If you're wondering whether to use solder paste or solder wire for your next project, the answer depends on your specific soldering method and application. Solder paste is ideal for surface-mount technology (SMT) and automated processes, offering precision for small components. Solder wire, on the other hand, excels in hand soldering and through-hole technology (THT), providing control and flexibility for larger joints. In this detailed guide, we'll break down the differences, benefits, and best use cases for each, helping you make the right choice for your PCB assembly or repair tasks.

Introduction to Soldering Materials

Soldering is a fundamental skill in electronics, used to create strong electrical connections between components and printed circuit boards (PCBs). The two most common materials for soldering are solder paste and solder wire. While both serve the same core purpose—joining metal surfaces—they differ significantly in form, application, and suitability for various tasks. Understanding these differences is crucial for achieving reliable results, whether you're working on a small hobby project or a large-scale manufacturing process.

In this blog, we'll compare solder paste vs. solder wire, explore their unique benefits, and guide you on when to use solder paste or when to use solder wire. We'll also dive into different soldering methods to help you select the best option for your needs.

What Is Solder Paste?

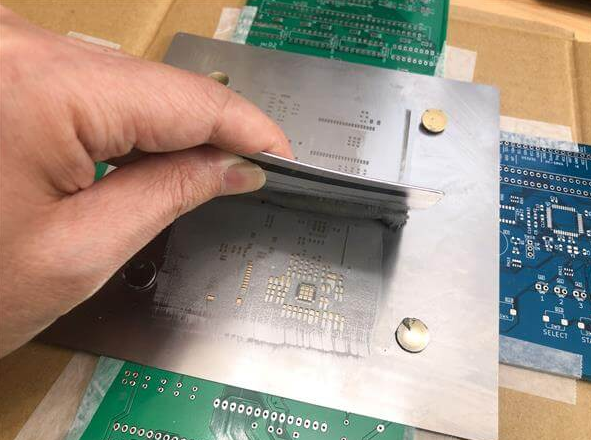

Solder paste is a mixture of tiny solder alloy particles suspended in a flux medium. This paste-like substance is typically used in SMT applications, where components are placed directly onto the surface of a PCB. The flux in the paste helps clean the metal surfaces, ensuring a strong bond when the solder melts during the reflow process.

Solder paste is often applied using a stencil or syringe, allowing for precise placement on small pads. Once heated in a reflow oven or with a hot air gun, the paste melts and forms a solid connection between the component and the board. Common alloy compositions include tin-lead (SnPb) or lead-free options like tin-silver-copper (SAC), with melting points ranging from 183°C to 217°C depending on the mix.

Solder Paste Benefits

- Precision: Solder paste is perfect for tiny components, such as 0402 or 0201 resistors, where accuracy is critical. It can be applied in exact amounts using stencils, reducing waste and ensuring consistent results.

- Automation-Friendly: It’s widely used in automated assembly lines, where machines place components and reflow ovens heat the paste for mass production.

- Reduced Manual Effort: Since the paste is pre-applied, there's no need to manually feed solder during the process, saving time in high-volume manufacturing.

- Flux Integration: The built-in flux eliminates the need for a separate flux application, streamlining the soldering process.

What Is Solder Wire?

Solder wire is a thin, flexible strand of solder alloy, often with a flux core running through its center. It’s the go-to choice for hand soldering, where a soldering iron is used to melt the wire directly onto a joint. Solder wire is commonly used for through-hole components, repairs, and prototyping due to its ease of use and control.

The wire comes in various diameters, typically ranging from 0.5mm to 1.5mm, allowing users to choose the right size for their project. Like solder paste, it’s available in both leaded and lead-free compositions, with melting points similar to those of paste (183°C for SnPb, higher for lead-free).

Solder Wire Benefits

- Control: Solder wire gives you direct control over how much solder is applied to a joint, making it ideal for manual soldering tasks.

- Versatility: It works well for a wide range of applications, from large through-hole joints to small surface-mount repairs with a fine-tip iron.

- Cost-Effective for Small Projects: Solder wire is generally less expensive than paste for low-volume or one-off tasks, as it doesn’t require specialized equipment like stencils or reflow ovens.

- Ease of Use: Beginners often find solder wire more intuitive, as it can be melted and applied with a basic soldering iron without complex setup.

Solder Paste vs. Solder Wire: Key Differences

While both materials are used for soldering, their physical properties and applications set them apart. Let’s break down the key differences between solder paste vs. solder wire to help you decide which is better for your project.

| Feature | Solder Paste | Solder Wire |

|---|---|---|

| Form | Paste (alloy particles in flux) | Solid wire (often with flux core) |

| Application Method | Stencil, syringe, or dispenser | Manual application with soldering iron |

| Best For | SMT components, automated assembly | Through-hole, repairs, prototyping |

| Precision | High (ideal for tiny components) | Moderate (depends on user skill) |

| Equipment Needed | Reflow oven or hot air gun, stencil | Soldering iron |

| Cost | Higher for small-scale use | Lower for small-scale use |

This comparison highlights that your choice between solder paste or wire largely depends on the type of components you're working with and the scale of your project.

