-Free Assembly

To maximize the effectiveness of stencil printers in lead-free PCB assembly, manufacturers should follow these best practices:

- Regular Stencil Cleaning: Clean stencils after every 5-10 prints to prevent paste buildup, using automated under-stencil cleaning systems if possible.

- Optimize Solder Paste Storage: Store lead-free solder paste at 2-10°C and allow it to reach room temperature (around 25°C) for 4-6 hours before use to ensure proper viscosity.

- Monitor Environmental Conditions: Maintain a controlled environment with humidity levels of 40-60% and temperatures of 22-28°C to prevent paste drying or moisture absorption.

- Use Proper Stencil Thickness: Choose a stencil thickness (typically 0.1-0.15 mm for fine-pitch components) that balances paste volume with release characteristics.

By implementing these practices, manufacturers can reduce defect rates by as much as 20-30%, based on industry studies, leading to higher yields and lower production costs.

The Future of Stencil Printing in Lead-Free Assembly

As the electronics industry continues to evolve, stencil printing technology is advancing to meet new demands. Innovations like 3D stencil printing and jet printing are emerging as alternatives for ultra-fine pitch applications, allowing for variable paste heights and eliminating the need for traditional stencils in some cases. Additionally, the development of eco-friendly lead-free solder pastes with improved printability is helping to reduce assembly challenges.

High-temperature stencil materials will also continue to play a key role as manufacturers push for faster, hotter reflow processes to keep up with production demands. Staying ahead of these trends means investing in cutting-edge stencil printers and materials that can handle the unique requirements of lead-free assembly.

Conclusion

Stencil printers are indispensable in the world of lead-free PCB assembly, providing the precision and consistency needed to navigate the challenges of lead-free solder paste stencil printing. From addressing the higher viscosity and thermal demands of lead-free alloys to leveraging high-temperature stencil materials for durability, these machines and materials are at the heart of modern SMT production. By understanding their role and adopting best practices, manufacturers can achieve defect-free assemblies, improve efficiency, and stay competitive in an ever-changing industry.

At ALLPCB, we’re committed to supporting your PCB assembly needs with state-of-the-art solutions and expert guidance. Whether you’re tackling lead-free assembly challenges or optimizing your stencil printing process, our team is here to help you succeed with reliable, high-quality results.

ALLPCB

ALLPCB