When it comes to PCB assembly, one of the biggest decisions you'll face is choosing between Surface Mount Technology (SMT) and Through-Hole Technology (THT). Both methods have their strengths, but cost often plays a decisive role. So, which is more cost-effective for your project? In short, SMT assembly cost is generally lower for high-volume production due to automation and smaller component sizes, while through-hole assembly cost can be more economical for low-volume or prototype builds where durability and manual assembly are prioritized. In this detailed comparison, we'll break down the factors influencing SMT assembly cost, through-hole assembly cost, and help you make an informed decision for your next project.

Introduction to PCB Assembly Methods

Printed Circuit Board (PCB) assembly is the process of attaching electronic components to a board to create a functional circuit. The two primary methods for this are SMT and Through-Hole. Each approach has unique characteristics that impact design, performance, and most importantly, cost. Understanding these differences is key to selecting the right method for your needs. In this blog, we'll dive deep into a PCB assembly comparison, focusing on surface mount technology pricing and the overall cost-effectiveness of each method. Whether you're an engineer, a product designer, or a business owner, this cost-effective PCB assembly guide will help you navigate your options with confidence.

What is Surface Mount Technology (SMT)?

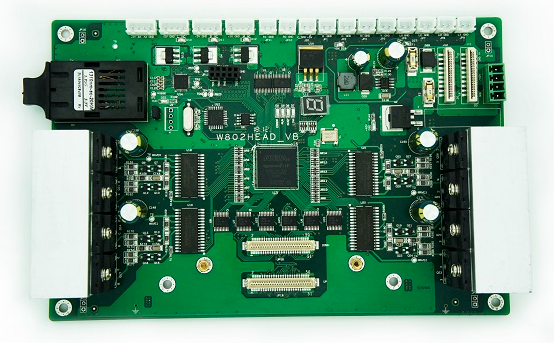

Surface Mount Technology involves placing components directly onto the surface of a PCB. These components, known as surface-mount devices (SMDs), are typically smaller than their through-hole counterparts. SMT relies heavily on automated assembly processes, using machines to precisely place and solder components. This method is widely used in modern electronics due to its ability to support compact designs and high-speed production.

The SMT assembly cost is often lower in large-scale production because automation reduces labor expenses. Additionally, SMDs are generally cheaper than through-hole components due to their smaller size and widespread availability. However, initial setup costs for SMT, such as creating stencils for solder paste application, can be higher, especially for smaller runs.

What is Through-Hole Technology (THT)?

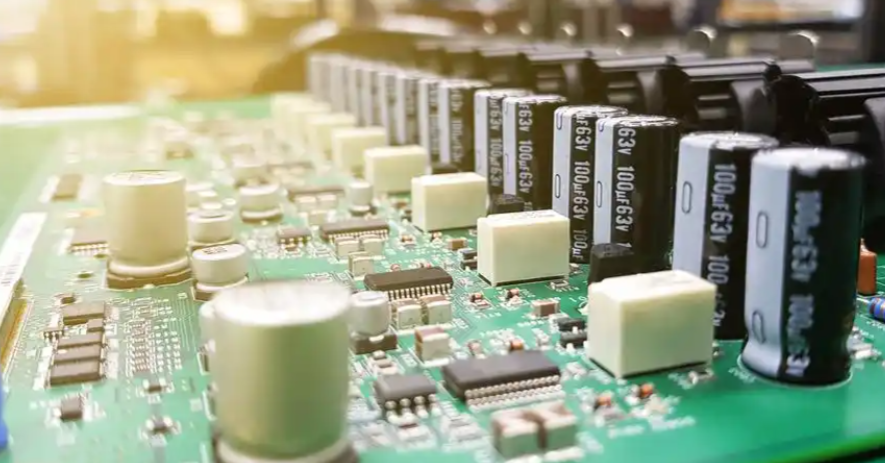

Through-Hole Technology, on the other hand, involves inserting component leads through holes drilled into the PCB and soldering them on the opposite side. This method has been around for decades and is known for its durability and strong mechanical connections. Through-hole components are often larger and can handle higher power or stress, making them ideal for certain applications like power supplies or industrial equipment.

The through-hole assembly cost tends to be higher in mass production due to the manual labor often required for insertion and soldering. However, for low-volume projects or prototypes, THT can be more cost-effective since it doesn't require expensive setup processes like SMT does. The trade-off is that through-hole designs take up more space on the PCB, potentially increasing material costs.

Key Factors Influencing SMT Assembly Cost

When evaluating surface mount technology pricing, several factors come into play. Understanding these can help you estimate costs more accurately and optimize your budget for cost-effective PCB assembly.