When to Use Solder Paste

Knowing when to use solder paste can save you time and improve the quality of your work. Here are the scenarios where solder paste shines:

- Surface-Mount Technology (SMT): If you're working with surface-mount components like chip resistors, capacitors, or ICs, solder paste is the best choice. Its ability to be applied precisely to small pads ensures clean, reliable joints after reflow. For instance, in a typical SMT assembly, solder paste can achieve joint heights of 0.05mm to 0.15mm, perfect for compact designs.

- High-Volume Production: In manufacturing environments, solder paste is used with automated pick-and-place machines and reflow ovens. This setup can handle thousands of boards per hour, with defect rates often below 1% when optimized.

- Fine-Pitch Components: For components with closely spaced leads (e.g., 0.5mm pitch QFP packages), solder paste applied via stencil prevents bridging and ensures even distribution.

When to Use Solder Wire

Understanding when to use solder wire is just as important. Here are the ideal situations for using solder wire:

- Through-Hole Technology (THT): For components with leads that go through the PCB, like connectors or large capacitors, solder wire is perfect. It allows you to fill the hole and create a strong mechanical bond, often with shear strengths exceeding 10 MPa for a well-made joint.

- Repairs and Rework: If you need to fix a broken joint or replace a component, solder wire offers the control needed to apply just the right amount of material. It’s especially useful with a soldering iron tip temperature of 300°C to 350°C for quick melting.

- Prototyping and Hobby Projects: For small-scale or one-off projects, solder wire is more practical and cost-effective. A 0.8mm diameter wire, for example, works well for most general-purpose soldering tasks on breadboards or simple circuits.

Soldering Methods: Paste vs. Wire in Practice

Different soldering methods align with the use of solder paste or wire. Let’s explore how each material fits into common techniques.

Reflow Soldering (Solder Paste)

Reflow soldering is the primary method for solder paste. In this process, paste is applied to PCB pads, components are placed, and the board is heated in a reflow oven. The heat melts the paste, creating solid joints as it cools. This method is standard in SMT assembly, with typical reflow profiles reaching peak temperatures of 240°C to 260°C for lead-free solder. It’s highly efficient for mass production but requires specialized equipment.

Hand Soldering (Solder Wire)

Hand soldering with solder wire involves using a soldering iron to melt the wire onto a joint. This method is ideal for through-hole components, repairs, and small-scale projects. It requires skill to avoid cold joints or overheating components, but it’s accessible with minimal equipment. A typical soldering iron operates at 25W to 40W for most electronics work, providing enough heat to melt wire at 183°C to 217°C.

Hot Air Rework (Both Paste and Wire)

Hot air rework stations can be used with both solder paste and wire, depending on the task. For paste, hot air can reflow small areas during repairs. For wire, it can help desolder components by melting existing joints. Hot air tools often operate at 300°C to 400°C, with airflow settings of 20 to 50 liters per minute for precise control.

Choosing Between Solder Paste and Solder Wire: Practical Tips

Here are some actionable tips to help you decide between solder paste or wire based on your project requirements:

- Component Size: Use solder paste for components smaller than 1mm in size or with fine pitch leads. Opt for solder wire for larger components or through-hole designs.

- Volume of Work: If you're assembling more than 10 boards or working with SMT, invest in solder paste and the necessary tools. For one-off tasks or repairs, stick with solder wire.

- Skill Level: Beginners may find solder wire easier to handle with a basic soldering iron. Solder paste requires learning to use stencils and reflow equipment.

- Budget: Solder wire setups (iron and wire) can cost as little as $20 to $50, while solder paste setups (stencils, ovens) often start at $100 or more for small-scale use.

Conclusion: Making the Right Choice for Your Soldering Needs

Deciding between solder paste vs. solder wire comes down to your project’s specific needs. Solder paste offers unmatched precision and efficiency for SMT and high-volume production, making it the go-to choice for modern electronics assembly. Solder wire, with its versatility and ease of use, remains essential for hand soldering, through-hole components, and quick fixes.

By understanding the solder paste benefits and solder wire benefits, as well as knowing when to use solder paste or when to use solder wire, you can achieve better results in your soldering projects. Whether you're a hobbyist building a prototype or a professional optimizing a production line, selecting the right material and soldering method will ensure strong, reliable connections every time.

At ALLPCB, we’re committed to supporting your electronics projects with high-quality materials and services. Whether you need guidance on soldering techniques or top-notch PCB manufacturing, we’re here to help you succeed.

ALLPCB

ALLPCB