- Component Costs: SMDs are typically less expensive than through-hole components because they are smaller and produced in higher volumes. For example, a standard SMD resistor might cost as little as $0.01 per unit in bulk, while a through-hole resistor could cost $0.05 or more.

- Automation: SMT assembly is highly automated, using pick-and-place machines and reflow ovens. This reduces labor costs significantly for high-volume orders. A fully automated SMT line might handle thousands of boards per day with minimal human intervention.

- Setup Costs: SMT requires initial investments like stencil creation for solder paste application, which can cost between $50 and $200 depending on the complexity of the design. For small runs, this upfront cost can make SMT less attractive.

- Board Size and Density: SMT allows for smaller, more densely packed boards, which can reduce material costs. A smaller PCB might save you $0.50 to $1.00 per board in material expenses compared to a larger through-hole design.

Key Factors Influencing Through-Hole Assembly Cost

Through-hole assembly cost is influenced by different factors, often tied to the manual processes and physical characteristics of the components. Here's a breakdown of what drives these costs:

- Component Costs: Through-hole components are generally more expensive due to their larger size and lower production volumes. For instance, a through-hole capacitor might cost $0.10 per unit, while an equivalent SMD capacitor could be half that price.

- Labor Costs: THT often requires manual insertion and soldering, especially for low-volume or custom projects. Manual labor can add $1 to $5 per board, depending on the complexity and region.

- Setup Costs: Unlike SMT, through-hole assembly doesn't typically require costly stencils or specialized machinery for small runs, making it more accessible for prototypes. Setup costs might be as low as $10 to $50 for basic projects.

- Board Size: Through-hole components take up more space, often requiring larger boards. This can increase material costs by 10-20% compared to an SMT design with the same functionality.

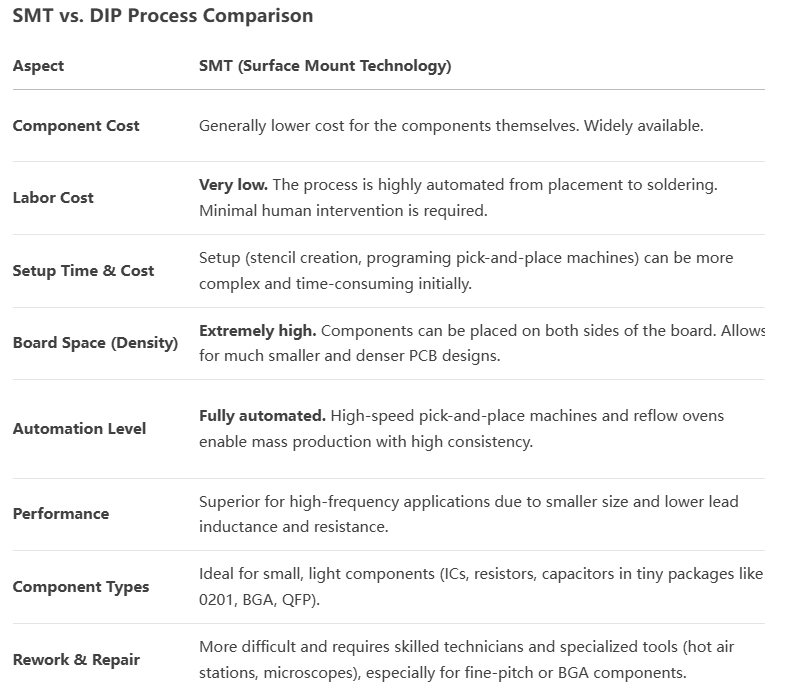

PCB Assembly Comparison: SMT vs. Through-Hole Costs

Now that we've covered the individual factors, let's dive into a direct PCB assembly comparison focusing on cost. We'll look at different scenarios to illustrate when each method might be more cost-effective.

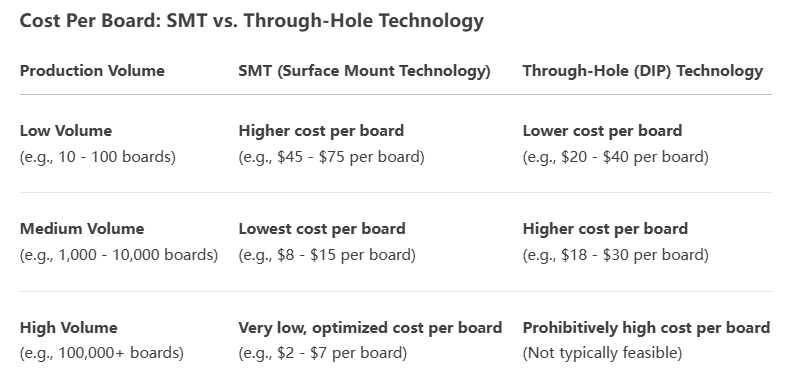

Low-Volume Production (1-100 Units)

For small runs or prototypes, through-hole assembly often has a cost advantage. The lack of expensive setup processes means you can get started with minimal upfront investment. For example, assembling 50 boards with through-hole components might cost around $200-$300 in total, including labor and materials. In contrast, SMT assembly for the same quantity could cost $300-$500 due to stencil costs and machine setup fees, even though component costs are lower.

Medium-Volume Production (100-1,000 Units)

In this range, costs start to balance out. SMT begins to show its advantages as automation reduces per-unit labor costs. For 500 boards, SMT assembly cost might average $1.50 per board, totaling $750, while through-hole assembly could be closer to $2.00 per board, totaling $1,000. The savings from smaller board sizes and cheaper components in SMT start to outweigh the initial setup expenses.

High-Volume Production (1,000+ Units)

For large-scale production, SMT is almost always the more cost-effective PCB assembly option. Automation drives down labor costs to mere cents per board, and bulk component pricing further reduces expenses. For 10,000 boards, SMT might cost $0.80 per board ($8,000 total), while through-hole could be $1.50 per board ($15,000 total) due to ongoing manual labor and larger material needs.

Other Cost Considerations Beyond Assembly

While assembly costs are a major factor, other elements can influence the overall budget for your PCB project. Let's explore a few additional areas where SMT and Through-Hole differ.

Design and Layout Costs

SMT designs often require more precise layouts due to the smaller components and tighter spacing. This can increase design time and software costs, potentially adding $100-$500 to your project budget for complex boards. Through-hole designs are generally simpler and less costly to layout, often saving 10-20% on design expenses.

Testing and Quality Control

SMT boards, with their compact designs, can be harder to test and repair. Specialized equipment like automated optical inspection (AOI) systems might be needed, costing an additional $0.10-$0.50 per board for high-volume runs. Through-hole boards are easier to inspect and rework manually, often keeping testing costs lower at around $0.05-$0.20 per board.

Durability and Rework Costs

Through-hole components are more durable under physical stress, reducing the likelihood of failures and costly rework. SMT components, while reliable in most cases, can be more prone to damage during handling or thermal stress, potentially adding $0.20-$1.00 per board in rework costs if issues arise during production.

When to Choose SMT for Cost-Effective PCB Assembly

SMT is often the better choice for cost-effective PCB assembly in the following scenarios:

- High-Volume Production: If you're producing thousands of units, the automation and lower component costs of SMT will save you significantly.

- Compact Designs: When space is a premium, SMT allows for smaller boards, reducing material costs.

- Modern Electronics: Most consumer electronics, like smartphones or wearables, rely on SMT for its speed and efficiency.

When to Choose Through-Hole for Cost-Effective PCB Assembly

Through-Hole might be the more cost-effective option in these situations:

- Low-Volume or Prototyping: For small runs, the lower setup costs of THT make it more economical.

- High-Power Applications: If your project involves high power or mechanical stress, through-hole's durability can prevent costly failures.

- Manual Assembly Needs: If automation isn't an option, through-hole components are easier to work with by hand.

Tips for Reducing PCB Assembly Costs

Regardless of whether you choose SMT or Through-Hole, there are ways to optimize your project for cost-effective PCB assembly:

- Optimize Component Selection: Use standard, widely available components to keep costs down. Avoid rare or specialized parts unless absolutely necessary.

- Plan for Volume: If you anticipate scaling up production, design for SMT from the start to avoid redesign costs later.

- Minimize Board Layers: Reducing the number of layers in your PCB can save 10-30% on material and manufacturing costs.

- Work with Experts: Partner with a reliable assembly service to streamline the process and avoid costly mistakes during production.

Conclusion: Making the Right Choice for Your Budget

Choosing between SMT and Through-Hole for your PCB assembly comes down to understanding your project's needs and budget. SMT assembly cost shines in high-volume, compact designs where automation drives down expenses. Through-hole assembly cost, however, can be more attractive for low-volume or durable applications where setup simplicity and mechanical strength matter most. By carefully evaluating production volume, component needs, and design requirements, you can achieve cost-effective PCB assembly tailored to your goals.

At ALLPCB, we're committed to helping you navigate these decisions with expert guidance and top-notch assembly services. Whether you're leaning toward SMT or Through-Hole, our team is ready to support your project from design to delivery with solutions that balance cost and quality.

ALLPCB

ALLPCB